Coaxial three-mirror zooming optical system based on photoisomerization materials

A photoisomerization and optical system technology, applied in the field of aerospace optical remote sensors, can solve the problems that the structural design is difficult to ensure high stability, the mechanical zoom solution is not very suitable, and the engineering feasibility is reduced, so as to achieve high precision Temperature and pointing control, easy to control high-precision temperature and pointing, with the effect of engineering feasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

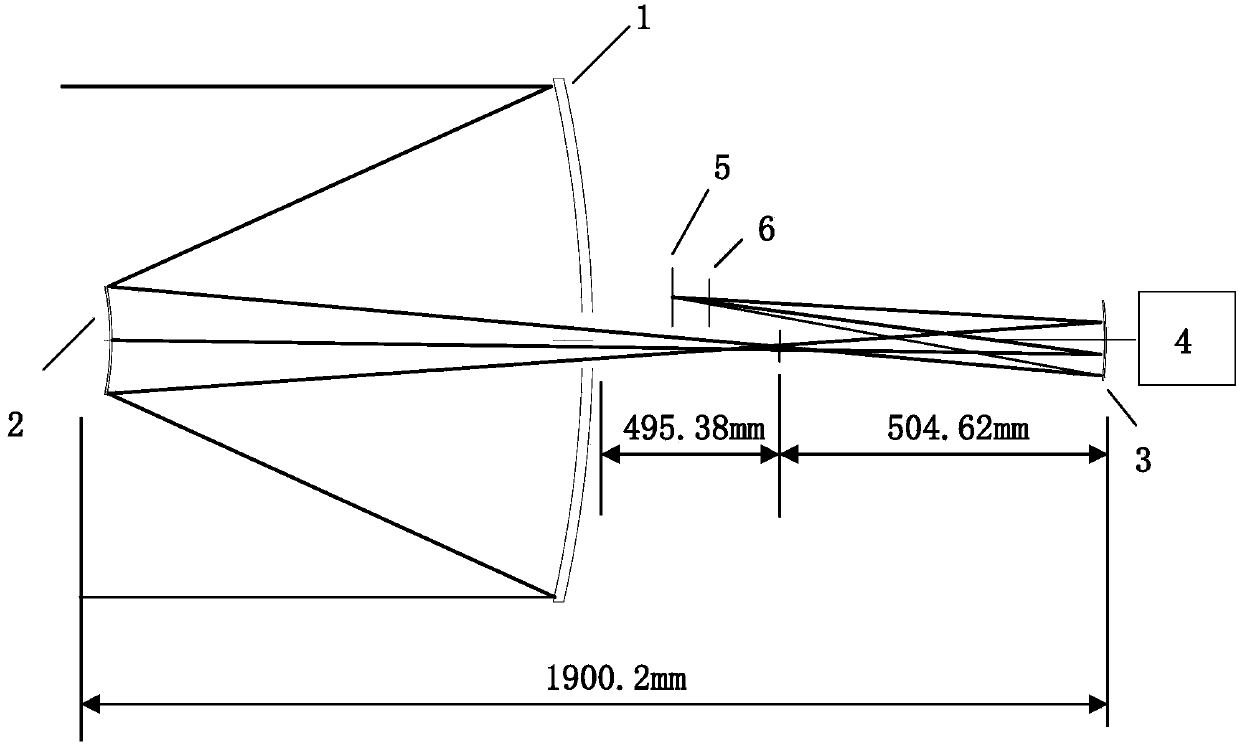

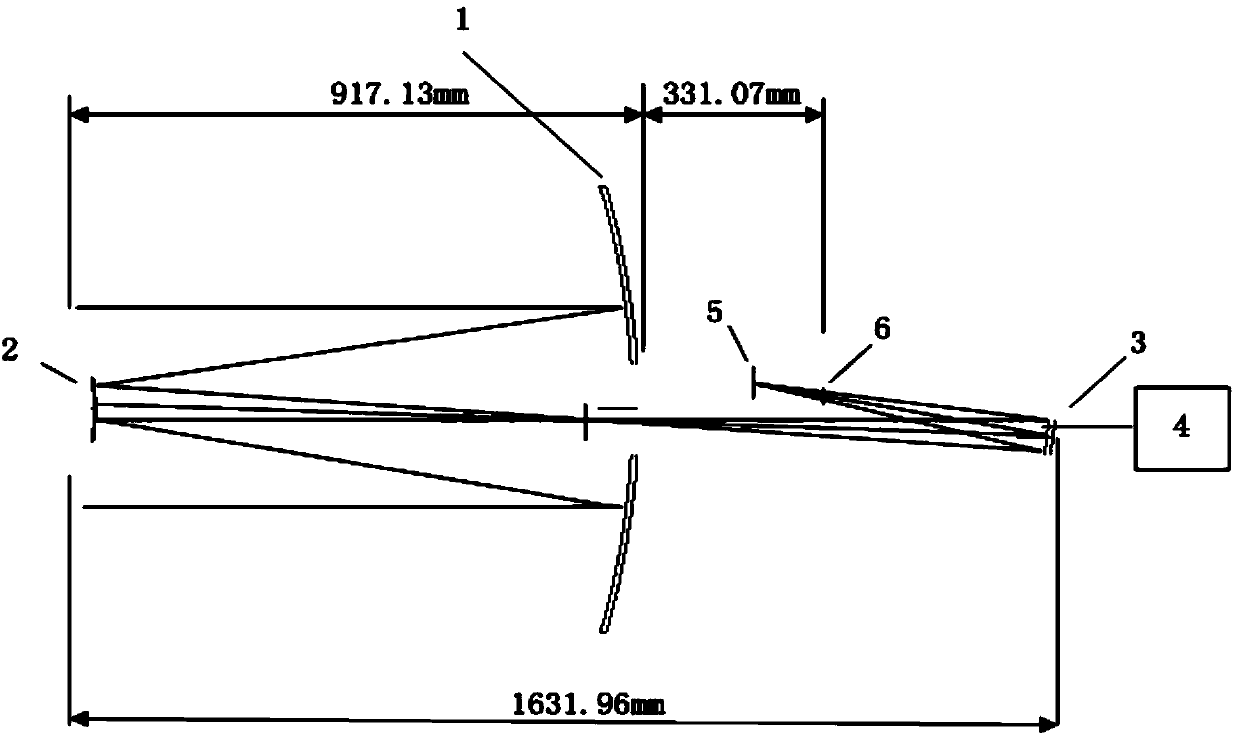

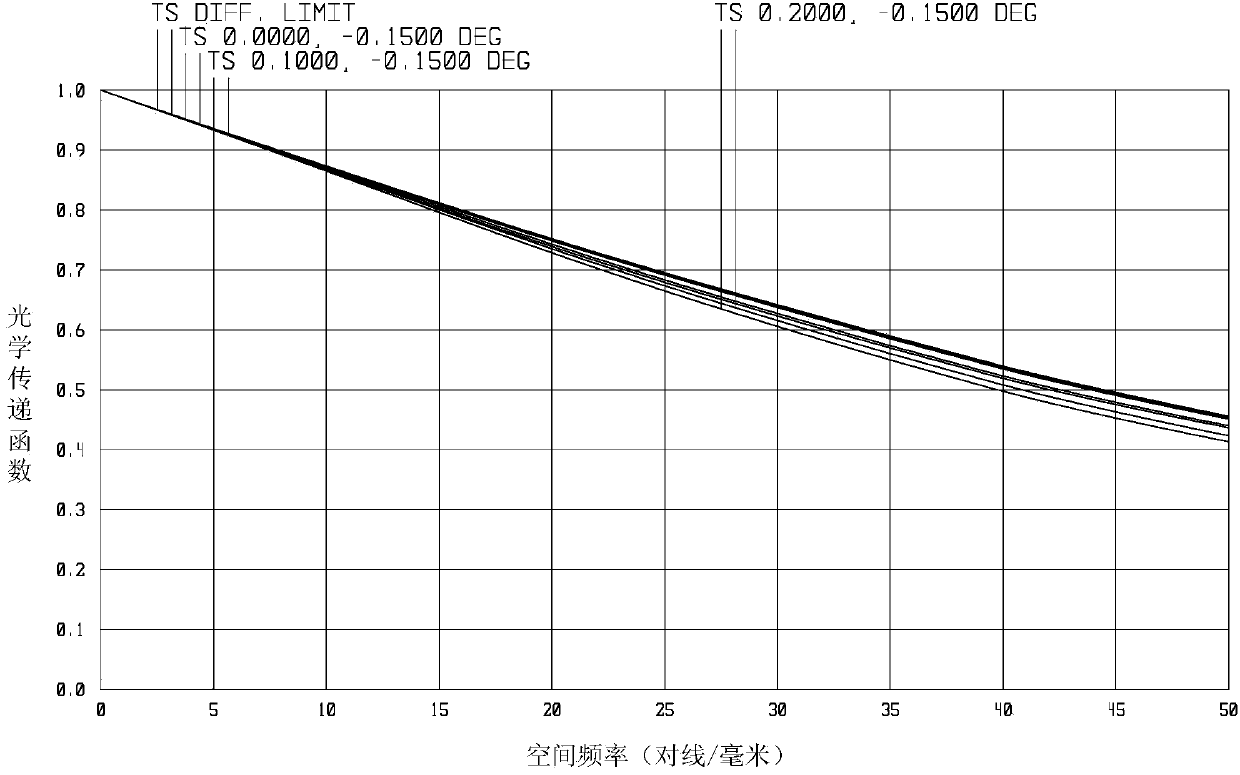

[0018] The working spectrum of the embodiment of the present invention is 0.45-0.8 μm, the entrance pupil diameter is 1000mm in the long focal length mode, the focal length of the optical system is 12m, the full field of view is 0.4°, and the total system length is 1900.02mm. In the short focal length mode, the entrance pupil diameter is 500mm, the focal length of the optical system is 4m, the full field of view is 3°, and the total length of the system is 1631.96mm. In the telephoto mode, the implementation scheme is as follows figure 1 As shown, the optical system of the present invention includes: a primary mirror 1 , a secondary mirror 2 , a third mirror 3 , a drive motor 4 , a focal plane detector 5 and a variable aperture diaphragm 6 . The primary mirror 1, the secondary mirror 2, the third mirror 3 and the variable aperture diaphragm 6 are coaxial, the primary mirror 1 and the secondary mirror 2 form a classic R-C system, and form a real image, which passes through the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com