Manufacturing method of X-ray flat panel detector

A technology of flat panel detection and manufacturing method, which is applied to radiation control devices and other directions, can solve the problems of breakdown of amorphous silicon thin film transistors, large charge changes, and lower production yields of X-ray flat panel detection devices, so as to improve production yields. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

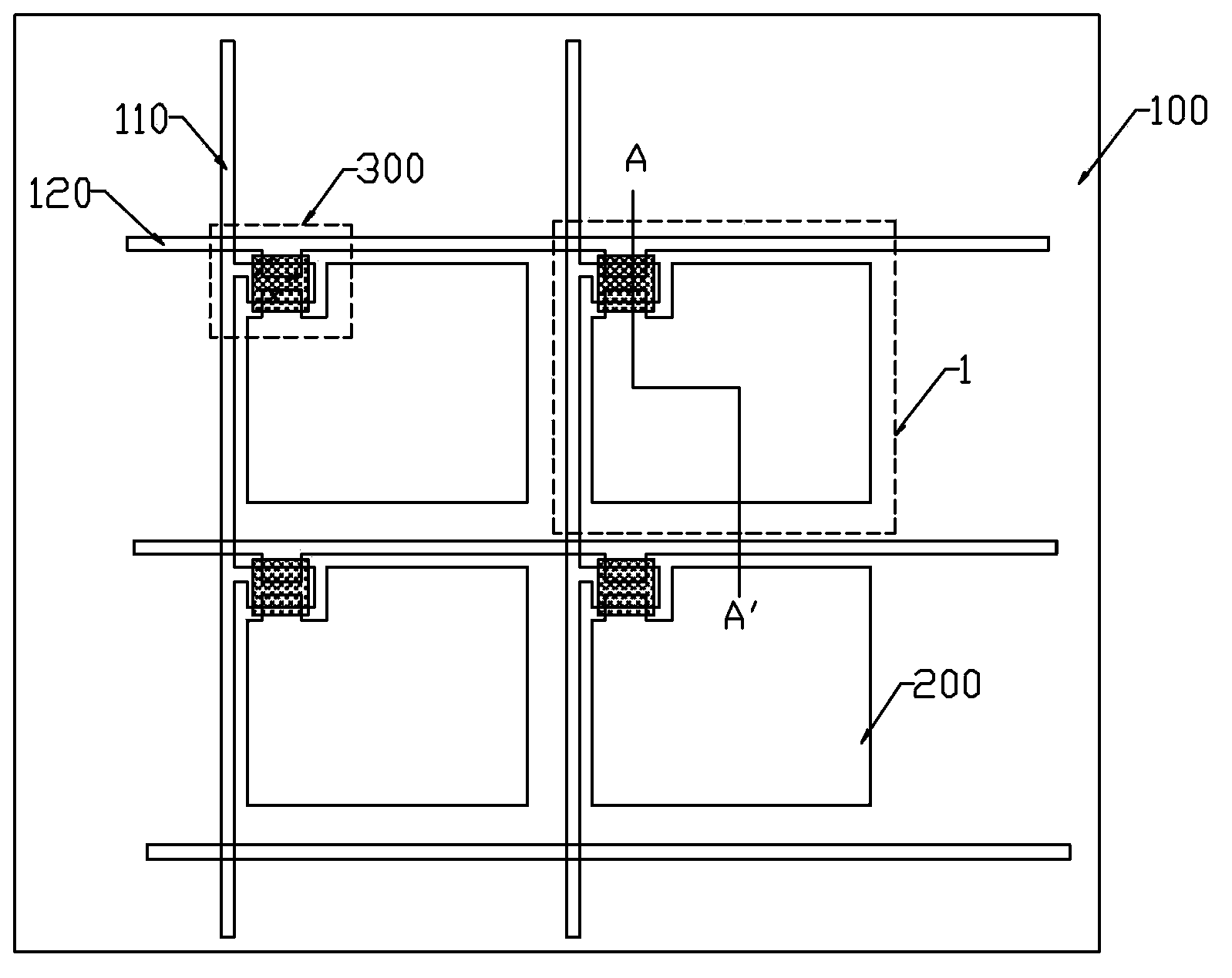

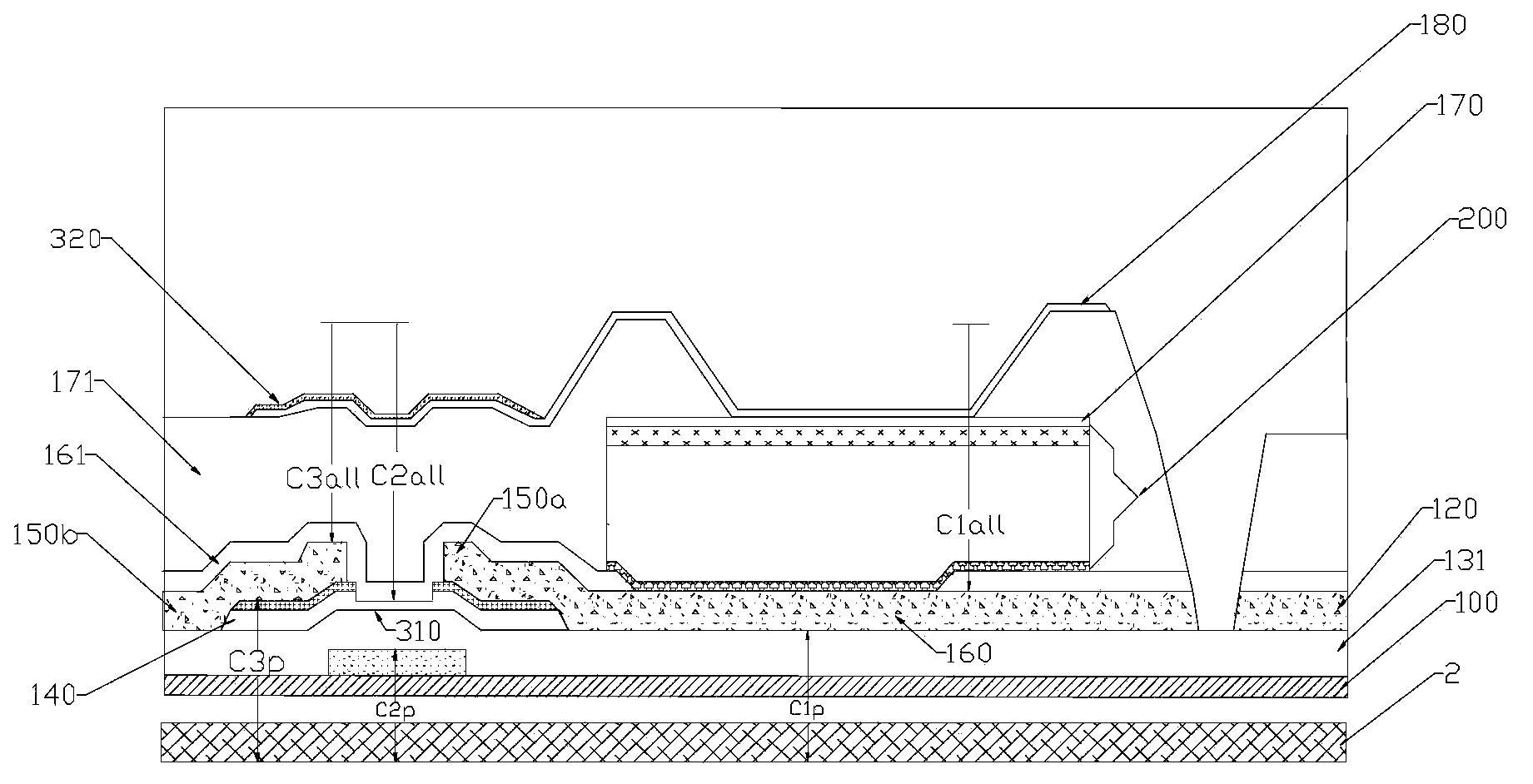

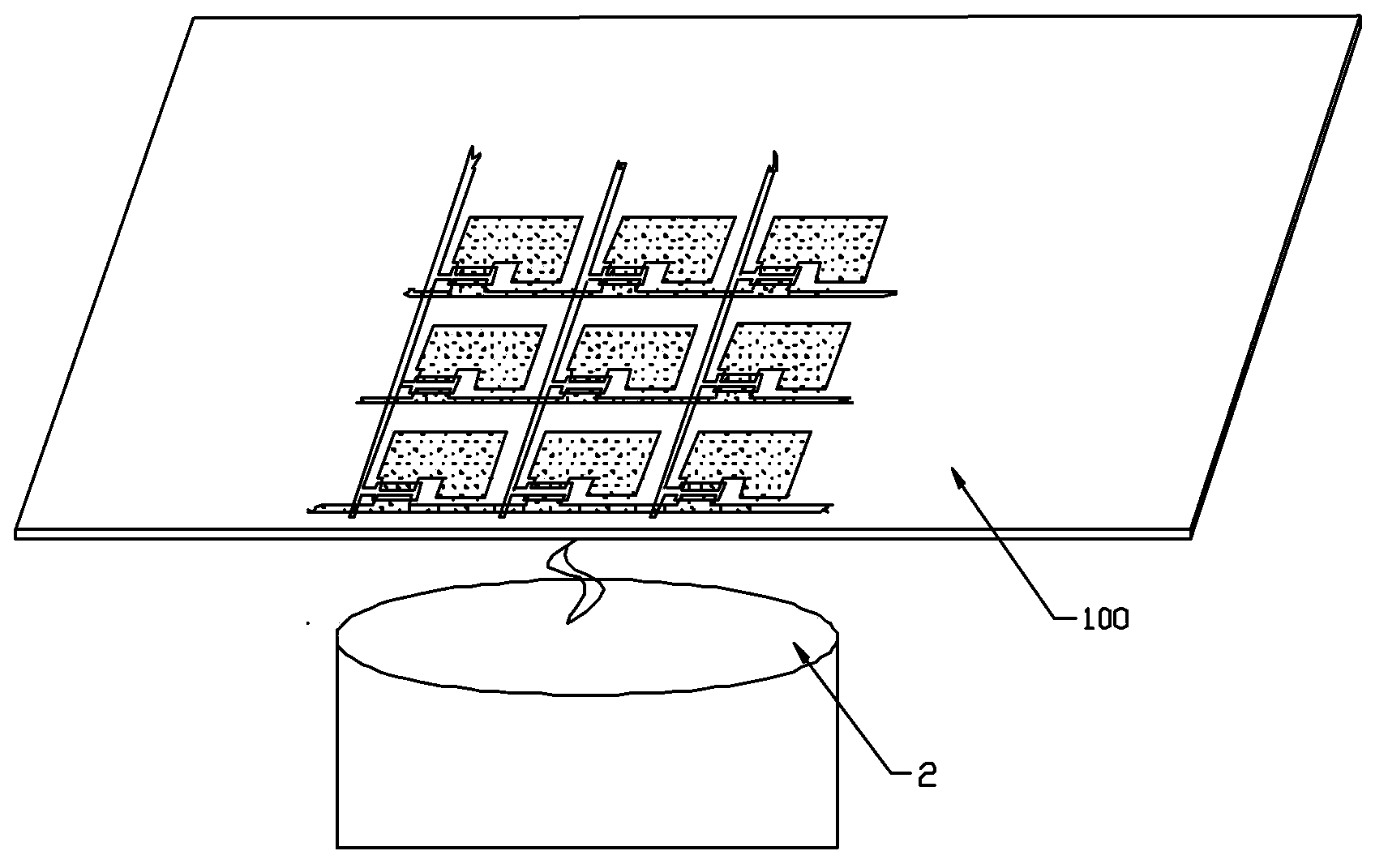

[0081] First, if Figure 4 As shown, a substrate 100 is provided, and the substrate 100 is a glass substrate 100. The material of the substrate 100 of the present invention is not limited to glass, but can also be high temperature resistant organic matter, metal, quartz or diamond, or other materials that