An oil tank sealing door panel device for large electric discharge machine tools

A technology of electric discharge machine tool and door panel, which is applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc. It can solve the problems of simultaneous drive of both ends and difficult self-locking sealing, etc., and achieves good sealing effect, simple structure and reliability sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

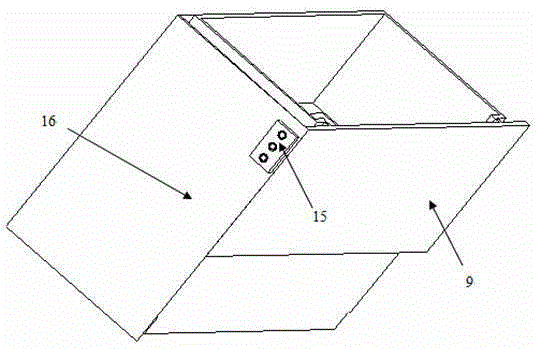

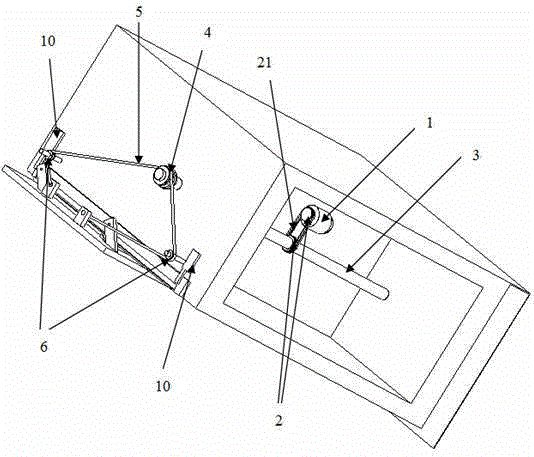

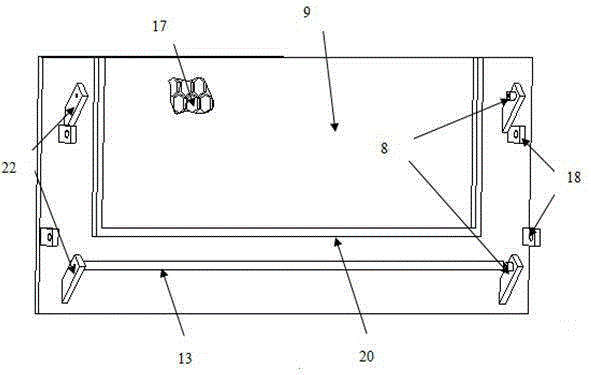

[0018] The present invention is a sealed oil tank door panel device for a large electric discharge machine tool, which is characterized in that it includes a power system, a transmission system, an execution system, and a control system, wherein the power system includes a motor 1, and the transmission system includes a transmission mechanism, a transmission shaft 3, and a wire rope winch 4. Wire rope 5, fixed pulley 6, the execution system includes guide groove 7, guide wheel 8, door panel 9, door panel buckle wedge structure 13, machine bed buckle wedge structure 14, control system includes limit switch 10, reversing switch 15 , wherein the motor 1 is installed on the workbench 12, the output shaft of the motor 1 is connected with the transmission shaft 3 through the transmission mechanism, the transmission shaft 3 runs through the workbench 12 left and right, the wire rope winch 4 is fixed on both ends of the transmission shaft 3, and the fixed pulley 6 is The shaft is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com