Preparation method of continuous long glass fiber reinforced thermoplastic nylon and equipment for preparing thermoplastic nylon

A technology of reinforced thermoplastic and long glass fiber, which is applied in the field of preparation of continuous long glass fiber reinforced thermoplastic nylon to achieve the effects of fast line speed, low processing cost and high material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment relates to a method for preparing continuous long glass fiber reinforced thermoplastic nylon, the method comprising the following steps:

[0032] Step 1, adding glass fibers and a compatibilizer to a reaction tank for grafting reaction to obtain product A;

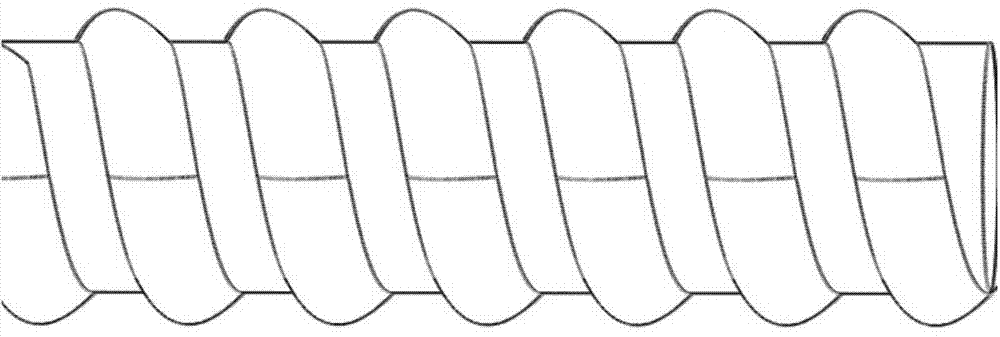

[0033] Step 2, the product A enters the infiltration unit for treatment, is pulled out, cooled and dried.

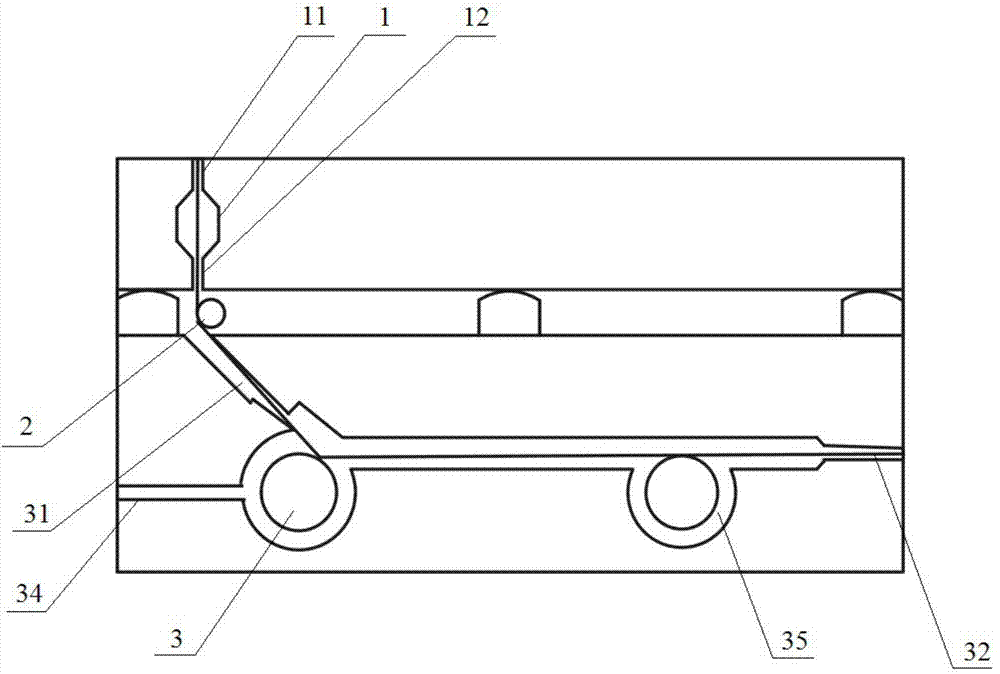

[0034] This embodiment also relates to the aforementioned equipment for the preparation method of continuous long glass fiber reinforced thermoplastic nylon. The equipment includes: a housing, a reaction tank, and an infiltration unit. Carbon and nitriding treated wear-resistant steels, such as figure 2 shown.

[0035] The reaction tank is provided with a reaction tank glass fiber inlet and a reaction tank glass fiber outlet.

[0036] The infiltration unit includes: nylon import channel inlet, glass fiber inlet, glass fiber outlet, glass fiber dispersing roller, nylon channel, the glass fib...

Embodiment 2

[0044] This embodiment relates to a method for preparing continuous long glass fiber reinforced thermoplastic nylon, the method comprising the following steps:

[0045] Step 1, adding glass fibers and a compatibilizer to a reaction tank for grafting reaction to obtain product A;

[0046]Step 2, the product A enters the infiltration unit for treatment, is pulled out, cooled and dried.

[0047] This embodiment also relates to the aforementioned equipment for the preparation method of continuous long glass fiber reinforced thermoplastic nylon. The equipment includes: a housing, a reaction tank, and an infiltration unit. Carbon and nitriding treated wear-resistant steels, such as figure 2 shown.

[0048] The reaction tank is provided with a reaction tank glass fiber inlet and a reaction tank glass fiber outlet.

[0049] The infiltration unit includes: nylon inlet channel inlet, glass fiber inlet, glass fiber outlet, glass fiber dispersing roller, nylon channel, the glass fiber...

Embodiment 3

[0057] This embodiment relates to a method for preparing continuous long glass fiber reinforced thermoplastic nylon, the method comprising the following steps:

[0058] Step 1, adding glass fibers and a compatibilizer to a reaction tank for grafting reaction to obtain product A;

[0059] Step 2, the product A enters the infiltration unit for treatment, is pulled out, cooled and dried.

[0060] This embodiment also relates to the aforementioned equipment for the preparation method of continuous long glass fiber reinforced thermoplastic nylon. The equipment includes: a housing, a reaction tank, and an infiltration unit. Carbon and nitriding treated wear-resistant steels, such as figure 2 shown.

[0061] The reaction tank is provided with a reaction tank glass fiber inlet and a reaction tank glass fiber outlet.

[0062] The infiltration unit includes: nylon inlet channel inlet, glass fiber inlet, glass fiber outlet, glass fiber dispersing roller, nylon channel, the glass fibe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com