Aluminum oxide/zirconium oxide SLM (selective laser melting) ceramic powder material and preparation method thereof

A technology for powder materials and ceramic blocks, applied in the field of alumina/zirconia SLM ceramic powder materials and their preparation, can solve the problems of component segregation, cracking of molded parts, insufficient mechanical properties of molded ceramic parts, etc. good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

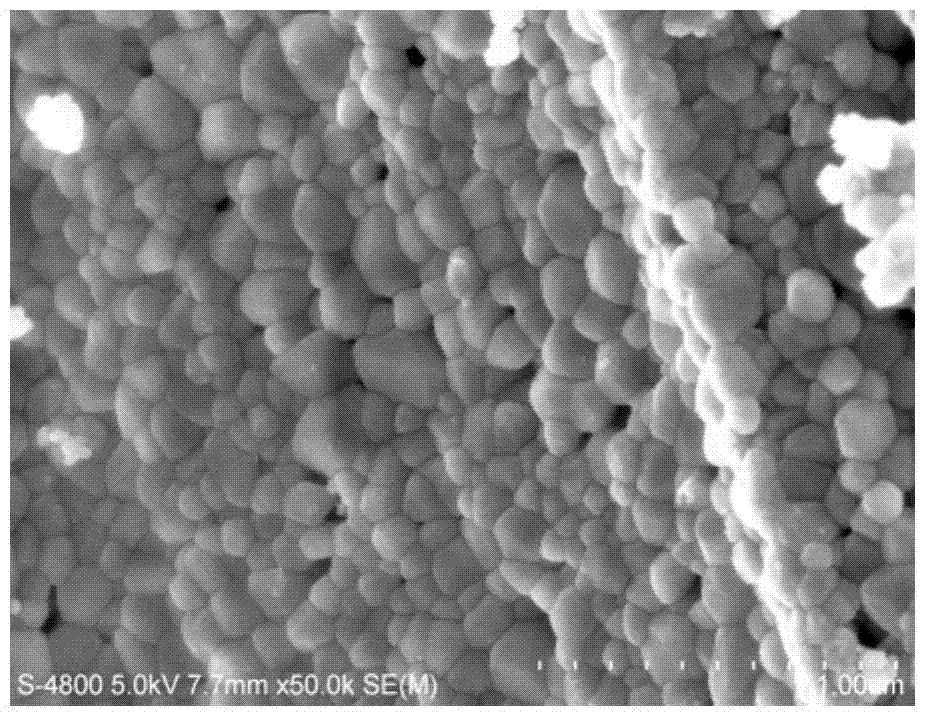

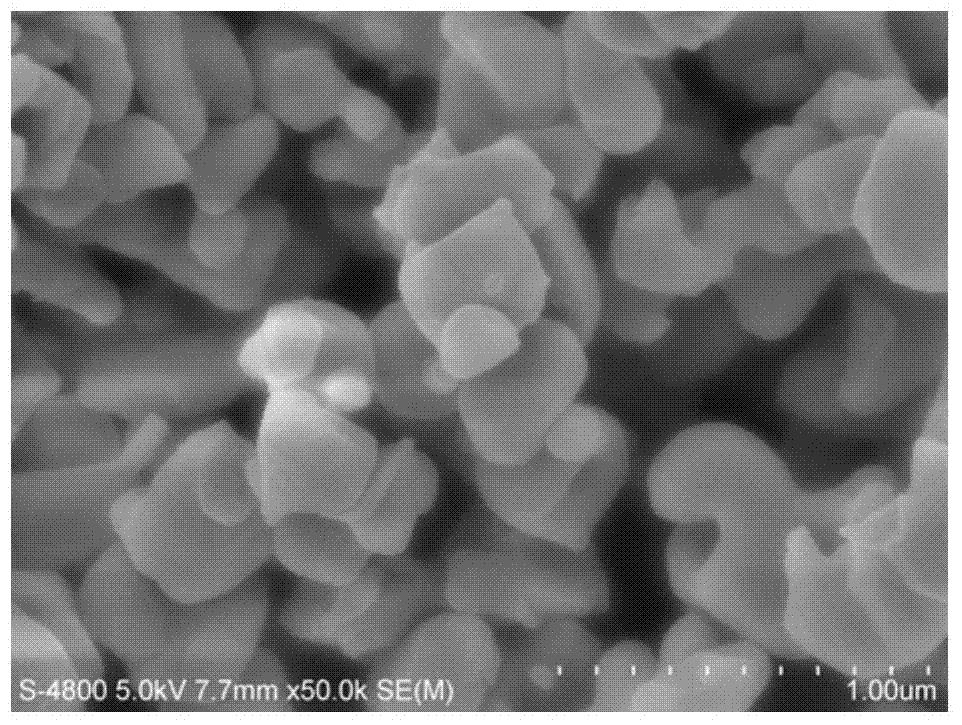

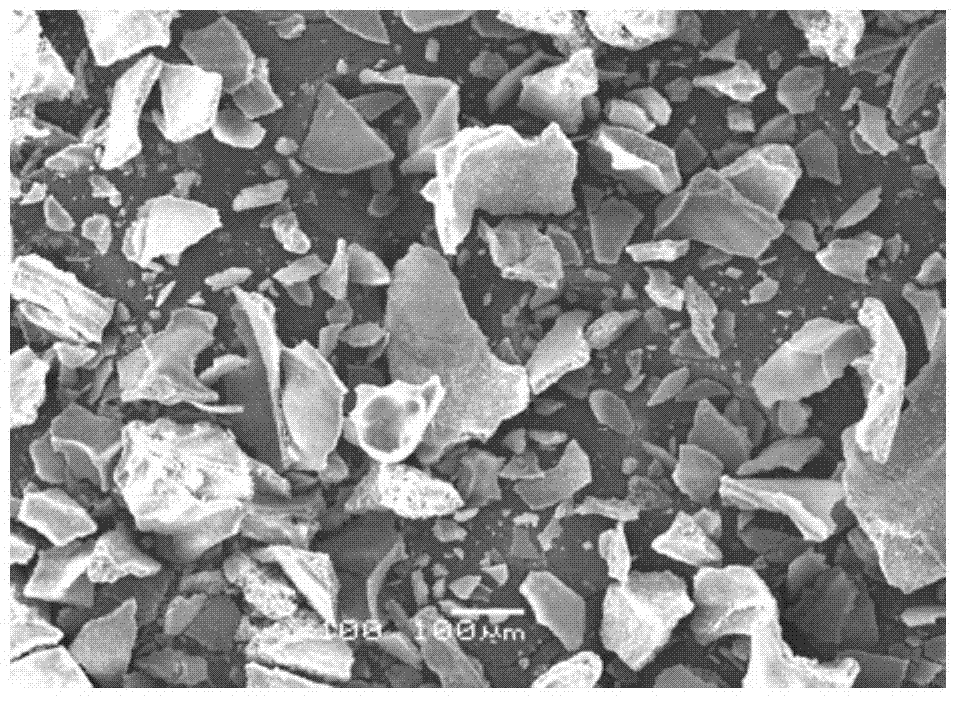

[0032] This embodiment provides a kind of Al that is used for SLM preparation molding 2 o 3 / ZrO 2 Powder material, with Al 2 o 3 and ZrO 2 Powder is raw material, prepared according to mass percentage, Al 2 o 3 Powder accounted for 62.5wt%, ZrO 2 Powder accounted for 37.5wt%, of which ZrO 2 The powder contains 2wt% Y 2 o 3 Stabilizer, the prepared Al 2 o 3 / ZrO 2 The particle size of the powder material D50 is less than 100 μm.

[0033] Will Al 2 o 3 / ZrO 2 The powder material is processed into an SLM ceramic block on the SLM equipment, and each layer is first preheated by the same method, and then clad and clad.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com