Body structure of full-bearing coach

A full load-bearing technology for large buses, applied in load-bearing body structures, upper structures of passenger cars, superstructures, etc., can solve problems such as poor safety of large passenger vehicle rollover structures, low utilization of vehicle interior space, and restrictions on the development of conventional passenger vehicles, etc. , achieve good indoor air quality, single body skeleton structure, and improve consistency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

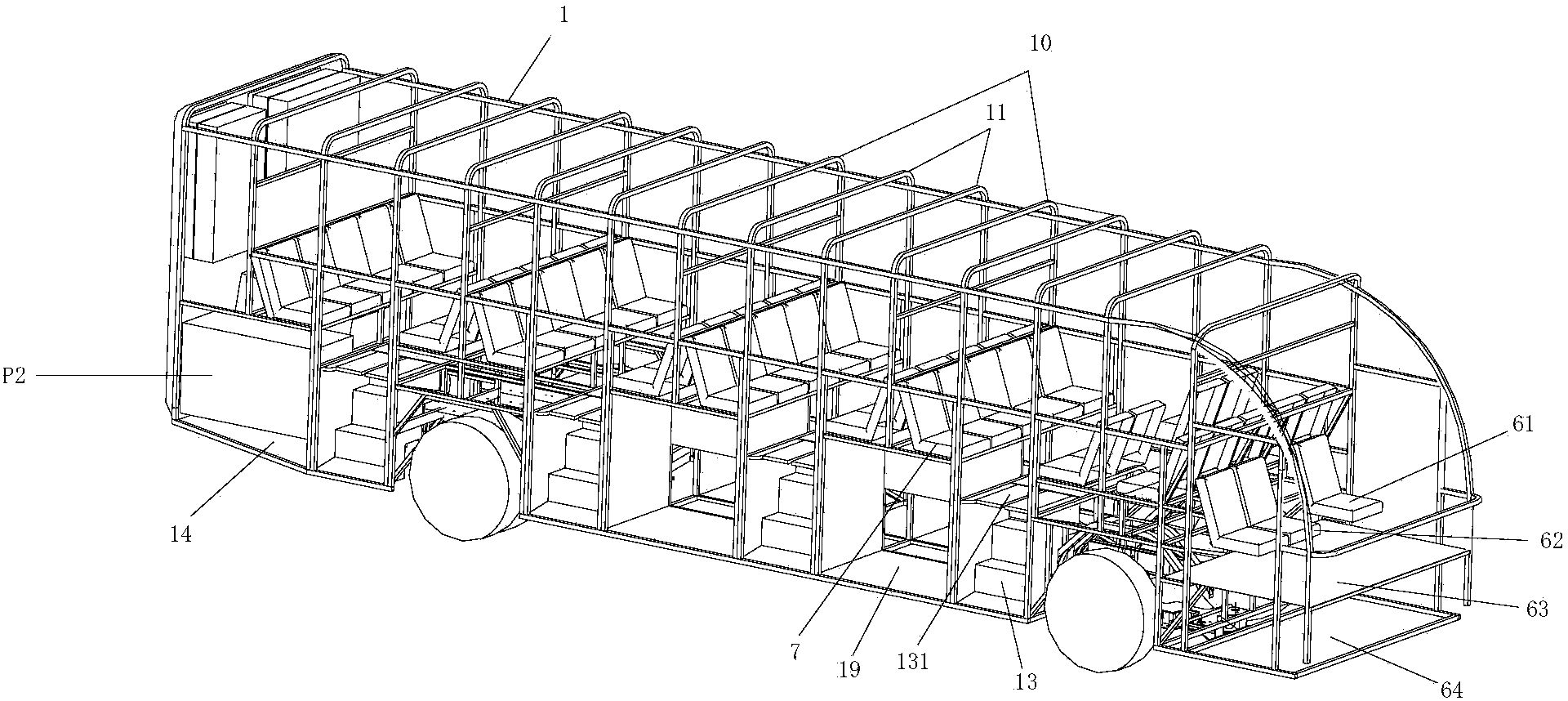

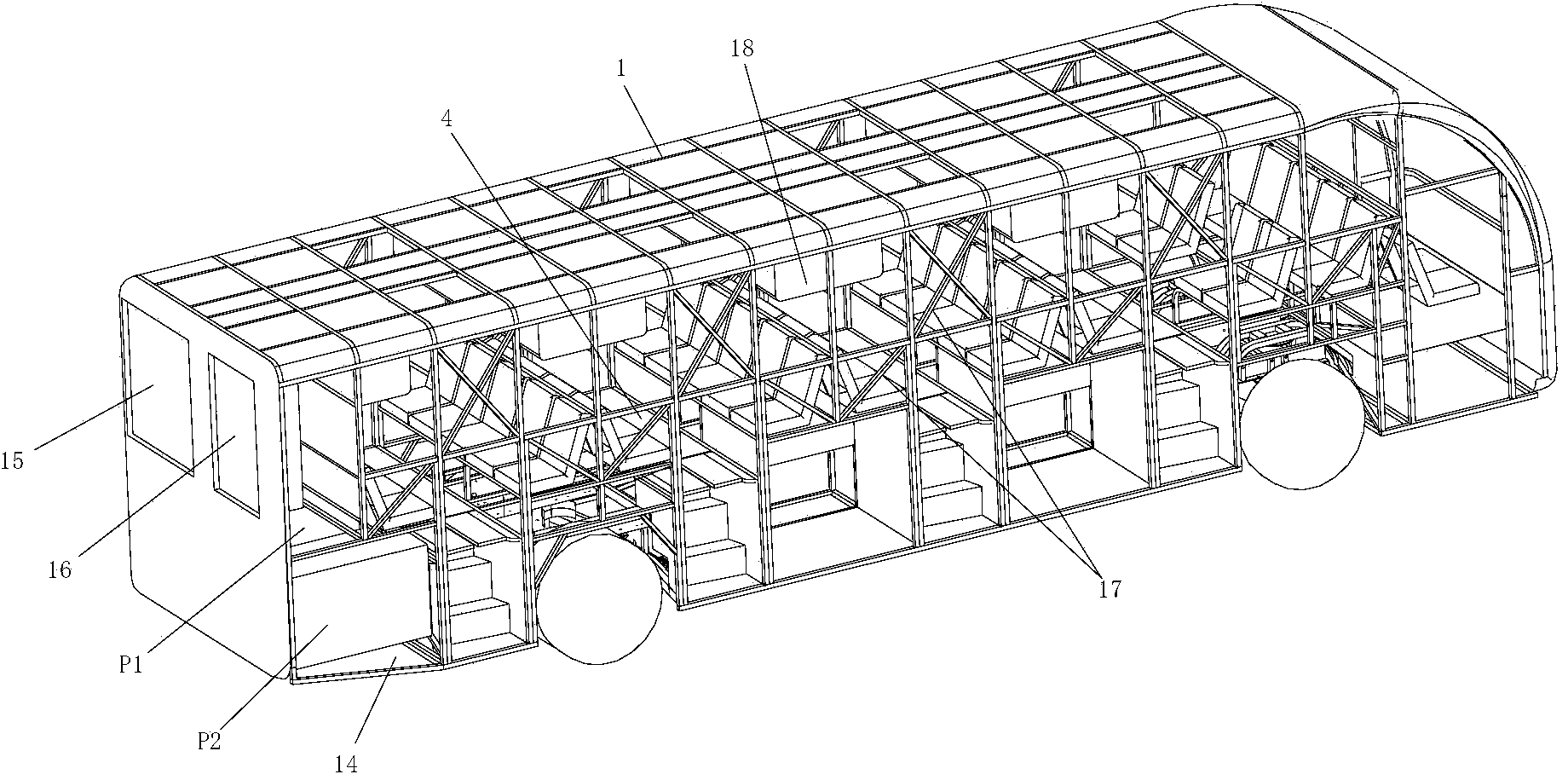

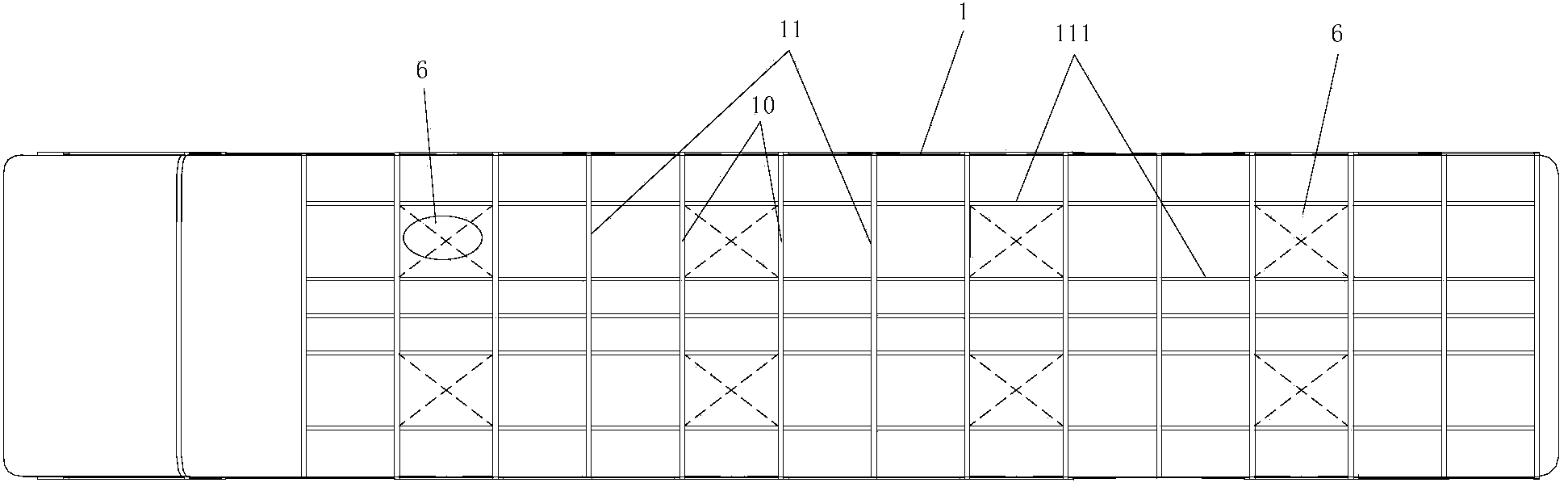

[0029] see Figure 1~3 , the present embodiment is provided with skeleton 1, top cover (short drawing), side panel (short drawing), floor 4, window (short drawing), safety sunroof 6 and seat. The top cover is set on the top of the frame 1, the side panel is set on the periphery of the frame 1, the floor 4 is set on the bottom of the frame 1, the window is set on the side of the frame, and the safety skylight 6 is set on the top of the frame 1 (8 pieces). The skeleton 1 is an integral frame structure, and the skeleton 1 is provided with transverse ring frames 10 and 11 spaced along the longitudinal direction, including the transverse ring frame 10 not extending to the bottom and the transverse ring frame 11 extending to the bottom. An independent passenger area is formed between every 2 horizontal ring frames 10 and 2 horizontal ring frames 11 and the top cover and the floor, and the seats 7 in each passenger area are horizontally arranged in 2 rows and facing each other. Hori...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com