Derating control method for permanent magnet synchronous motor

A technology of permanent magnet synchronous motor and control method, which is applied in the direction of speed/torque control of a single motor, and can solve problems such as system performance limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

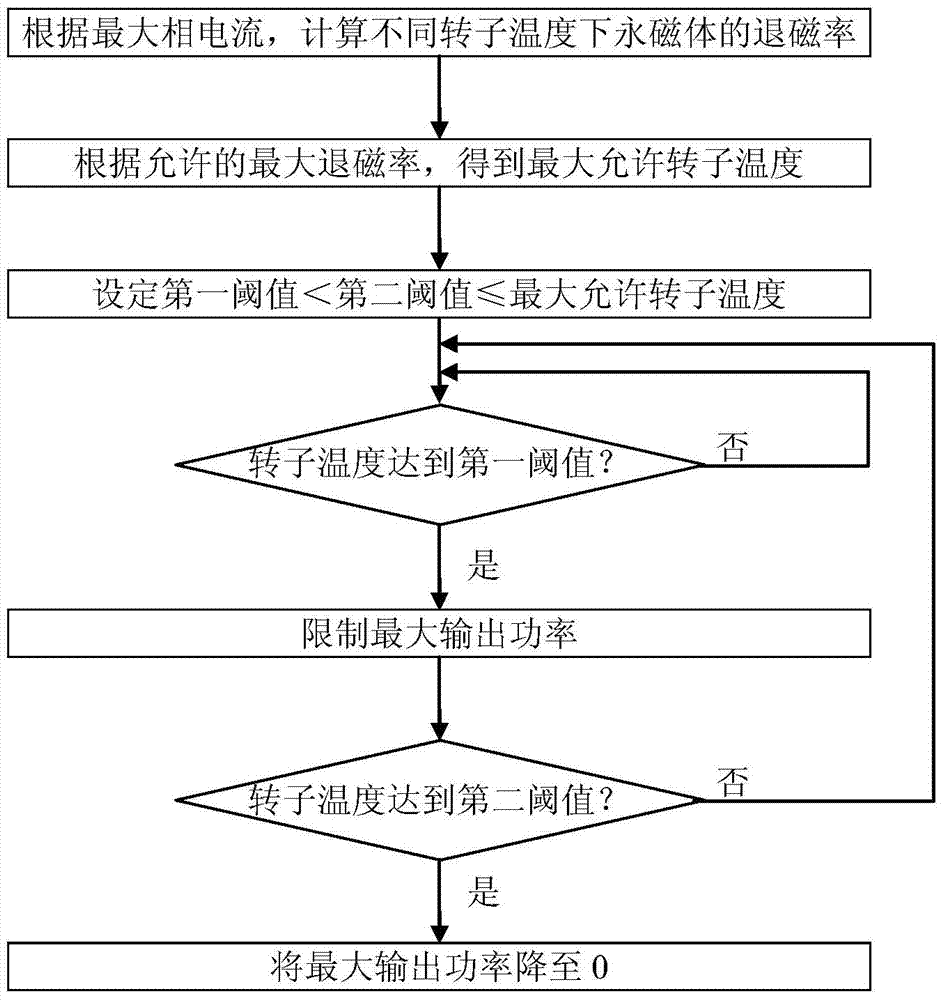

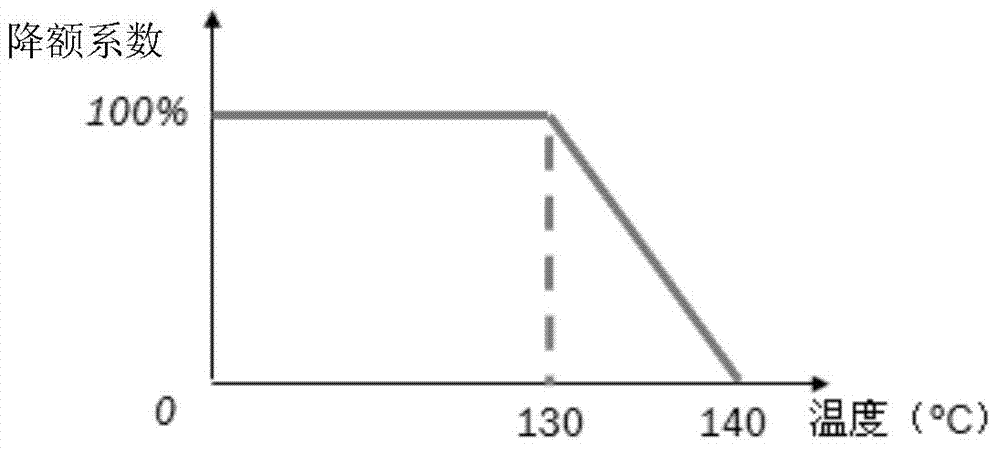

[0036] see Figure 5 , the derating control method of the permanent magnet synchronous motor of the present application comprises the following steps:

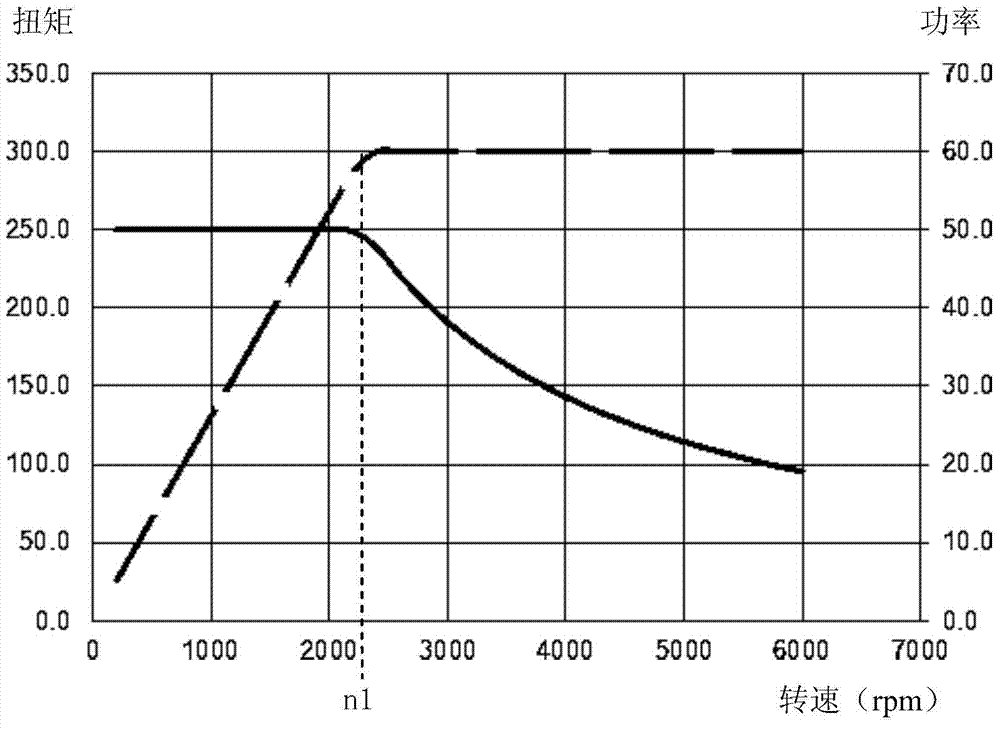

[0037] In the first step, the permanent magnet synchronous motor is simulated from the normal working mode to the failure response mode. Each simulation is based on the different output speed of the permanent magnet synchronous motor, but always maintains the maximum output torque under the speed condition. Record the instantaneous peak current at each rotational speed.

[0038] This kind of simulation can be a transient current simulation in the form of software, which is carried out on the circuit model of the built motor drive system, mainly to simulate the transient change of the three-phase current of the motor when the mode is switched; it can also be a simulation of the actual motor drive system test measurement. see Figure 6, when the permanent magnet synchronous motor switches from the normal working mode (such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com