Liquid optical clear adhesive with low solidification energy and preparation method thereof

An optically transparent adhesive and liquid technology, applied in the field of light-curing materials, can solve the problems of large light refraction loss, high curing energy, and large energy consumption, and achieve the effects of improving contrast and clarity, speeding up production efficiency, and reducing refraction loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

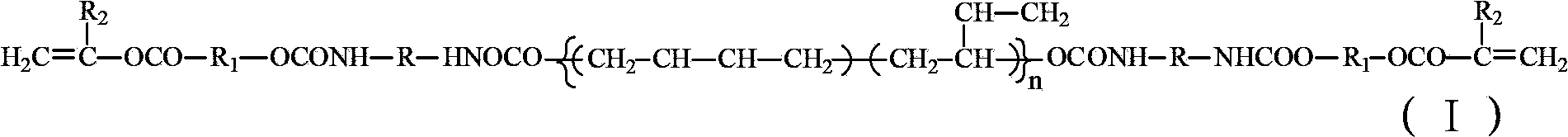

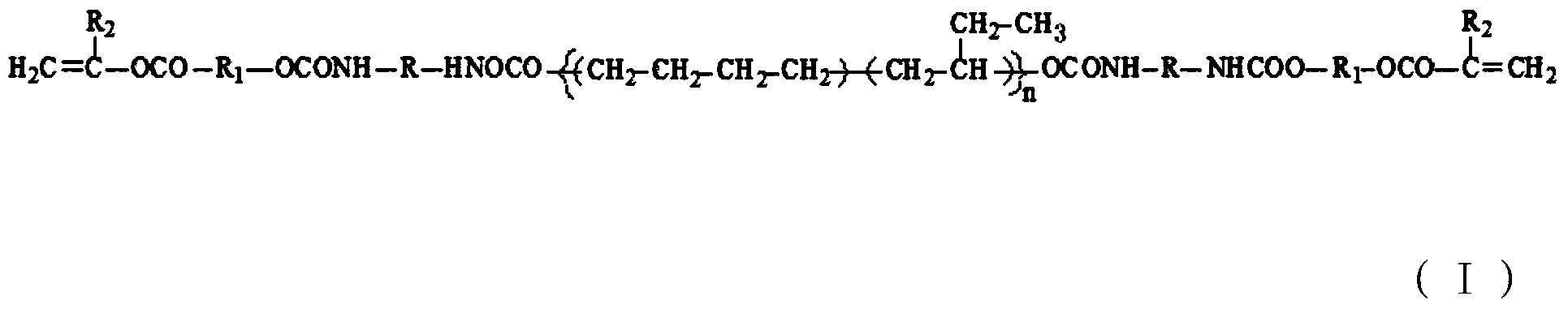

[0029] Accurately weigh 30g of hydrogenated polybutadiene urethane acrylate (as shown in the general formula (I), R represents the part of the molecular structure of 1,6-hexamethylene diisocyanate that does not contain isocyanate groups; R 1 Representative-C 3 h 6 -; R 2 Representative-H), 40g liquid polybutadiene resin (Polyoil 110), 30g isooctyl acrylate, 2.5g n-dodecyl mercaptan, 4g photoinitiator 184, 0.2g light stabilizer 770, the above groups Add it to the blender one by one, mix evenly, vacuumize and defoam (vacuum degree -0.1MPa, 0.1h), let it stand naturally to room temperature, and seal the package.

Embodiment 2

[0031] Accurately weigh 28g of hydrogenated polybutadiene-type urethane acrylate (as shown in general formula (I), R represents the part that does not contain isocyanate groups in the molecular structure of isophorone diisocyanate; R 1 Representative-C 3 h 6 -; R 2 Represent-CH 3 ), 60g liquid polybutadiene resin (Polyoil 130), 15g isobornyl acrylate, 1g trimethylolpropane tris(3-mercaptopropionate), 2g photoinitiator BP, 1g photoinitiator TPO, 0.6g For light stabilizer 622, add the above components into the mixer in turn, mix evenly, vacuumize and degas (vacuum degree -0.09MPa, 0.2h), let it stand naturally to room temperature, and seal the package.

Embodiment 3

[0033] Accurately weigh 16g of hydrogenated polybutadiene polyurethane acrylate (as shown in the general formula (I), R represents the part that does not contain isocyanate groups in the molecular structure of methylcyclohexyl diisocyanate; R 1 Representative-C 4 h 8 -; R 2 Represent-CH 3 ), 60g liquid polybutadiene resin (Polyoil 130), 20g isobornyl methacrylate, 5g trimethylolpropane tris (3-mercaptopropionate), 4g photoinitiator 1173, 1g photoinitiator TEPO, 0.2g of light stabilizer 292, add the above components into a double planetary power mixer in turn, mix evenly, after vacuuming and defoaming (vacuum degree -0.08MPa, 0.3h), let it stand naturally to room temperature, and seal the package, that is have to.

PUM

| Property | Measurement | Unit |

|---|---|---|

| curing dosage | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com