Sputter coating method

A technology of sputtering coating and sputtering chamber, applied in the field of sputtering coating, which can solve the problems of obvious product edge effect and high risk of product rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

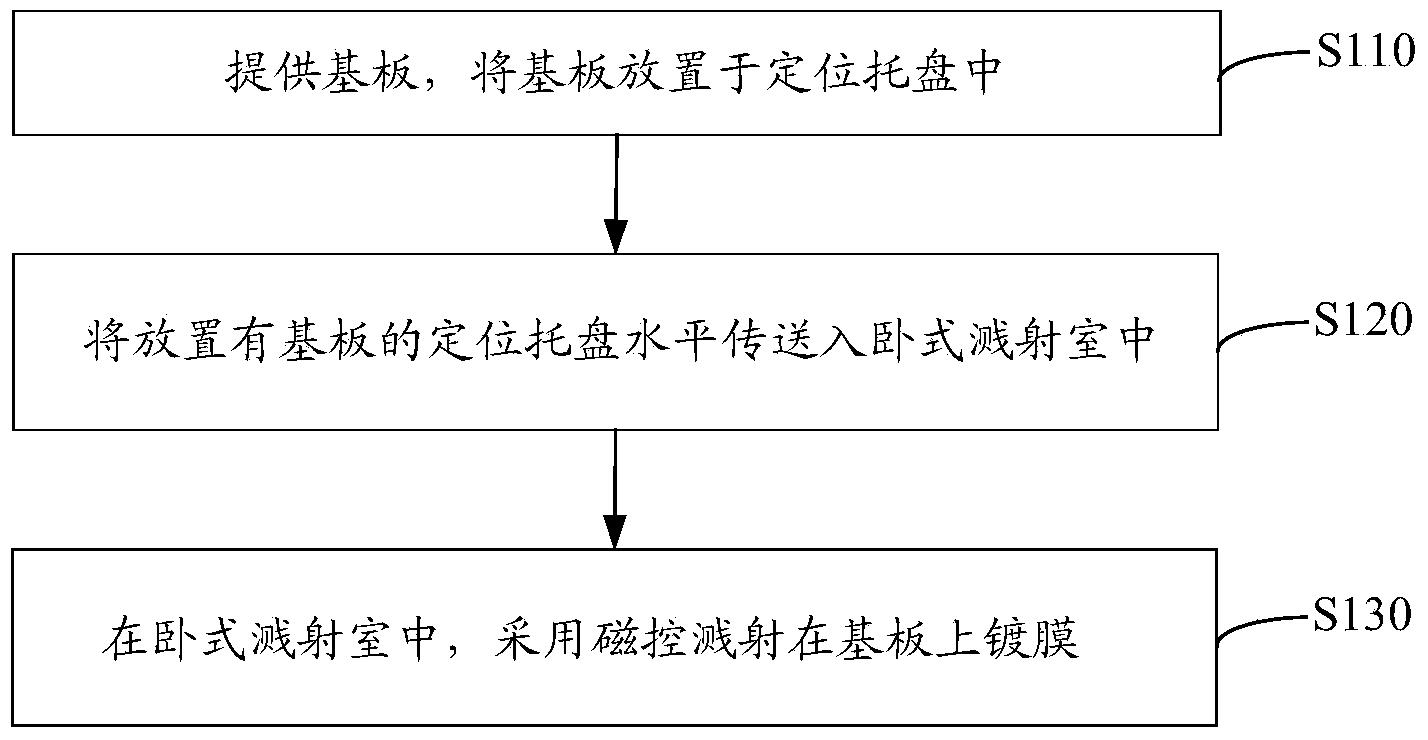

Method used

Image

Examples

Embodiment 1

[0061] 1. Provide TFT substrates, clean the TFT substrates with pure water and lye in turn with a cleaning machine, then perform two-fluid spraying, pure water spraying and high-pressure spraying in sequence, and then dry them with cold air and hot air in sequence, and set them aside; , the pressure of high pressure spraying is 1.2kg / cm 2 ;

