plasma source

A plasma source, plasma technology, applied in the direction of plasma, ion beam tube, cathode ray tube/electron beam tube, etc., can solve the problems of need to replace immediately, the thickness of the prevention plate is thin, avoid collision, improve operation rate, the effect of prolonging the exchange period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

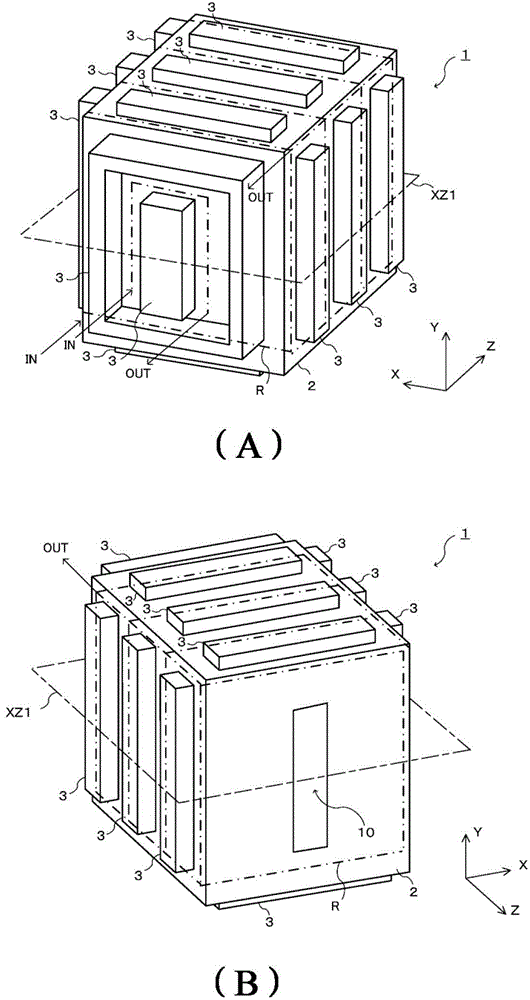

[0055] in figure 1 Of (A), figure 1 In (B), a perspective view showing the appearance of the plasma source 1 is drawn. in figure 1 (A) and figure 1 In (B), it means that the same plasma source 1 is viewed from different directions. The X-axis, Y-axis, and Z-axis shown in the figure are perpendicular to each other.

