A silicon micro-gyroscope temperature control and temperature compensation circuit device based on fpga

A silicon micro-gyroscope and circuit device technology, applied in measurement devices, instruments, etc., can solve problems such as unfavorable miniaturization and integration of micro-gyroscopes, incompatibility of MEMS processes, complex structure and process, etc. Eliminate the influence of excess resistance temperature coefficient, and the effect of good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further explained below in conjunction with the accompanying drawings.

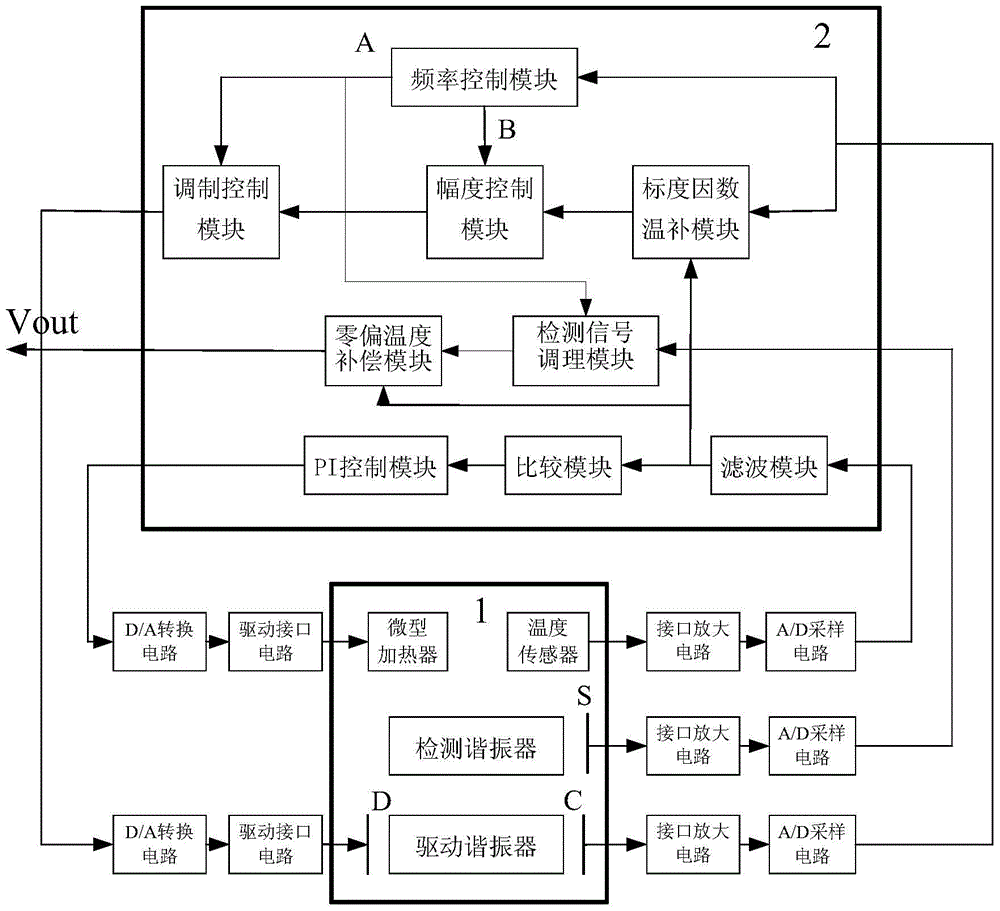

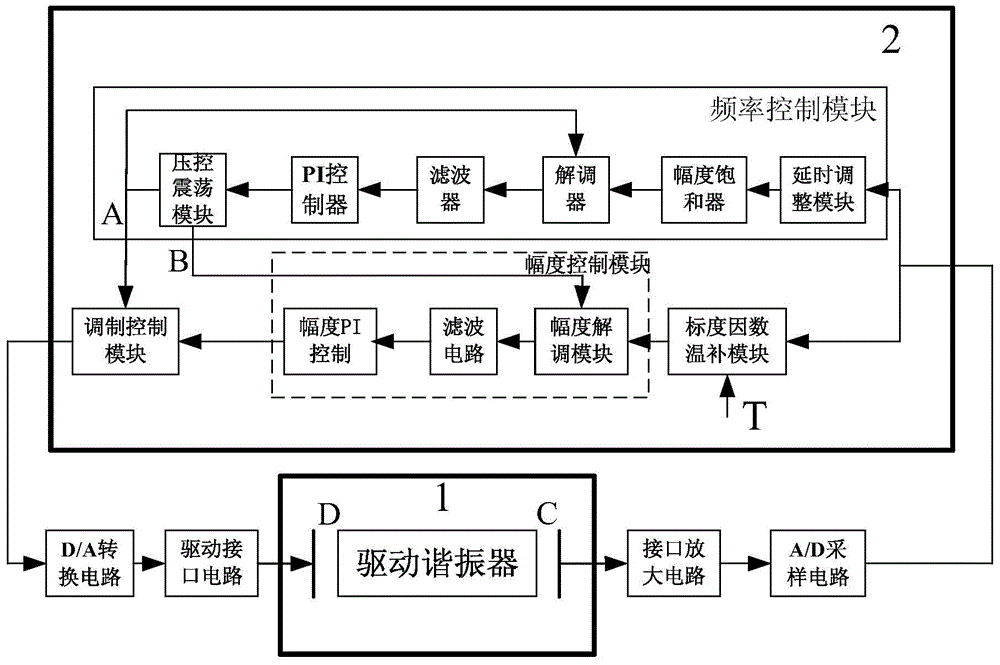

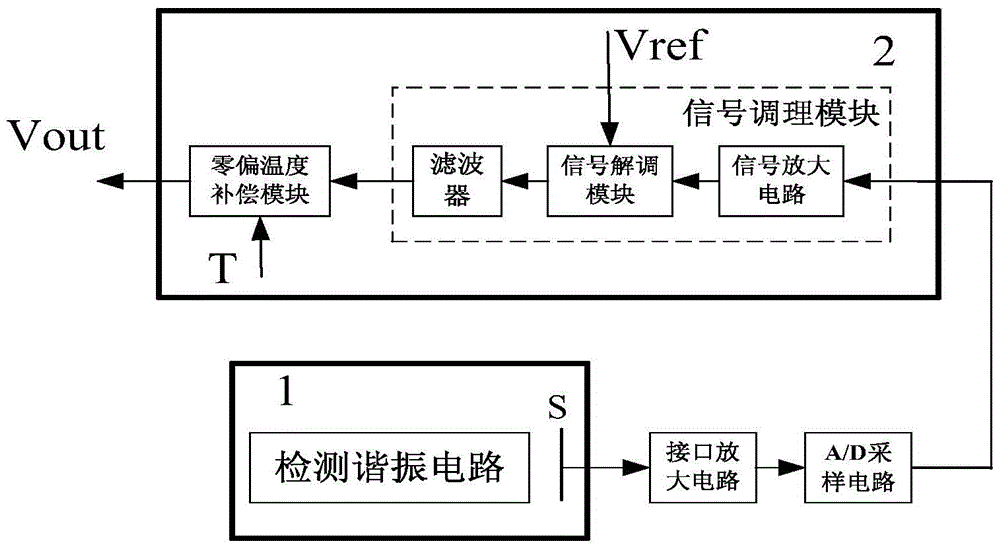

[0031] Such as figure 1 shown, combined with figure 1 , an FPGA-based silicon micro-gyroscope temperature control and temperature compensation circuit device, including a micro-gyroscope integrated with a micro-heater and a temperature sensor, a set of A / D sampling circuits, a set of drive interface circuits, and a set of interface amplifiers circuit and a set of D / A conversion circuits; use the temperature sensor and micro heater integrated in the micro gyroscope to realize the chip-level temperature control and temperature compensation of the silicon micro gyroscope, which has high sensitivity, good repeatability, small inertia, and temperature information reliability High, low power consumption, high control precision and other advantages; at the same time, the FPGA-based digital temperature control and temperature compensation platform reduces the influence of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com