Protective garment used for electric welding for leak repairing of oil well pipeline

A technology of protective clothing and pipelines, applied in the field of protective clothing, can solve the problems of easy burns, small scope, and large construction danger, and achieve the effect of avoiding direct access to the mask, ensuring sealing, and flexible use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to clearly illustrate the technical features of the solution of the present invention, the present invention will be described below in conjunction with specific embodiments and accompanying drawings.

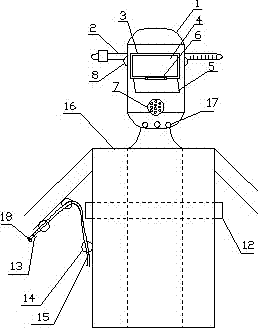

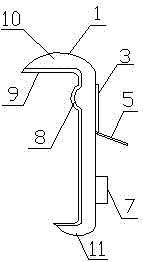

[0014] Depend on figure 1 , 2 It can be seen that a kind of protective clothing for oil well pipeline electric welding leakage repair, the protective clothing includes electric welding protective mask 1, asbestos anti-penetration protective clothing 16, wherein electric welding protective mask 1 includes goggles, fastening belt 2, electric welding protective mask 1 and asbestos anti-penetration The protective clothing 16 is connected by a buckle 17. It is characterized in that the goggles are composed of a dark goggle lens 5 and a light-colored filmed lens 4, and the light-colored filmed lens 4 is fixed in the mask goggle frame 3. The lower end of color-added film lens 4 is provided with rotating shaft 6, and rotating shaft 6 connects dark-colored goggle lens 5...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap