Functional tester with elastic connector

A technology of elastic connectors and testers, which is applied in the direction of electronic circuit testing and measuring device shells, etc., can solve the problems of test connector female PIN wear, affect test results, and affect work efficiency, so as to reduce damage and improve test Efficiency and the effect of increasing the number of times of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

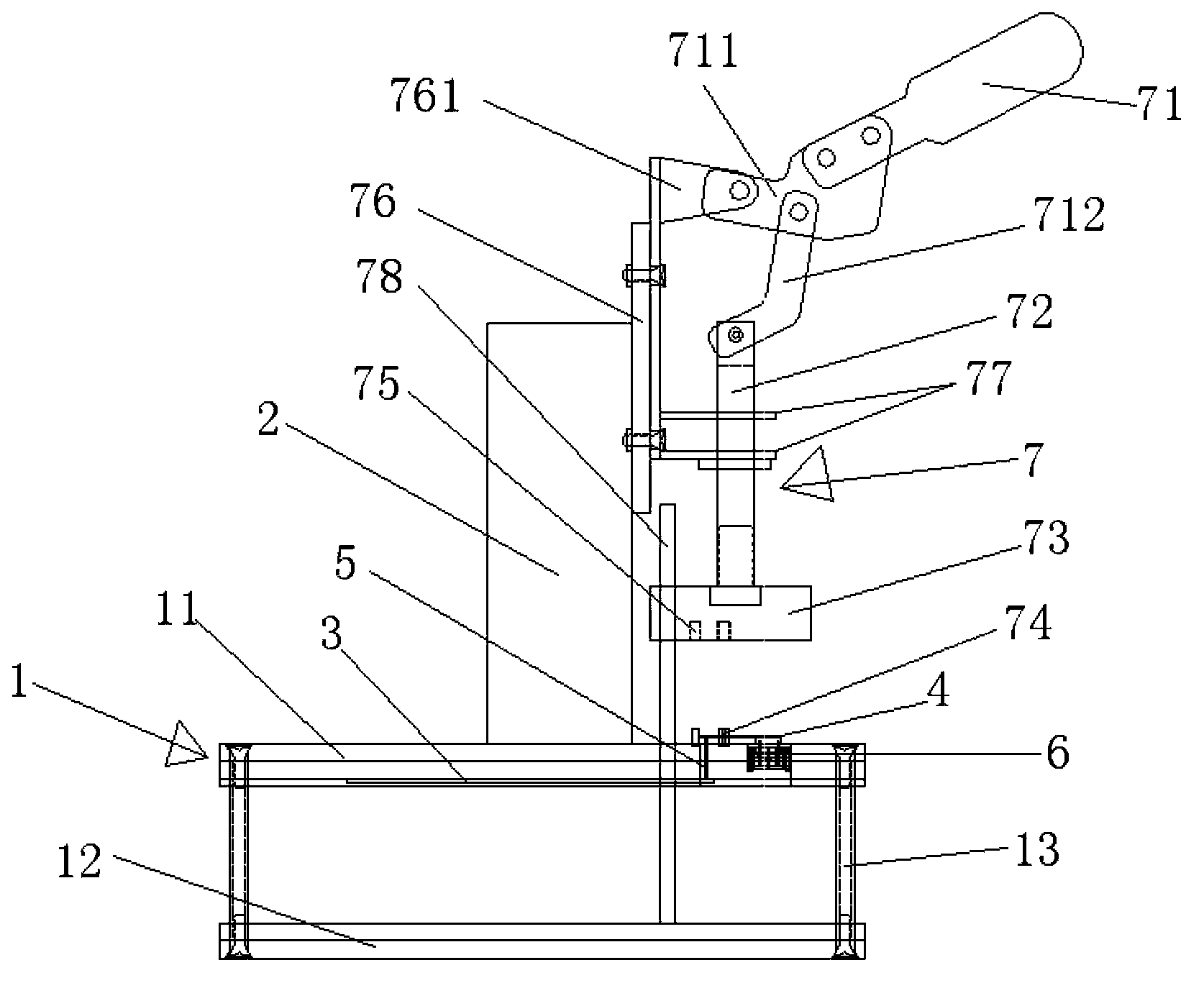

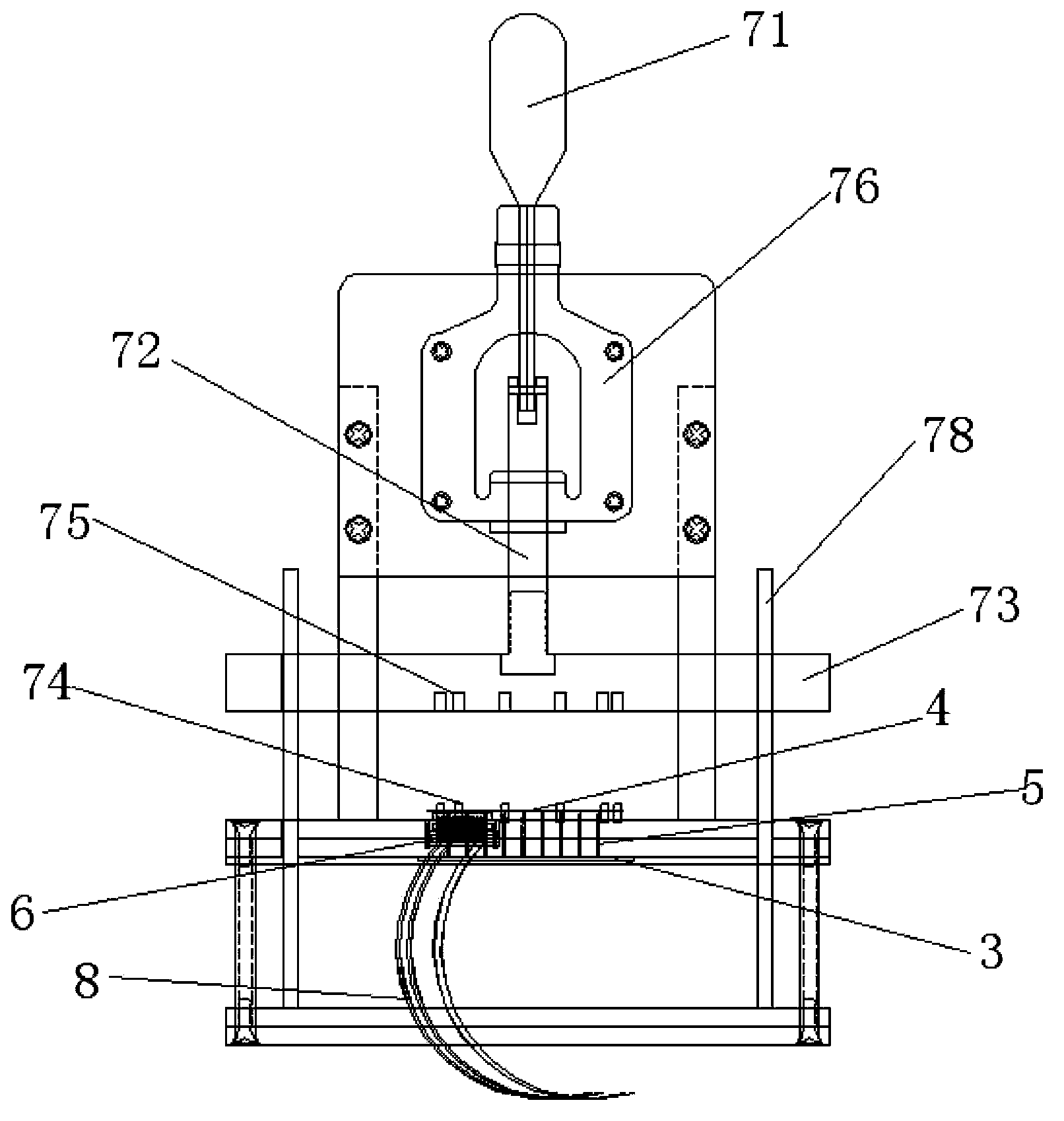