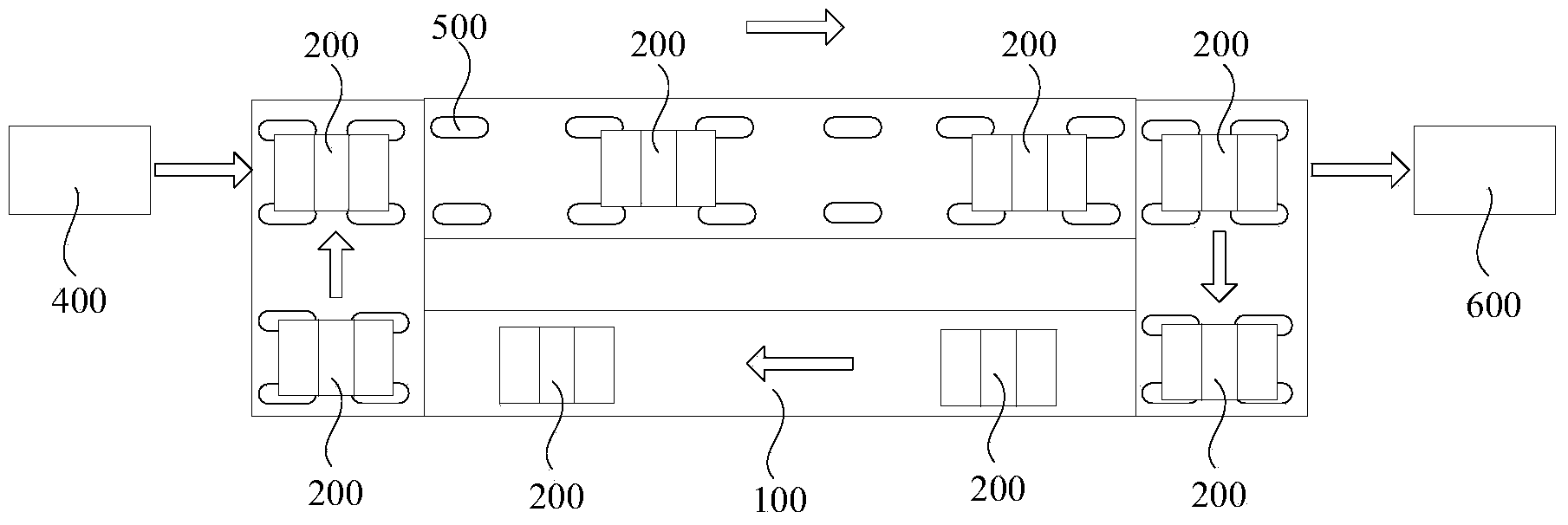

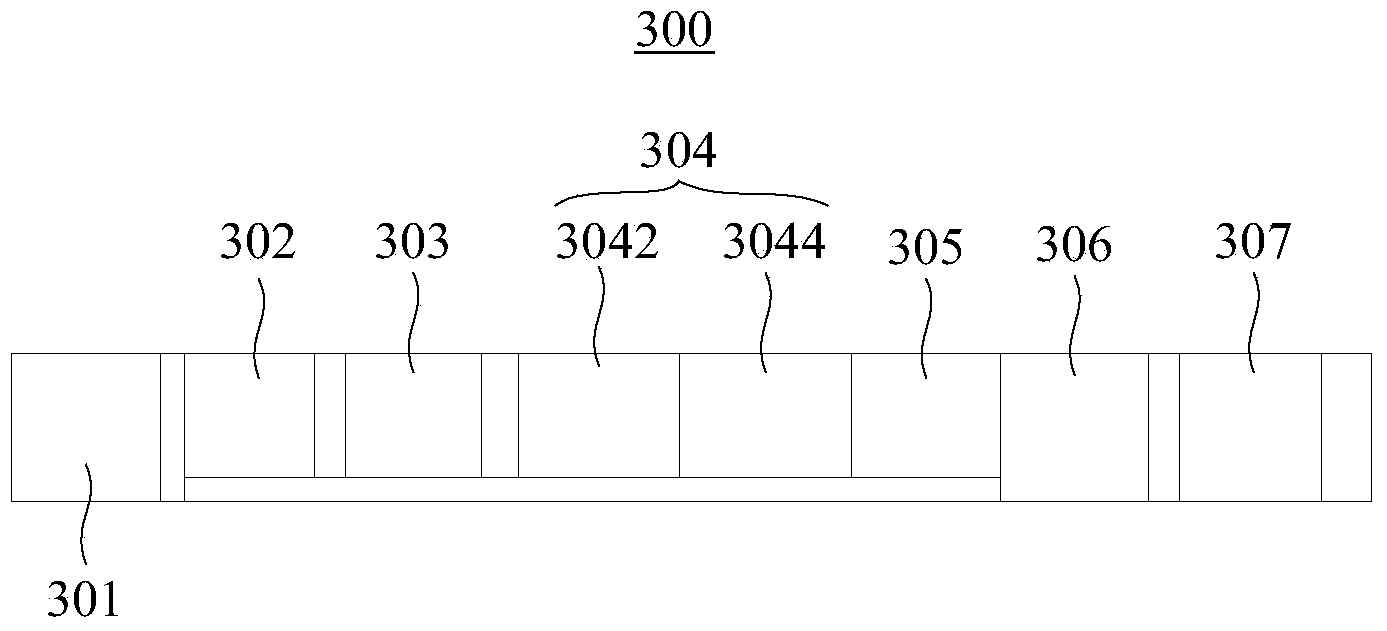

[0062] 2. Use the conveyor belt to level the positioning tray to the film feeding chamber of the horizontal sputtering coating system, place the clean and dry TFT substrate on the positioning tray of the film feeding room with the mechanical arm, and use the photoelectric induction transmission system to place the TFT The positioning tray of the substrate is transferred horizontally into the first transition chamber and the first buffer chamber of the horizontal sputtering coating system in turn; the pressure of the feeding chamber is atmospheric pressure, and the vacuum degree of the first transition chamber is 1*10 -1 Pa the vacuum deg...

Embodiment 2

[0067] 1. Provide TFT substrates, clean the TFT substrates with pure water and lye in turn with a cleaning machine, then perform two-fluid spraying, pure water spraying and high-pressure spraying in sequence, and then dry them with cold air and hot air in sequence, and set them aside; , the pressure of high pressure spraying is 1.3kg / cm 2 ;

[0068] 2. Use the conveyor belt to level the positioning tray to the film feeding chamber of the horizontal sputtering coating system, place the clean and dry TFT substrate on the positioning tray of the film feeding room with the mechanical arm, and use the photoelectric induction transmission system to place the TFT The positioning tray of the substrate is horizontally transported into the first transition chamber and the first buffer chamber of the horizontal sputtering coating system in turn; the pressure of the feeding chamber is atmospheric pressure, and the vacuum degree of the first transition chamber is 3.5*10 -2 Pa, the vacuum ...

Embodiment 3

[0073] 1. Provide TFT substrates, clean the TFT substrates with pure water and lye in turn with a cleaning machine, then perform two-fluid spraying, pure water spraying and high-pressure spraying in sequence, and then dry them with cold air and hot air in sequence, and set them aside; , the pressure of high pressure spraying is 1.7kg / cm2 ;

[0074] 2. Use the conveyor belt to level the positioning tray to the film feeding chamber of the horizontal sputtering coating system, place the clean and dry TFT substrate on the positioning tray of the film feeding room with the mechanical arm, and use the photoelectric induction transmission system to place the TFT The positioning tray of the substrate is horizontally transported into the first transition chamber and the first buffer chamber of the horizontal sputter coating system in turn; the pressure of the feeding chamber is atmospheric pressure, and the vacuum degree of the first transition chamber is 6.8*10 -2 Pa, the vacuum degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com