A kind of preparation method of eucalyptus finger ground floor

A technology for eucalyptus wood and flooring, which is used in the joining of wooden veneers, humidity-conditioning wood, and manufacturing tools, etc., can solve the problems of difficult paint quality, poor sanding performance of eucalyptus wood, rough end processing, etc. Achieve the effect of solving the problem of fiber tearing and roughness, reducing the cost of sanding, and improving the strength of finger joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

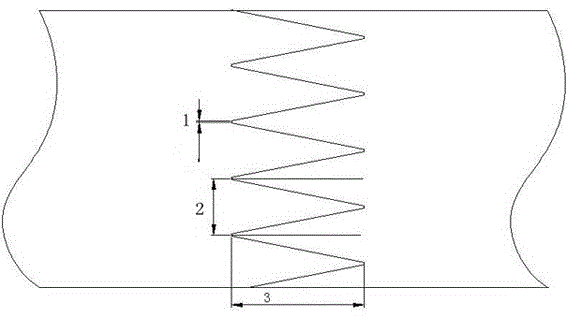

[0034] Control attachedfigure 1 In this embodiment, the eucalyptus finger-joined floor is composed of a plurality of finger-joined wood chips. The finger-jointed wood chips can be of various specifications and sizes, and the eucalyptus sawn timber after carbonization and moisture resurgence are sawed in different ways according to product requirements. The finger-joined wood chips are cuboid wood blocks, equal in width and thickness, and have finger-shaped teeth on the two short sides of the finger-joined wood chips. The tooth shapes of the finger-shaped teeth on each finger-joined wood chip are exactly the same, so the Wood pieces can be fully meshed. A plurality of finger-joined wood chips are joined to form a finger-joined strip, and then the finger-joined strips are glued in parallel to form a finger-jointed board.

[0035] The concrete preparation steps of described eucalyptus finger ground floor are:

[0036] S1. Log sawing: Cut the log into 1m-long wood sections, and ...

Embodiment 2

[0054] S1. Log sawing: Cut the log into 1m-long wood sections, and use a band saw to cut it into slats with a width of 50mm and a thickness of 23mm;

[0055] S2. Drying: After stacking the sawed slats, place a heavy object on the top of the pile, and then use a forklift to load the eucalyptus slats into the drying kiln. When the moisture content is above 40%, the temperature in the kiln is controlled at 40°C. Humidity 92%; when the moisture content is 30-40%, the temperature in the kiln is controlled at 45°C, and the relative humidity is 85%; when the moisture content is 20-30%, the temperature in the kiln is controlled at 48°C, and the relative humidity is 75%; When ~20%, the temperature in the kiln is controlled at 55°C and the relative humidity is 65%; when the moisture content is less than 10%, the temperature in the kiln is controlled at 60°C and the relative humidity is 35%; dry until the moisture content is below 8%.

[0056] S3. Material selection: remove cracks and kn...

Embodiment 3

[0072] S1. Log sawing: cut the log into 1m-long wood sections, and use a band saw to cut it into slats with a width of 50mm and a thickness of 23mm;

[0073] S2. Drying: After stacking the sawed slats, place heavy objects on the top of the pile, and then use a forklift to load the eucalyptus slats into the drying kiln. When the moisture content is above 40%, the temperature in the kiln is controlled at 40°C. Humidity 92%; when the moisture content is 30-40%, the kiln temperature is controlled at 45°C, and the relative humidity is 85-88%; when the moisture content is 20-30%, the kiln temperature is controlled at 48°C, and the relative humidity is 75-78%; When the moisture content is 10-20%, the temperature in the kiln is controlled at 55°C, and the relative humidity is 60-65%. When the moisture content is less than 10%, the temperature in the kiln is controlled at 60°C, and the relative humidity is 35-40%. %the following.

[0074] S3. Material selection: remove cracks and knot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com