Full-positive-dispersion er-doped optical-fiber laser device based on optical-grating filtering and adjustment method thereof

An erbium-doped fiber, total positive dispersion technology, which is applied in the control field of a total positive dispersion erbium-doped fiber laser, and can solve problems such as difficult total positive dispersion fiber lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

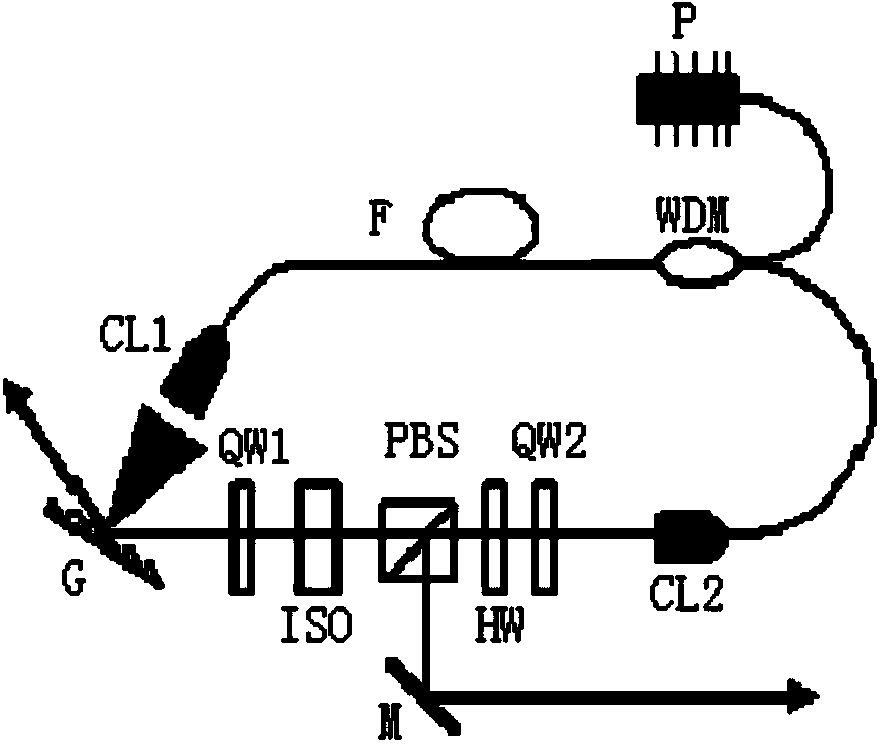

[0025] Such as figure 1 As shown, the total positive dispersion erbium-doped fiber laser of the present embodiment includes: polarization beam splitter prism PBS, isolator ISO, first 1 / 4 slide QW1, grating G, first collimator CL1, gain fiber F, wavelength division The multiplexer WDM, the second collimator CL2, the second 1 / 4 slide QW2 and the 1 / 2 slide HW form a ring resonant cavity; the pump source P is coupled to the gain fiber through the wavelength division multiplexer WDM. The P polarization component of the pulse oscillates in the ring resonant cavity through the polarization beam splitter PBS, and the S polarization component of the pulse is reflected by the polarization beam splitter PBS, and then reflected by the plane mirror M, as a stable output.

[0026] The pumping source P is pumped reversely by a 974nm single-mode diode with an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com