Bulletproof fabric and method for producing the same

A technology of bulletproof fabrics and fabrics, applied in the direction of fabrics, woven fabrics, protective equipment, etc., can solve problems such as user injuries, and achieve the effect of preventing injuries and excellent bulletproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

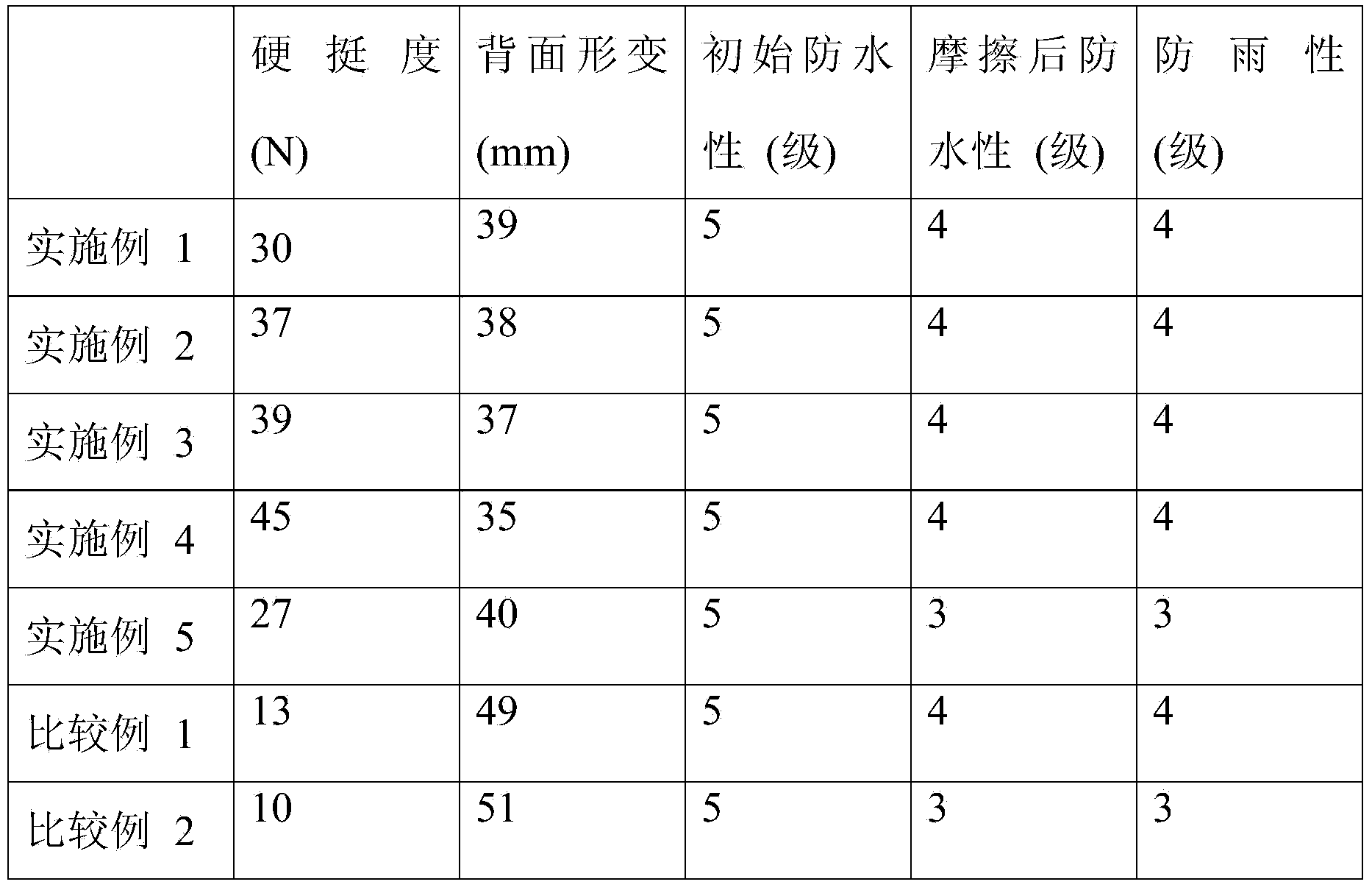

Examples

Embodiment 1

[0060] The fabric was woven into a plain weave using peraramid multifilaments comprising peraramid monofilaments having a fineness of 1.0 as warp and weft. Warp density and weft density are 10pcs / cm. Next, at about 60 °C with Na 2 CO 3 The fabric is treated with a scouring agent, then washed with water and dried.

[0061] Next, the scoured fabric is dipped in a water repellant, which saturates the fabric. The water repellent comprises 3% by weight of hydroxylated perfluoroalkyl ethyl acrylate copolymer, 3% by weight of polyethylene terephthalate, 3% by weight of toluene diisocyanate, 0.3% by weight of dipropylene glycol , 0.3% by weight of maleic acid, 0.3% by weight of maleic acid and 90.1% by weight of water.

[0062] The fabric impregnated with the water repellent was heat-treated at a temperature of about 160° C. for 60 seconds to obtain a bulletproof fabric.

Embodiment 2

[0064] A bulletproof fabric was prepared in the same manner as described in Example 1, except that a water repellent containing the same content of polyacrylate resin was used instead of polyethylene terephthalate.

Embodiment 3

[0066] A bulletproof fabric was prepared in the same manner as described in Example 1, except that a water repellent containing the same content of melamine resin was used instead of polyethylene terephthalate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com