Temperature measuring device on motion device and temperature measuring method of temperature measuring device

A temperature measurement and movement device technology, applied in the direction of temperature measurement of moving solids, etc., can solve the problems of not being able to truly reflect the internal temperature of the material, the service life of the temperature measurement device is low, and the power supply is difficult to arrange, etc., to achieve ingenious design, fast response time, Solve the effect that is easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

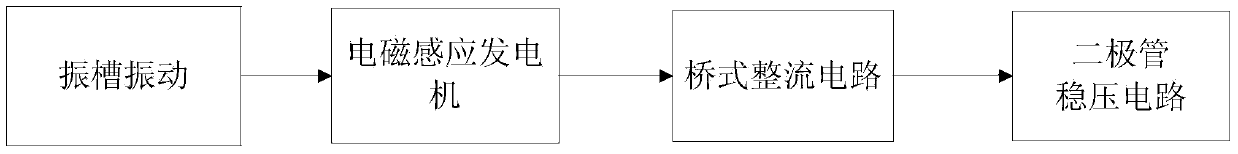

[0039] This embodiment provides a temperature measuring device on a moving device, specifically a temperature measuring device on a vibrating tank, where the vibrating tank is a commonly used conveying device in the field of tobacco processing, and placed on the vibrating tank Materials, such as shredded tobacco, cut stems, etc., are conveyed by the vibrating trough, vibrating while conveying. The temperature measurement device in this embodiment includes a power generation device 1 and a temperature acquisition device 2, and the power generation device 1 is arranged at the tail of the vibrating tank. The vibrating tank needs regular maintenance and cleaning. When cleaning, it needs to be washed with water and hard objects to remove smoke and dirt. Installing at the tail of the vibrating tank can avoid damage to the power generation device during maintenance and cleaning. post-maintenance, such as Figure 4 shown. The power generating device 1 includes a generator, a rectifi...

Embodiment 2

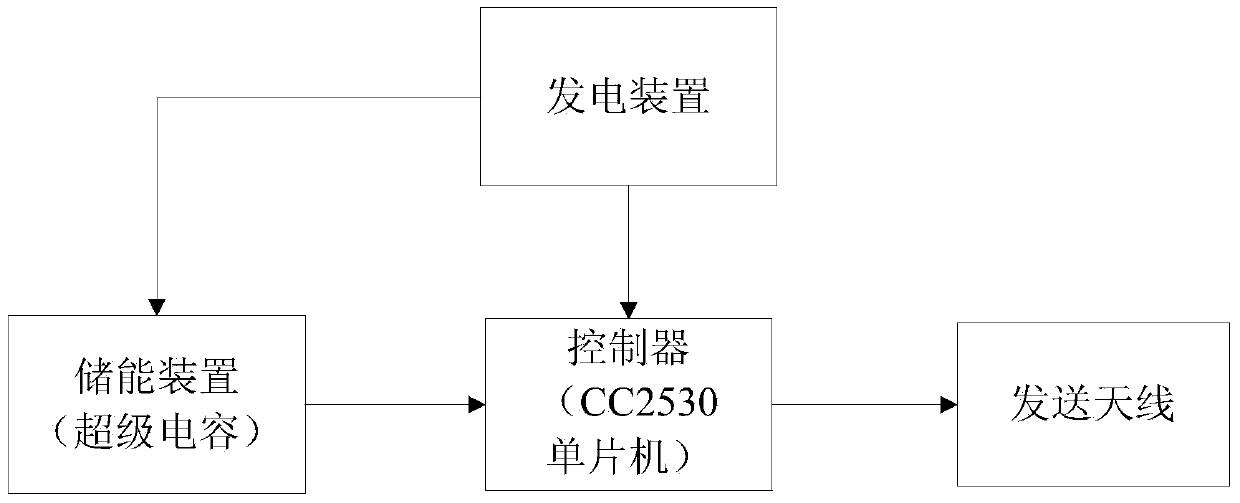

[0045] On the basis of the above embodiments, another temperature measuring device on the vibrating tank is provided in this embodiment, including a power generation device 1 and a temperature acquisition device 2. The power generation device 1 and the temperature acquisition device 2 in this embodiment are the same as those in the embodiment 1, that is, the power generation device 1 includes a generator, a rectification and filtering circuit, and a voltage stabilizing circuit, and the temperature acquisition device 2 includes a temperature sensor and a controller connected to the temperature sensor. In addition to the above structure, the temperature measuring device on the vibrating tank in this embodiment also includes an energy storage device, such as figure 2 As shown, the energy storage device is connected to the power generating device 1 and charged by the power generating device 1 . The energy storage device can also provide power for electrical components in the temp...

Embodiment 3

[0049] On the basis of Embodiment 1 and Embodiment 2, the temperature measuring device in this embodiment further includes a transmitting antenna at the collecting and transmitting end of the temperature signal, and the above-mentioned temperature collecting device 2 is connected to the transmitting antenna. The temperature acquisition device 2 collects the temperature of the position to be measured, and transmits the signal to the controller CC2530 single-chip microcomputer, and then converts the collected temperature signal through the CC2530 single-chip microcomputer, converts the analog signal into a digital signal, and then transmits the signal through the transmitting antenna .

[0050] The antenna here can be a commonly used signal antenna, or it can be a wireless signal transceiver device such as Bluetooth, wifi, Zigbee, etc. In addition, the signal can also be transmitted through a wired method, but limited by the workplace, the wireless method is more convenient. In ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com