Motor vehicle drive axle design method

A technology for drive axles and motor vehicles, applied in computing, instruments, electrical digital data processing, etc., can solve the problems of wasting man-machine resources, long design cycle, and low design automation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

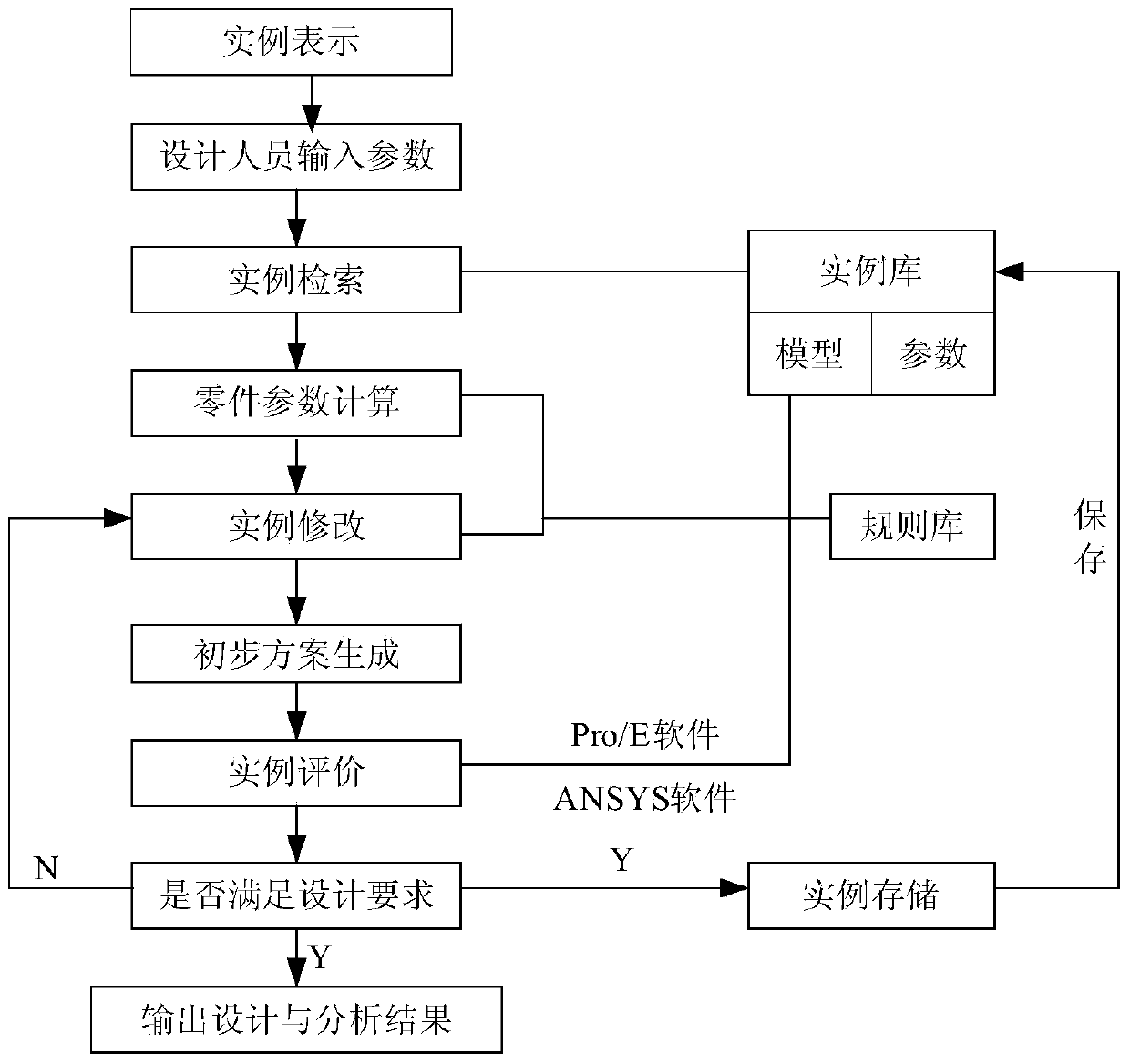

Method used

Image

Examples

Embodiment

[0030] This embodiment designs a heavy-duty drive axle. For the attribute of its rated load, according to experience, the value range of this attribute is 10000-16000, C 1 The attribute value in the instance is 13000, C 2 The attribute value in the instance is 11500, so C 1 with C 2 The similarity of instances on the rated load property is:

[0031] sim ( c 1 k , c 2 k ) = 1 - | 13000 - 11500 | 16000 - 10000 = 0.75

[0032]Taking two examples as examples, the similarity calculation process is described in detail, as shown in Table 1.

[0033] Table 1: Ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com