Method for recovering germanium from germanium-containing multi-metal material

A multi-metal and material technology, applied in the field of germanium recovery, can solve the problems of intractable extraction, large environmental impact, and low recovery rate of germanium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

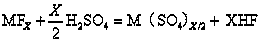

Method used

Image

Examples

Embodiment 1

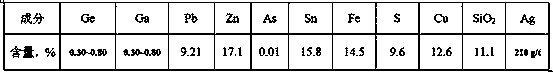

[0040] Embodiment 1: A method for recovering germanium from germanium-containing polymetallic materials, wherein the main chemical components of germanium-containing polymetallic materials are shown in the table below.

[0041]

[0042] The specific recycling steps are as follows:

[0043] In the first step, in a 3000L reactor for chemical distillation, take 500kg of multi-metal materials containing 0.40% germanium, the amount of germanium metal is 2.0 kg, add 500L of tap water, start stirring, and dissolve and disperse the multi-metal materials containing germanium Finally, add 500L of industrial hydrochloric acid with a concentration of 10 mol / L.

[0044] In the second step, after the reaction until the solution no longer produces gas, slowly add 25kg of ammonium fluoride solid, and control the reaction temperature of the solution at 45-55°C.

[0045] In the third step, after 1 hour of reaction, slowly add 20 kg of potassium permanganate to further oxidize and decompose ...

Embodiment 2

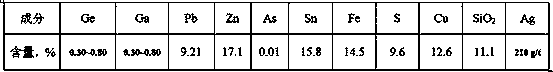

[0051] Embodiment 2: A method for recovering germanium from germanium-containing polymetallic materials, wherein the main chemical components of germanium-containing polymetallic materials are shown in the table below.

[0052]

[0053] The specific recycling steps are as follows:

[0054] In the first step, take 500kg of multi-metal material containing 0.70% germanium in a 3000L reaction kettle for chemical distillation, and add 750L of tap water with the amount of germanium metal being 3.5 kg. Start stirring to dissolve and disperse the germanium-containing polymetallic material, and then add 750L of industrial hydrochloric acid with a concentration of 10 mol / L.

[0055] In the second step, after the reaction until the solution no longer produces gas, slowly add 37.5kg of ammonium fluoride solid, and control the reaction temperature of the solution at 45-55°C.

[0056] In the third step, after 1 hour of reaction, slowly add 30 kg of potassium permanganate to further oxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com