Dynamic cross-linked type weather-resistant ABS (Acrylonitrile Butadiene Styrene) edge band material and preparation method thereof

A dynamic cross-linking and edge-sealing technology, applied in the field of plastics, can solve the problems of poor weather resistance of ABS resin, easy to be attacked by light and oxygen, and affect the service life, achieve dimensional stability, and eliminate the risk of being attacked by light and oxygen. , The effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

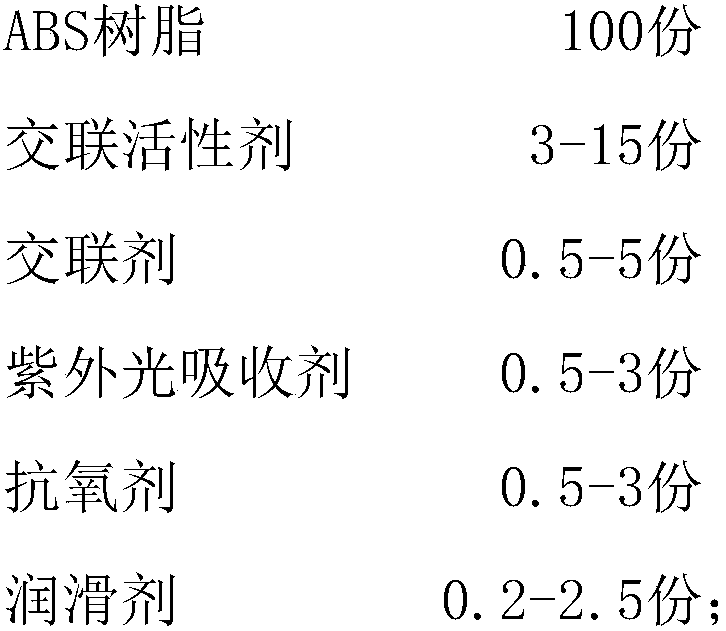

[0046] A dynamically cross-linked weather-resistant ABS edge strip material, comprising the following raw materials in parts by weight:

[0047]

[0048] Wherein, the crosslinking agent is an organic sulfur compound.

[0049] Preferably, the melt flow rate of the ABS resin is 45g / min, and the mass percentage of polybutadiene is 22%.

[0050] Preferably, the cross-linking active agent is compounded by nanometer zinc oxide and stearic acid in a mass ratio of 9:1.

[0051] Preferably, the crosslinking agent is tetramethylthiuram disulfide.

[0052] Preferably, the ultraviolet absorber is 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-chlorinated benzotriazole and tris(1,2,2,6, 6-pentamethylpiperidinyl) phosphite is compounded according to the weight ratio of 2:1.

[0053] Preferably, the antioxidant is tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and dioctadecyl thiodipropionate according to weight ratio It is compounded at 3:2.

[0054] Pre...

Embodiment 2

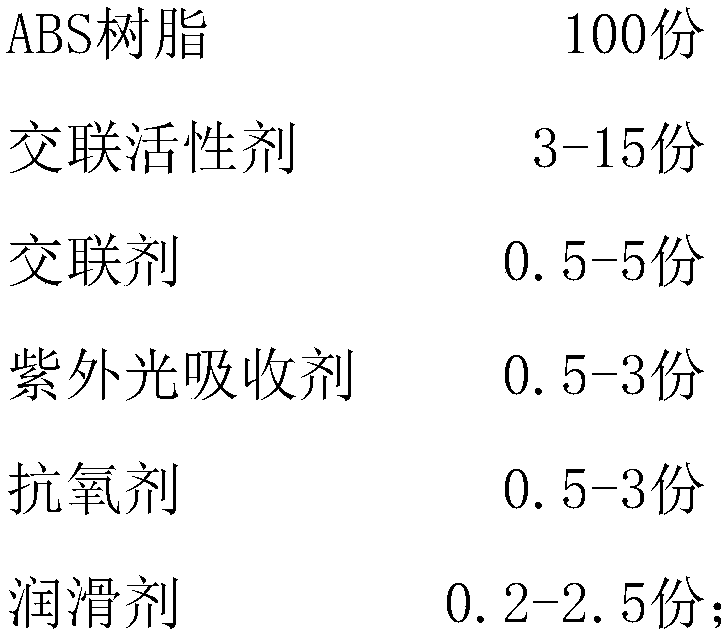

[0061] A dynamically cross-linked weather-resistant ABS edge strip material, comprising the following raw materials in parts by weight:

[0062]

[0063]

[0064] Wherein, the crosslinking agent is an organic sulfur compound.

[0065] Preferably, the melt flow rate of the ABS resin is 48g / min, and the mass percentage of polybutadiene is 24%.

[0066] Preferably, the cross-linking active agent is compounded by nanometer zinc oxide and stearic acid in a mass ratio of 8:1.

[0067] Preferably, the crosslinking agent is tetraethylthiuram disulfide.

[0068] Preferably, the ultraviolet absorber is 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-chlorinated benzotriazole and tris(1,2,2,6, 6-pentamethylpiperidinyl) phosphite is compounded according to the weight ratio of 1:1.

[0069] Preferably, the antioxidant is tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and dioctadecyl thiodipropionate according to weight ratio It is compounded at 1:2.

...

Embodiment 3

[0077] A dynamically cross-linked weather-resistant ABS edge strip material, comprising the following raw materials in parts by weight:

[0078]

[0079] Wherein, the crosslinking agent is an organic sulfur compound.

[0080] Preferably, the melt flow rate of the ABS resin is 50 g / min, and the mass percentage of polybutadiene is 25%. .

[0081] Preferably, the cross-linking active agent is compounded by nanometer zinc oxide and stearic acid in a mass ratio of 5:1.

[0082] Preferably, the cross-linking agent is dimorpholine tetrasulfide.

[0083] Preferably, the ultraviolet absorber is 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-chlorinated benzotriazole and tris(1,2,2,6, 6-pentamethylpiperidinyl) phosphite is compounded according to the weight ratio of 3:1.

[0084] Preferably, the antioxidant is tetrakis [β-(3,5-tertiary butyl-4-hydroxyphenyl) propionate] pentaerythritol ester and dioctadecyl thiodipropionate according to weight ratio It is compounded at 5:2.

[0085] P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com