Reclaiming and purifying circulation environment-friendly system and reclaiming and purifying method for waste residues and wastewater of mines

A waste water recycling, purification and recycling technology, applied in mining waste water treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

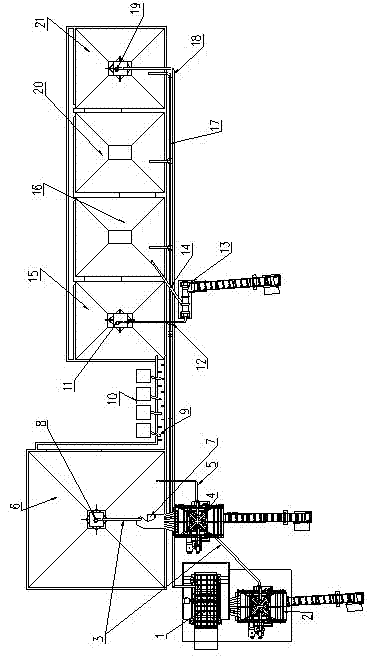

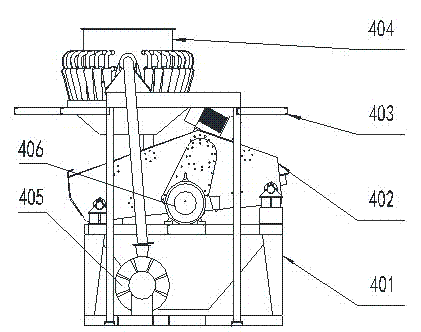

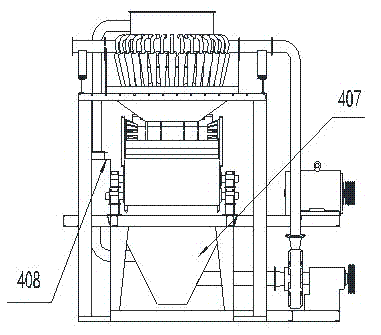

[0012] Embodiment 1: with reference to attached Figure 1-4 . An environmental protection system for recovery, purification, recycling and environmental protection of mine waste slag waste water, the outlet of vibrating screen 1 is directly connected to the inlet of the primary sand-water separation system 2, and the water outlet of the water tank of the primary sand-water separation system 2 is directly connected to the superfine mud-sand water separation system 4 through the water delivery pipe 3 On the surface, the end of the water tank in the ultra-fine mud-sand water separation system 4 is provided with an overflow tank 7, and the outlet of the overflow tank 7 is directly connected to the inlet of the primary separation tank 6, and the sewage outlet of the ultra-fine mud-sand water separation system 4 passes through the water pipeline 5. For the primary separation tank 6, the precipitated sand, water, and mud mixture of the primary separation tank 6 are sent to the screen...

Embodiment 2

[0022] Embodiment 2: On the basis of Embodiment 1, the overflow port of the third-stage sedimentation tank 16 is connected with the entrance of the fourth-stage sedimentation tank 20, the overflow port of the fourth-stage sedimentation tank 20 is connected with the entrance of the fifth-stage sedimentation tank 21, and the water pump 19 is located at In the five-stage sedimentation tank 21 and through the return pipe 18, the purified water is transported to the vibrating screen 1 for recycling.

Embodiment 3

[0023] Embodiment 3: On the basis of Embodiment 1, the muddy water separated by the ultrafine mud sand water separation system 4 is sent to the horizontal centrifuge 13 through the delivery pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com