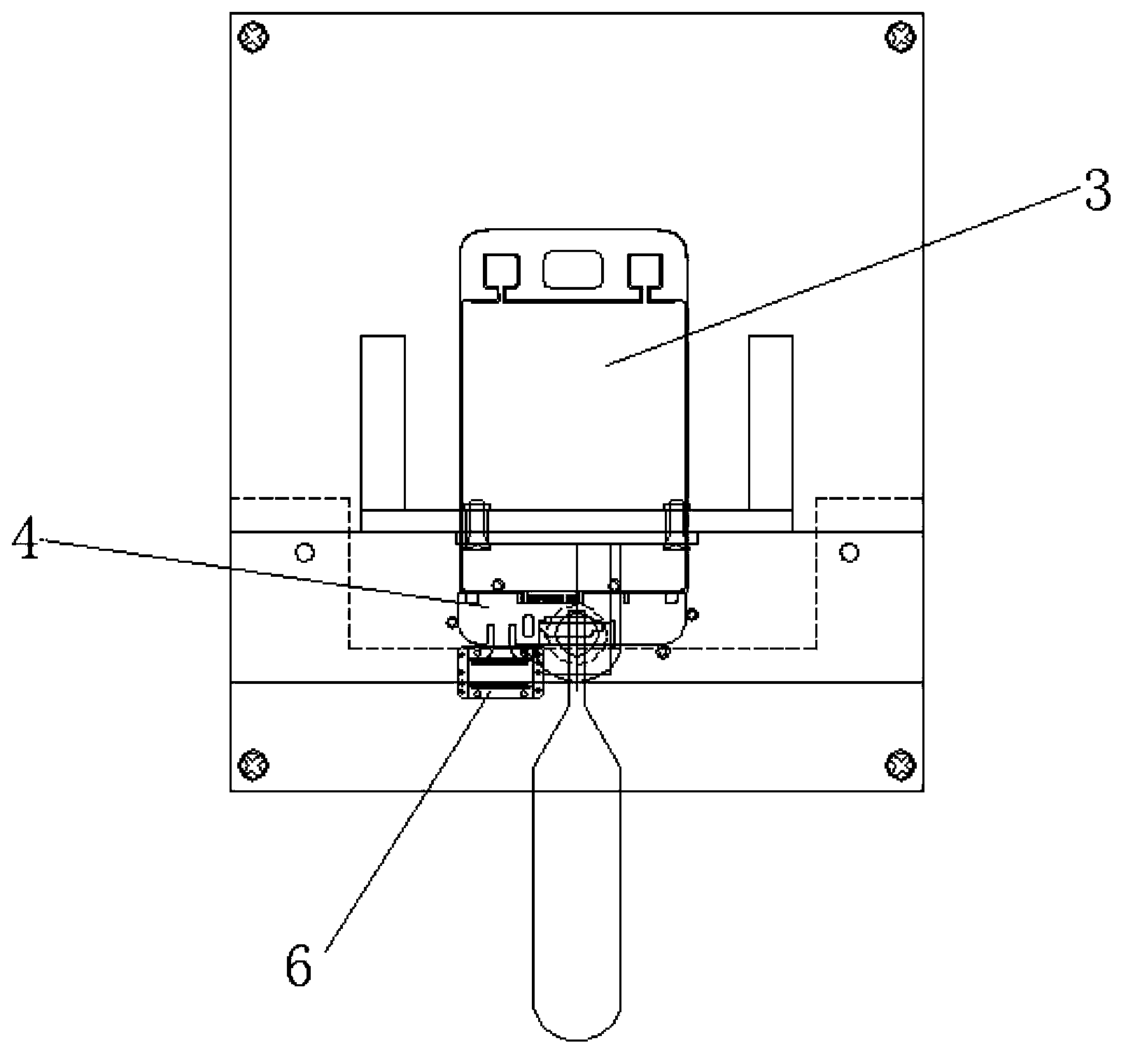

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, an elastic connector function tester includes a base 1, a bracket 2, a TP screen body 3 for testing, a set of double-headed probes 5 matching the electrical connection of the FPC 4 to be tested and an electrical connection with the FPC to be tested. Matching elastic connector 6, the base includes a top plate 11 and a bottom plate 12, the top plate and the bottom plate are positioned and fixed through several pillars 13, and one end of the bracket is fixed on the top plate based on the direction of use On the surface, the other end side is fixedly connected with a first positioning mechanism 7, and the first positioning mechanism can be positioned on the top surface of the top plate and separated from the FPC to be tested, and the top plate is additionally provided with a second positioning mechanism, and the first positioning mechanism The second positioning mechanism can locate and break aw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com