Molecular sieve forming product and preparation method thereof

A technology of molecular sieves and moldings, which is applied in the field of molecular sieves to achieve the effect of improving utilization and reducing water consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

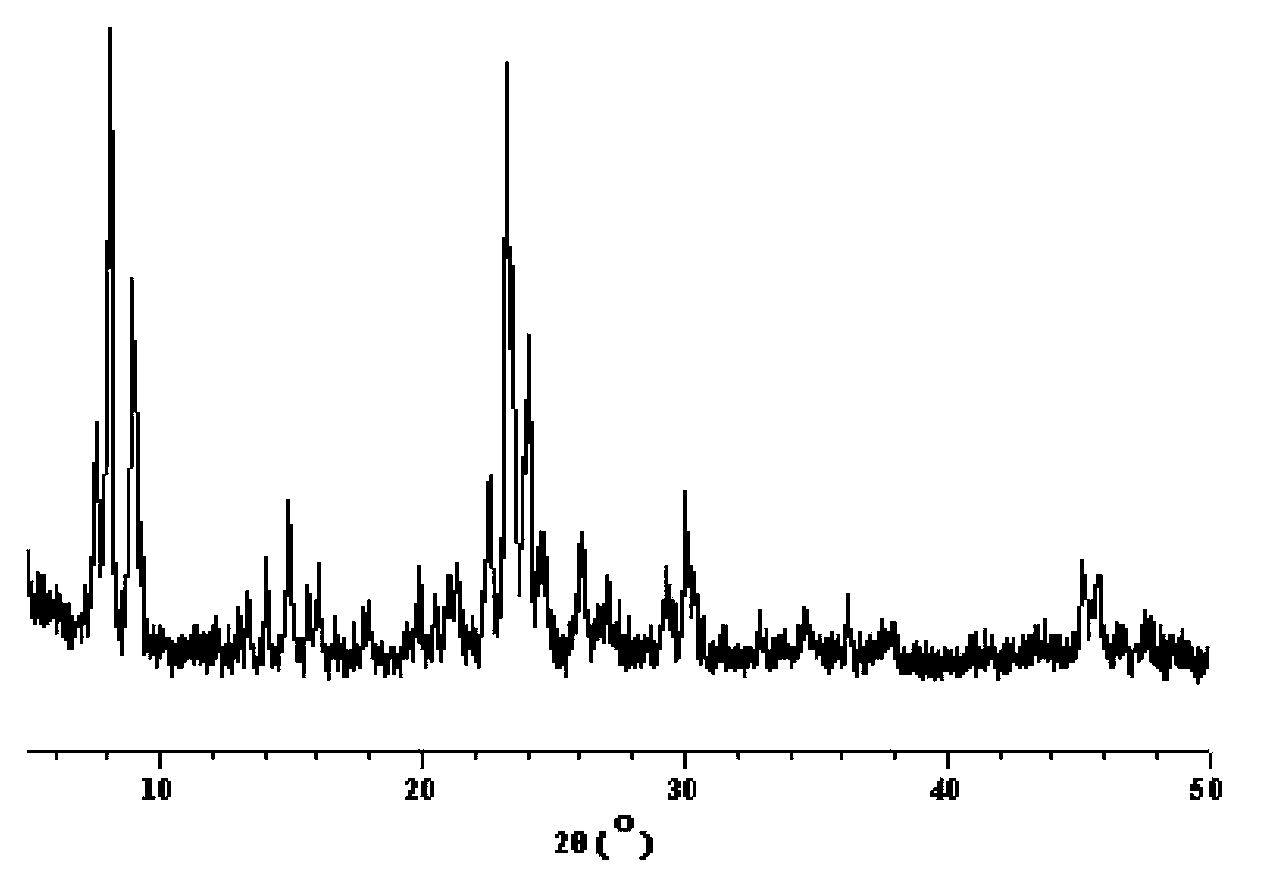

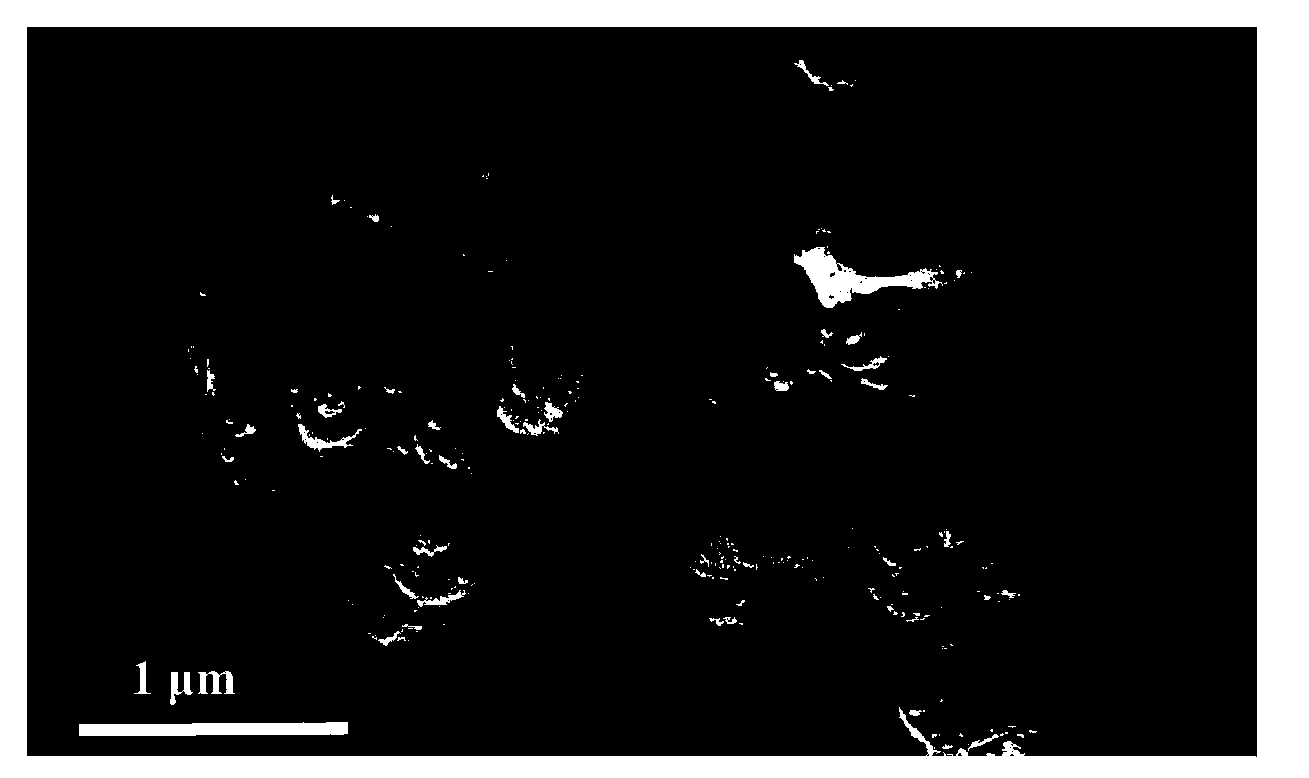

[0028] Mix ZSM-5 molecular sieve with a molar ratio of silicon to aluminum of 50 and pseudoboehmite at a weight ratio of 3:1, add 19.2 grams of 85% orthophosphoric acid and 30 mL of distilled water, and stir well; add 6.4 grams of triethylamine, stir uniform. Kneading, extrusion molding. Put into the crystallization kettle. Hydrothermal crystallization at 125°C for 6 hours. Next, hydrothermal crystallization was carried out at 160° C. for 24 hours. Take it out and bake it at 580°C. Sampling, pulverization and characterization. XRD characterization results show that (see figure 1 ), in addition to the ZSM-5 crystal form, there are AlPO 4 -5 crystal form appears; SEM characterization results show that there are small particles attached to the surface of block ZSM-5 (see figure 2 ).

Embodiment 2

[0030] Mix ZSM-5 molecular sieve with a molar ratio of silicon to aluminum of 50 and pseudoboehmite at a weight ratio of 4:1; add 3.6 grams of triethylamine and 30 mL of distilled water, and stir well; add 9.65 grams of 85% orthophosphoric acid, and stir uniform. Kneading, extrusion molding. Put into the crystallization kettle. Hydrothermal crystallization at 150°C for 4 hours. Next, hydrothermal crystallization was carried out at 200° C. for 10 hours. Take it out and bake it at 580°C to obtain a bar-shaped molecular sieve.

Embodiment 3

[0032] Mix ZSM-5 molecular sieve with a silicon-aluminum molar ratio of 50 and pseudoboehmite at a weight ratio of 5:1, add 19.6 grams of 85% orthophosphoric acid, and stir evenly; add 8.1 grams of triethylamine and 10 mL of distilled water, and stir uniform. Kneading, extrusion molding. Put into the crystallization kettle. Hydrothermal crystallization at 100°C for 24 hours. Then, hydrothermal crystallization was carried out at 150° C. for 48 hours. Take it out and bake it at 580°C to obtain a bar-shaped molecular sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com