Capsule production system and control method thereof

A technology of a capsule production system and control method, which is applied in the directions of capsule delivery, pharmaceutical formulation, and drug delivery, can solve the problems of high failure rate, high labor intensity, and inability to meet the quality of capsule molding, and achieve high thermal efficiency, improve quality, and eliminate the need for Effect of mechanical action hysteresis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

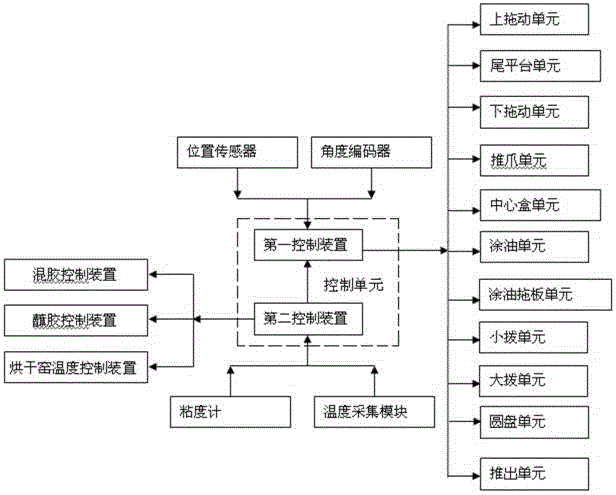

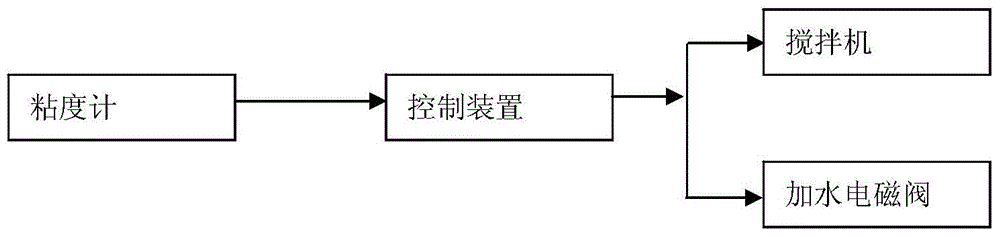

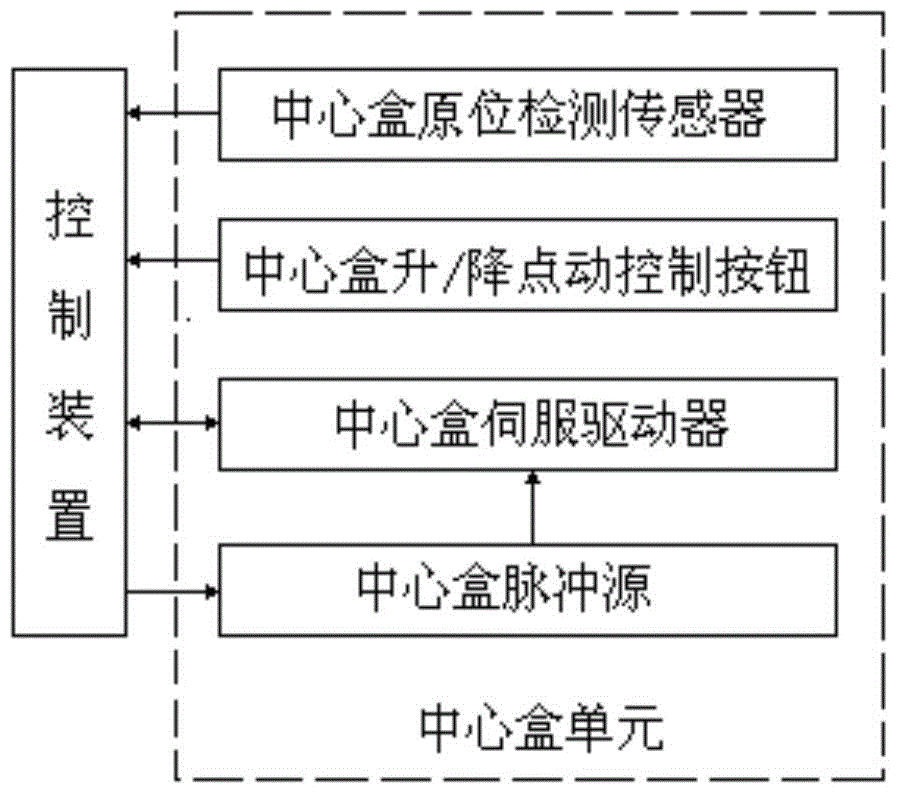

[0080] Such as figure 1 As shown, the capsule production system of the present invention includes a control unit, a motion control part and a process control part, wherein the motion control part has an upper drag unit, a tail platform unit, a lower drag unit, a push claw unit, a center box unit, an oiled Unit, oiling carriage unit, small pulling unit, large pulling unit, disc unit and glue dipping control unit, the input of the control unit is connected with the signal collected by the position sensor and angle encoder, and the output terminal outputs the corresponding control command to The corresponding units in the above-mentioned motion control part; the process control part has a rubber mixing control device, a glue dipping control device and a drying kiln control device. Command to the corresponding device in the process control section above.

[0081] The main function of the capsule production system of the present invention is to provide power and heating for the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com