A method for detecting surface defects of solid wood flooring based on image fusion and segmentation

A solid wood floor and defect detection technology, applied in image analysis, image data processing, instruments, etc., can solve problems such as slow segmentation speed, inaccurate segmentation, and low precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

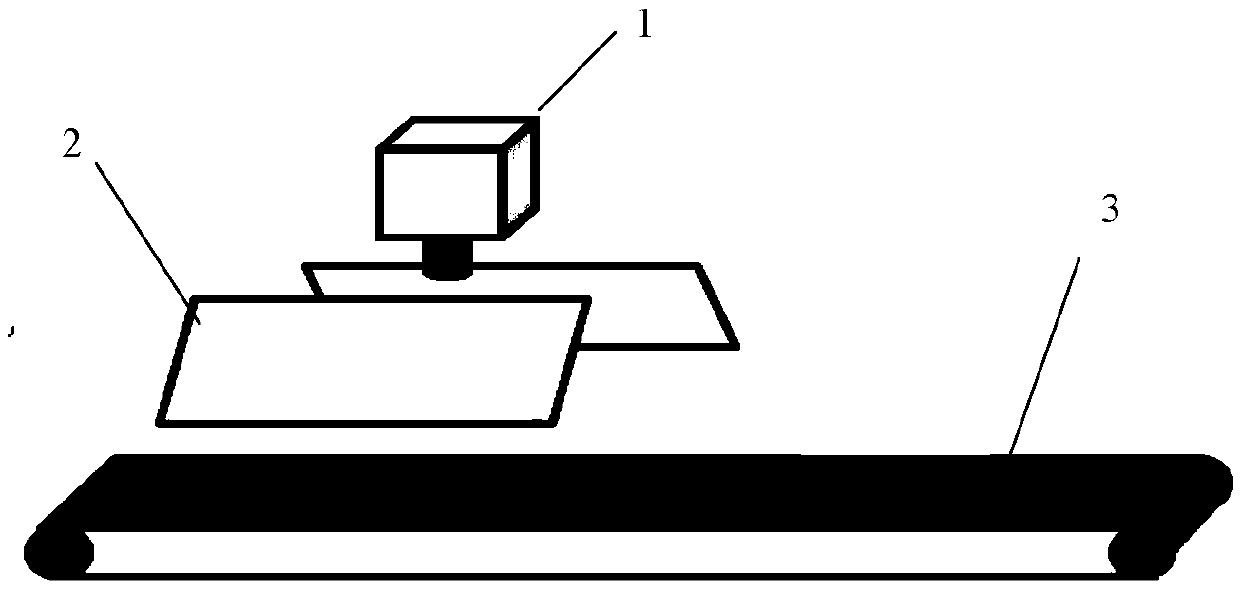

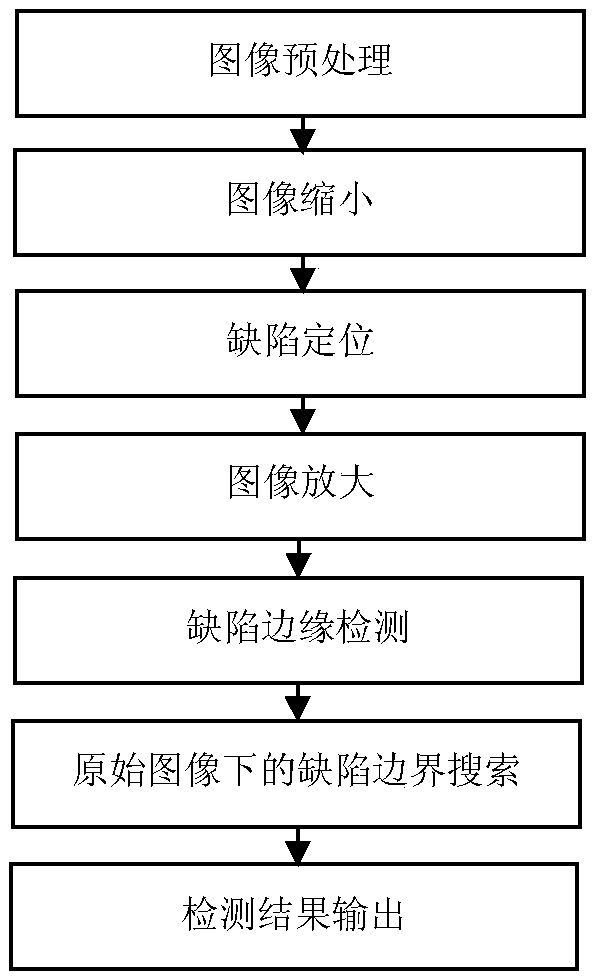

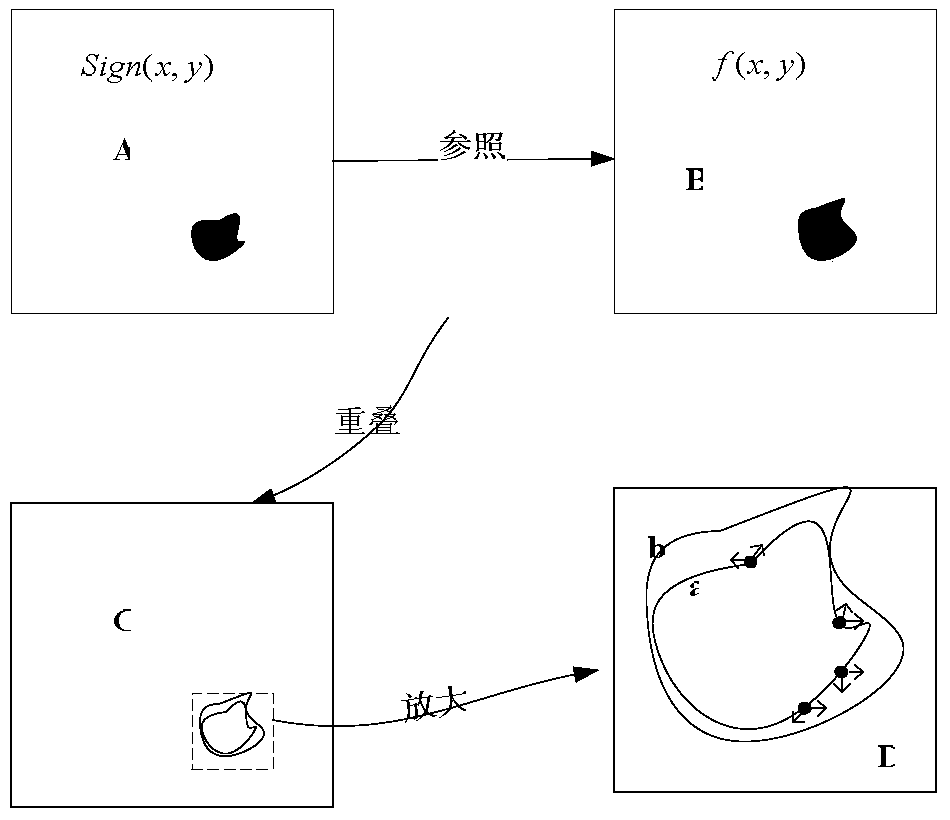

[0086] combine Figures 1 to 7 The inventive method is described in detail:

[0087] 1. About the sorting system that the present invention relates to the overview

[0088] The composition of computer vision system for defect detection of solid wood flooring is as follows: figure 1 shown. The system consists of a transmission platform, a CCD camera, a lens, a camera bracket, a light source system, an image acquisition card and defect detection software. The CCD camera is OscarF810CIRF from Germany; in order to improve the clarity of image collection, two LED parallel light sources are used to illuminate the inspection floor; the size of the collected floor image affects the image processing time and recognition effect, and the two are a pair of contradictions. Research shows that: Among the three types of images of 512×512, 256×256 and 128×128, 256×256 can not only guarantee the processing time but also effectively avoid the false recognition rate [12] , so the 256×256 sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com