Gas base permeation reactor

A gas-based infiltration and reactor technology, applied in the field of metallurgy, can solve problems such as unfavorable long-term development, increase cost investment, prolong operation time, etc., and achieve the effects of avoiding cumbersome and complicated, increasing effective contact area, and improving reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

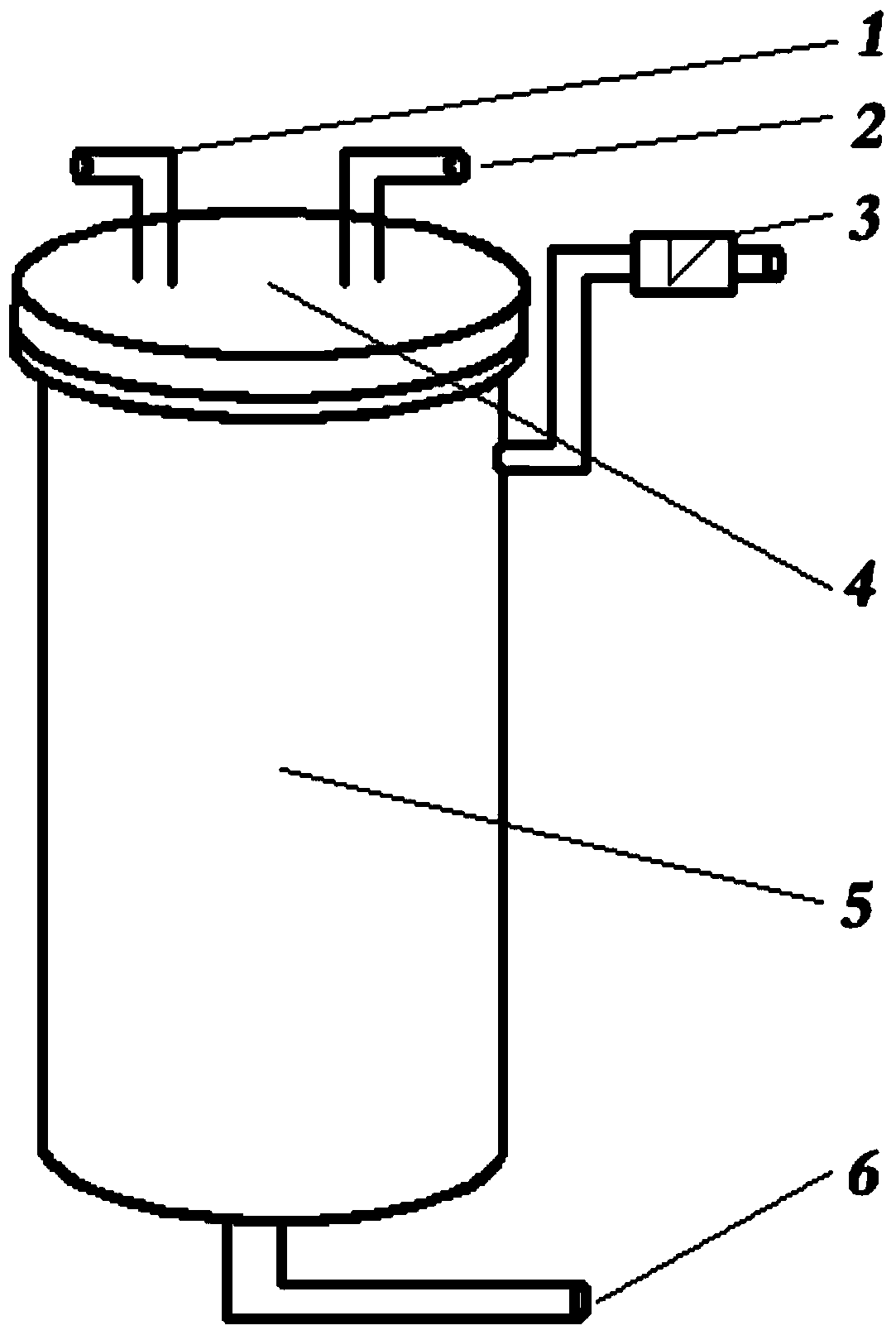

[0019] In Figure-1, the cooling water inlet 1 and the cooling water outlet 2 are welded on the reactor water-cooled furnace cover 4 and the reactor main body 5 is sealed and connected by bolts through gaskets, and the gas-based pressure stabilizing valve 3 is installed on the upper half of the reactor main body 5 part, it usually requires very stable working performance to ensure that the rare earth ore powder is not blown up by the variable pressure airflow, the reducing gas inlet 6 is welded at the bottom of the reactor main body 5, and the reducing gas (H 2 , CO, CH 4 ) from here.