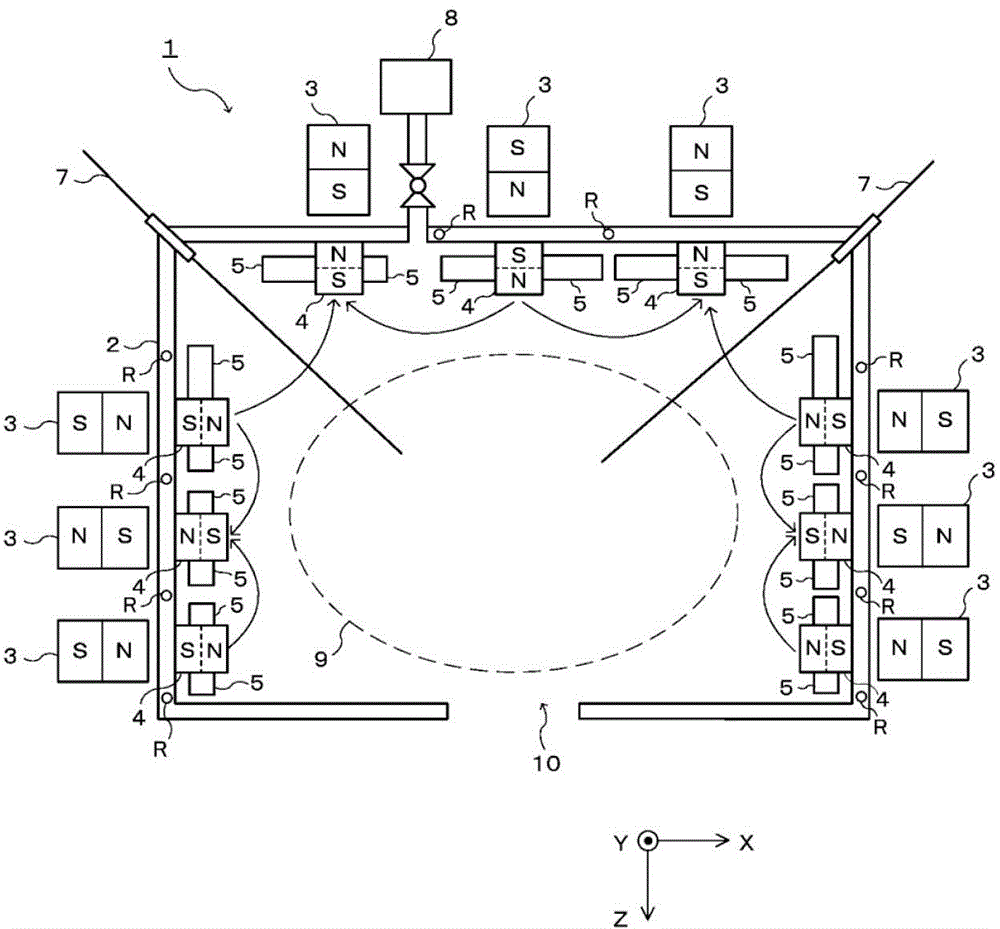

[0056] figure 1 Of (A), figure 1 The plasma generation vessel 2 constituting the plasma source 1 described in (B) has a rectangular parallelepiped shape, and a discharge port 10 is formed on the surface of the plasma generation vessel 2 on the Z direction side. When the ion beam, electron beam, and plasma are drawn from the inside of the plasma source 1 to the outside of the plasma source 1, a plurality of permanent magnets 3 are arranged opposite to each other on the other surface. These permanent magnets 3 generate a cutting magnetic field inside the plasma generation container 2.

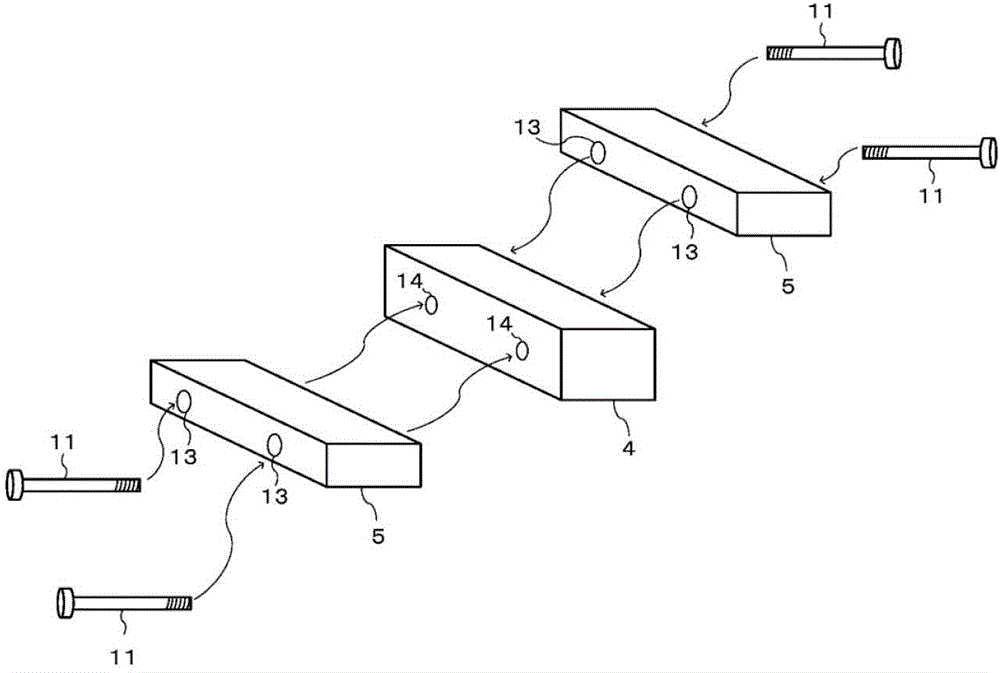

[0057] The plurality of permanent magnets 3 that generate a slicing magnetic field a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com