A method and system for harmless treatment of waste plate catalysts

A technology of harmless treatment and treatment system, which is applied in the field of harmless treatment method and treatment system of waste plate catalysts, can solve the problems of reduced catalyst activity, thermal aging of catalyst, shortened lifespan, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

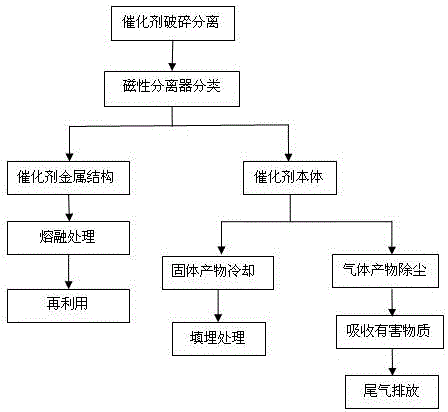

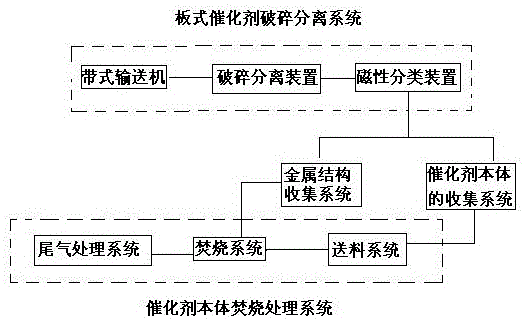

[0029] A harmless treatment system for waste plate catalysts, including a plate catalyst crushing and separation system and a catalyst body incineration treatment system. The plate catalyst crushing and separation system includes sequentially connected belt conveyors, crushing and separating devices and magnetic classification devices. The lower end of the sorting device is also equipped with a collection system to collect the catalyst metal structure and the catalyst body respectively; the separated metal structure is sent to the melting furnace, heated to above 1500°C and melted for reuse.

[0030] The catalyst body incineration treatment system includes a feeding system, an incineration system and a tail gas treatment system connected in sequence.

[0031] The incineration treatment system is an incinerator, the incineration furnace chamber is a hollow geometry, and the inner wall is provided with a refractory layer.

[0032] The tail gas treatment system includes a dust co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com