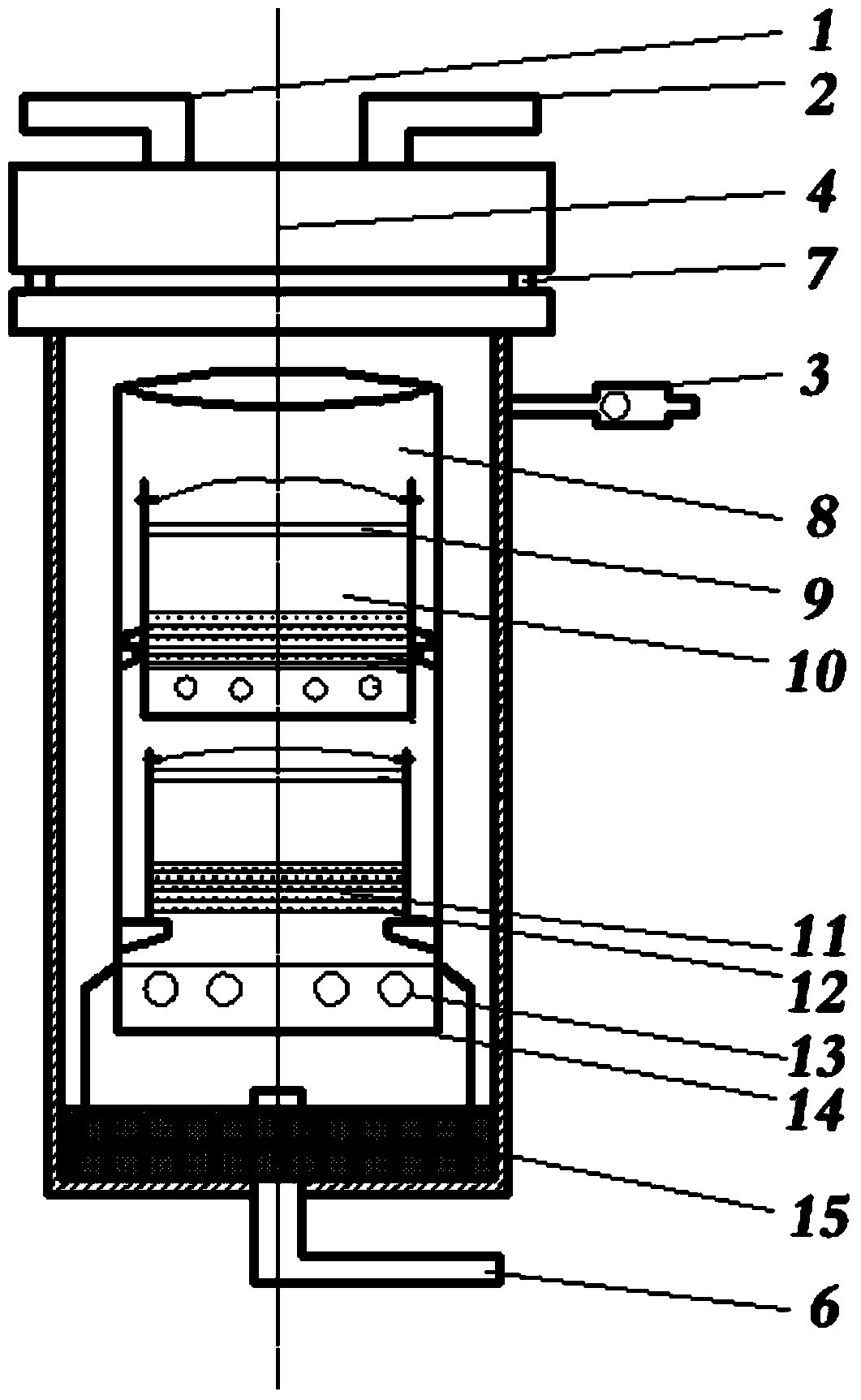

[0020] In the embodiment shown in Figure-2, all reactor components are made of steel, and the main body 5 of the gas-based permeation reactor is a cylinder with a volume of 1.9635L (diameter D is 10cm and height H is 25cm); the reactor The lower part of the main body 5 is provided with a sealing material 15, and the sealing material 15 is made of alumina powder. At least one small sleeve for r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com