Biodegradable screw air compressor oil

An air compressor oil and biodegradation technology, applied in the field of lubricating oil, can solve the problems of thermal oxidation stability, poor low temperature fluidity, etc., and achieve the effects of improving oxidation stability, reducing double bond content and being environmentally friendly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

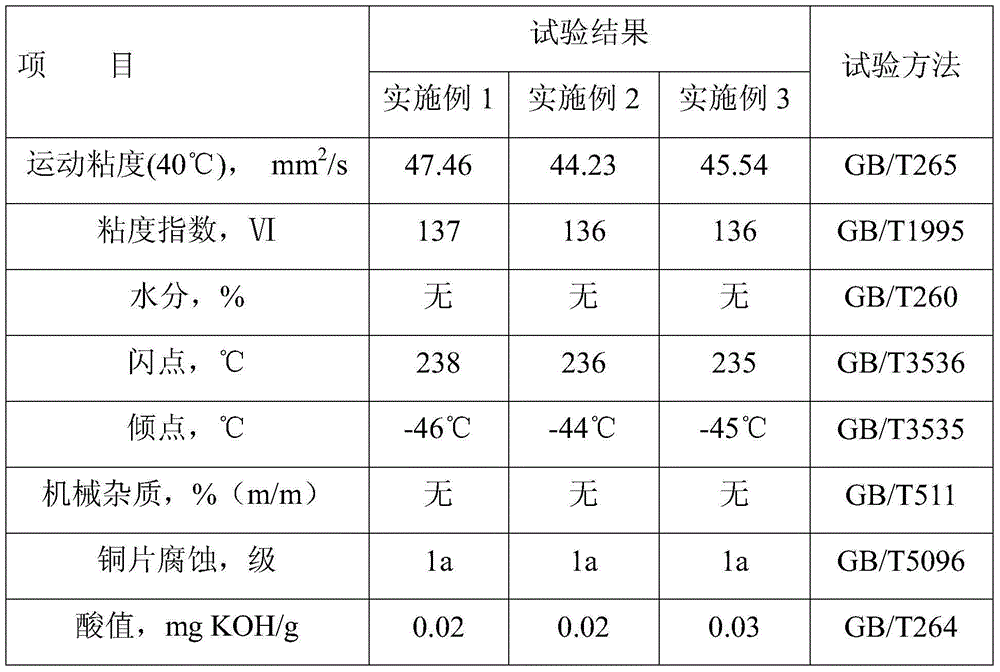

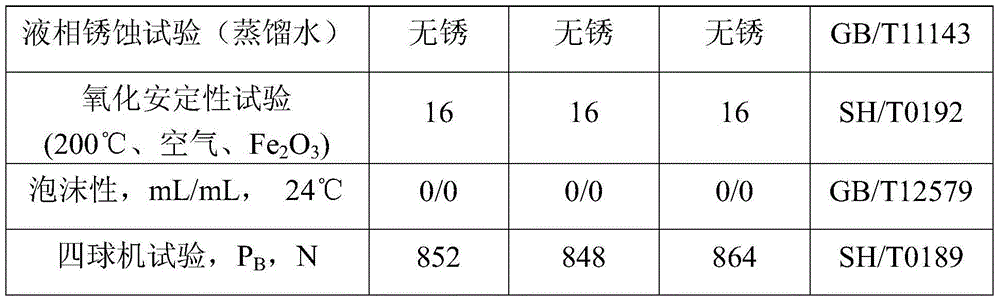

Embodiment 1

[0015] Take 46 parts of base oil A and 51.64 parts of PAG polyether base oil into a stainless steel blending kettle with agitator, keep the temperature of the kettle at 60°C, and stir continuously for 0.5 hours; sequentially add 0.5 parts of alkylated diphenylamine, 0.9 parts Add borate ester anti-oxidant and anti-wear agent, 0.4 part of high-temperature ashless anti-wear agent; 0.5 part of sorbitol fatty acid ester; 0.05 part of benzotriazole derivative; 0.01 part of copolymer of acrylate and ether into the blending kettle , maintain the temperature of the kettle at 65°C, and continue to stir for 1 hour until the mixture is completely dissolved and uniform, and the refined oil is obtained.

Embodiment 2

[0017] Take 48.3 parts of base oil B and 48.79 parts of polyether base oil into a stainless steel mixing tank with agitator for reaction, keep the temperature of the tank at 60°C, and continue stirring for 0.5 hours; sequentially add 0.4 parts of alkylated diphenylamine, 0.6 parts Borate antioxidant, 0.6 part of high temperature ashless anti-wear agent; 0.8 part of sorbitol fatty acid ester; 0.5 part of polyalphaolefin pour point depressant; The temperature was 65°C, and the mixture was continuously stirred for 1 hour until the mixture was completely dissolved and became uniform, and the refined oil was obtained.

Embodiment 3

[0019] Take 28.5 parts of base oil A, 36 parts of base oil B, and 31.99 parts of PAG polyether base oil into a stainless steel mixing tank with agitator for reaction, keep the temperature of the tank at 60°C, and continue stirring for 0.5 hours; Alkylated diphenylamine, 0.75 parts of borate antioxidant, 0.8 part of high temperature ashless anti-wear agent; 0.95 part of sorbitol fatty acid ester; 0.5 part of polyalphaolefin pour point depressant; 0.01 part of copolymer of acrylate and ether Put it into the blending kettle, keep the temperature of the kettle at 60°C, and stir continuously for 1 hour, until the mixture is completely dissolved and becomes uniform, and the refined oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com