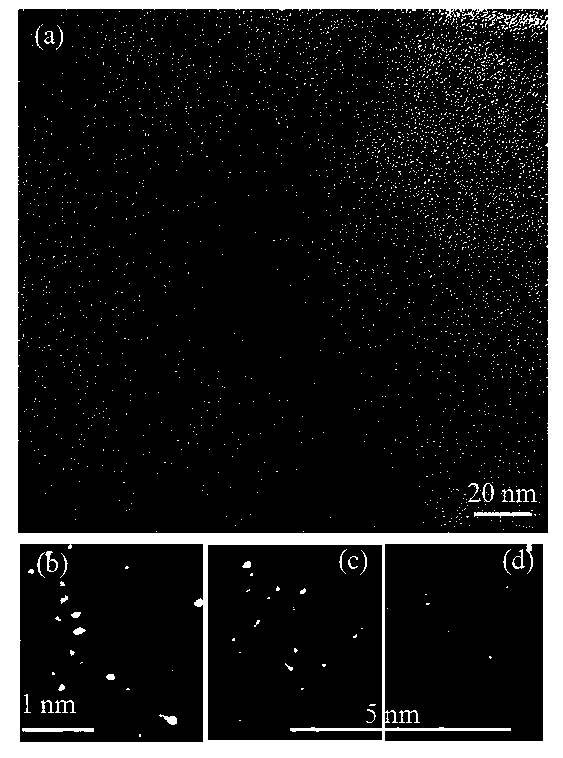

Method for preparing 3C-SiC nanoparticles 2nm in grain size through laser ablation process

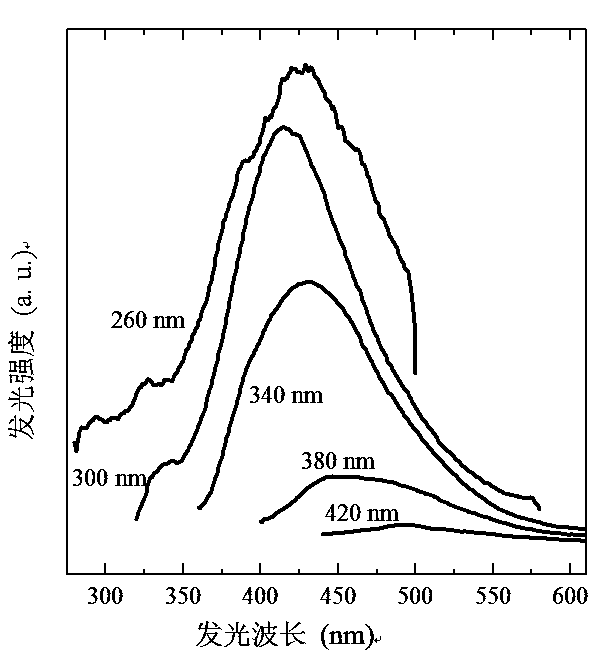

A technology of nanoparticle and laser ablation, which is applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science. It can solve the problem of uneven size of 3C-SiC nanoparticles and achieve strong and stable light emission. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The raw material involved in the invention is a 6H-SiC polycrystalline ceramic sheet with a thickness of 1-4 mm and a diameter of more than 2.0 cm. Absolute ethanol and acetone used for cleaning were of analytical grade. The laser used is COMPexPro201 type excimer pulsed pulsed laser.

[0019] First, the commercially available 6H-SiC polycrystalline ceramic sheet was ultrasonically cleaned in deionized water, absolute ethanol, and acetone for 5-10 minutes, and dried with a hair dryer or nitrogen flow. Place it again in deionized water for 3-5 minutes, and then clean the residual organic matter for later use. Then put the cleaned 6H-SiC polycrystalline ceramic sheet in a beaker, add deionized water, the water surface is 4-5 mm higher than the upper surface of the 6H-SiC polycrystalline ceramic sheet. The beaker is placed on a separately controllable mobile platform in the X, Y, and Z directions. The X and Y directions are moved back and forth through the control progra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com