High-salinity agricultural irrigation back water and soil improvement constructed wetland substrate structure and constructing method

A soil improvement and artificial wetland technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve problems such as inability to increase soil organic matter content, and little improvement in soil fertility , to achieve the effect of preventing water leakage, strong application value and low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

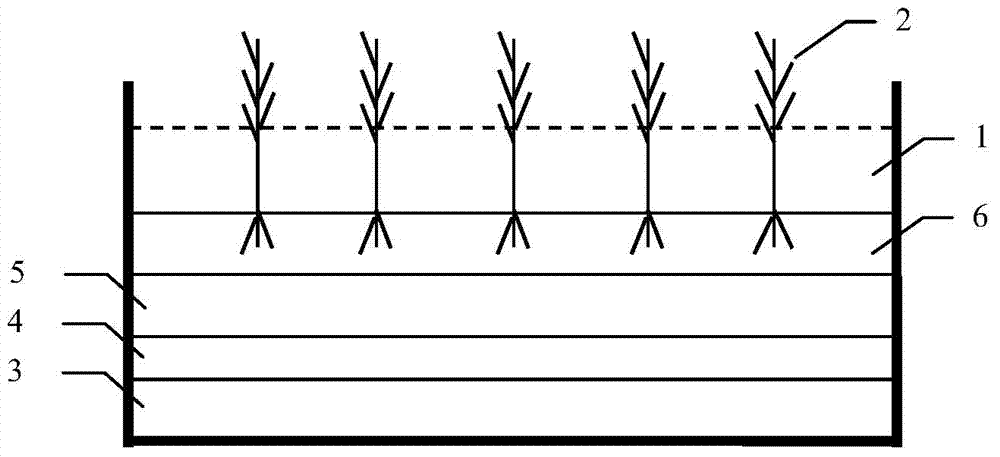

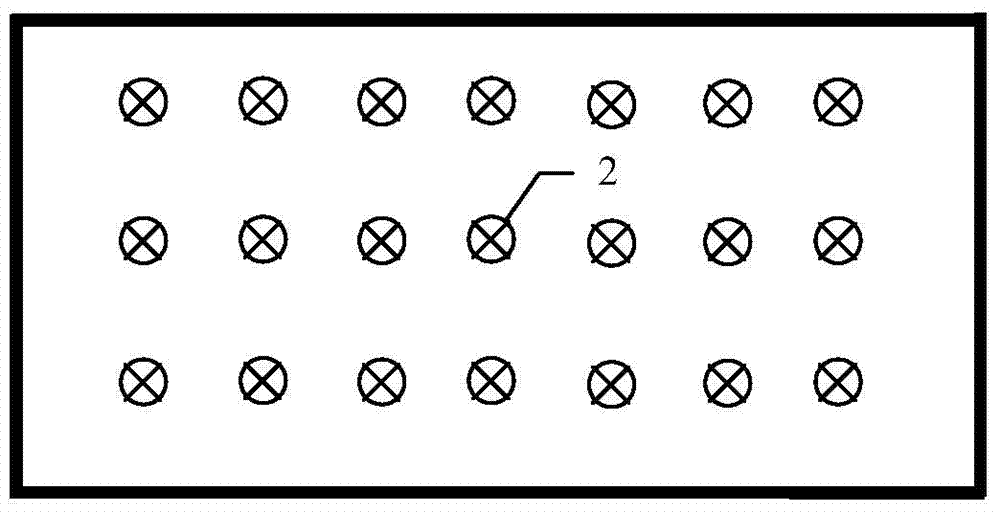

[0018] The size of the area of the present invention can be determined according to the actual situation. The substrate uses non-polluting soil, desulfurized gypsum, fly ash, coal gangue and gravel, which are respectively from bottom to top: 30cm gravel layer, 20cm coal gangue layer, 30cm fly ash and desulfurization Gypsum mixed layer, 20cm non-polluted soil layer, a total of 100cm. The quality of the soil matrix has reached the second level of the soil environmental quality standard (GB15618-1995). The ratio of fly ash and desulfurized gypsum is 1:1, so that the pH of the mixture is 7, and the top is covered with uncontaminated soil, which is conducive to the growth of wetland plants. The fly ash of the present invention can intercept the salt ions in the water body through adsorption, the desulfurization gypsum can intercept the salt ions in the water body through the displacement reaction, and the coal gangue has a pH of about 5, which can neutralize the alkalinity in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com