can withstand the TFT process To implement temperature, the surface of the panel is flat. The first conductive layer is sputtered on the substrate 100, and then a photoresist is coated on the first conductive layer, and the photoresist is exposed using a mask plate with a specific pattern, and the patterned the first conductive layer; then wet etching the first conductive layer to form the gate 130 and the scanning lines; finally, stripping the photoresist and cleaning it. Wherein, the first conductive layer may be made of metal materials such as aluminum, neodymium, molybdenum, chromium and alloys thereof.

[0082] Next, if Figure 5 As shown, the gate insulating layer 13...

Embodiment 2

[0094] Compared with Embodiment 1, in this embodiment, the bottom electrode 160 (source electrode 150 a ) of the photoelectric conversion element 200 is electrically connected to the scanning line through the connection part 190 as a whole. At the moment when the support pillar 2 contacts or separates from the bottom surface of the substrate 100 , a large amount of electrostatic charge generated by the bottom electrode 160 (source electrode 150 a ) is discharged through the scanning line. The manufacturing steps before the deposition of the gate insulating layer 131 and after the formation of the first passivation layer 161 are the same or similar to those of the first embodiment, and will not be repeated here. The differences of this embodiment will be described in detail below with reference to the drawings.

[0095] After forming the silicon islands of the active layer 140, as Figure 14 As shown, the gate insulating layer is patterned, and a part of the scan line 110 is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com