On-line plasma cleaning method

A technology of plasma cleaning and cleaning area, which is applied in the field of ion cleaning, can solve the problems of high cost of material box, insufficient cleaning, and inability to clean the surface of the frame, and achieve the effect of eliminating pollution and oxides and improving bonding adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

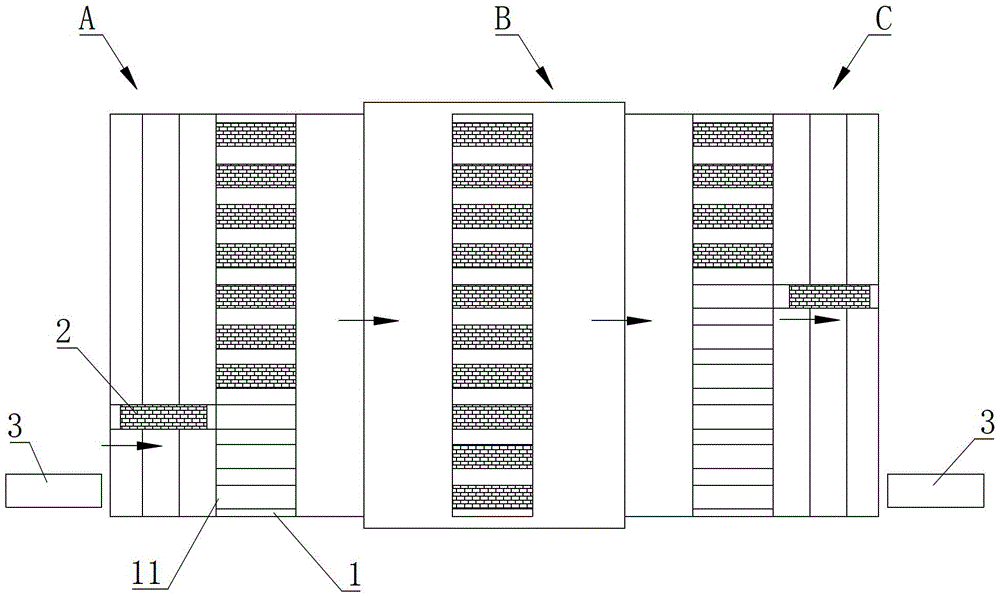

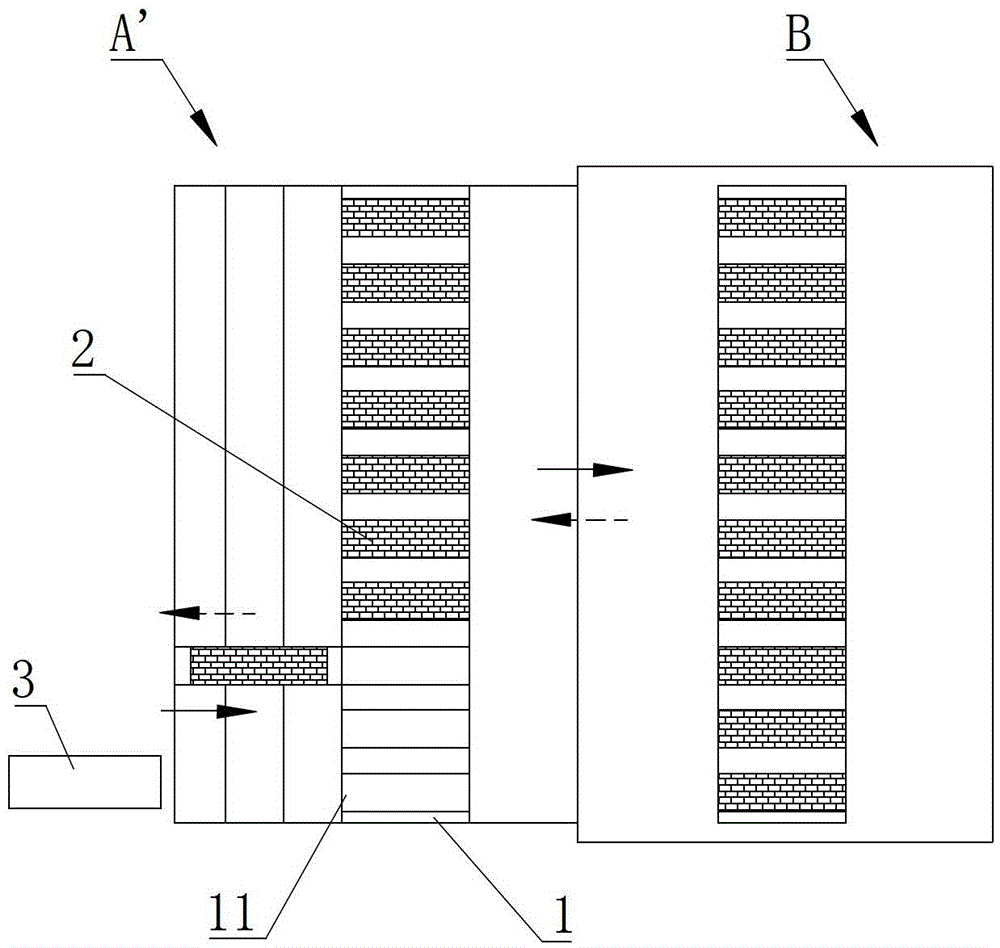

[0026] As the chip carrier of the integrated circuit, the lead frame is a kind of electrical connection between the lead-out end of the internal circuit of the chip and the external lead by means of a bonding gold wire. Most of the semiconductor integrated blocks need to use lead frames, which are important basic materials in the electronic information industry. In the following description, the method of the present invention is further described by taking the cleaning of the lead frame as an example. Such as figure 1 As shown, the plasma cleaning method of the present invention adopts an automatic online plasma cleaning system for cleaning. The system includes sequentially arranged loading area A, cleaning area B, unloading area C, and loading platform 1. Under the control of the mechanism, it can reciprocate between the loading area A, the cleaning area B, and the unloading area C. The loading platform 1 is provided with frame placement grooves 11 at intervals along the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com