Cable threading device and cable threading method for steel strand stay cables

A technology of steel strand and stay cable, which is applied to the cable threading device of steel strand stay cable and the field of cable threading, and achieves the effects of cost saving, convenient selection and adjustable power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

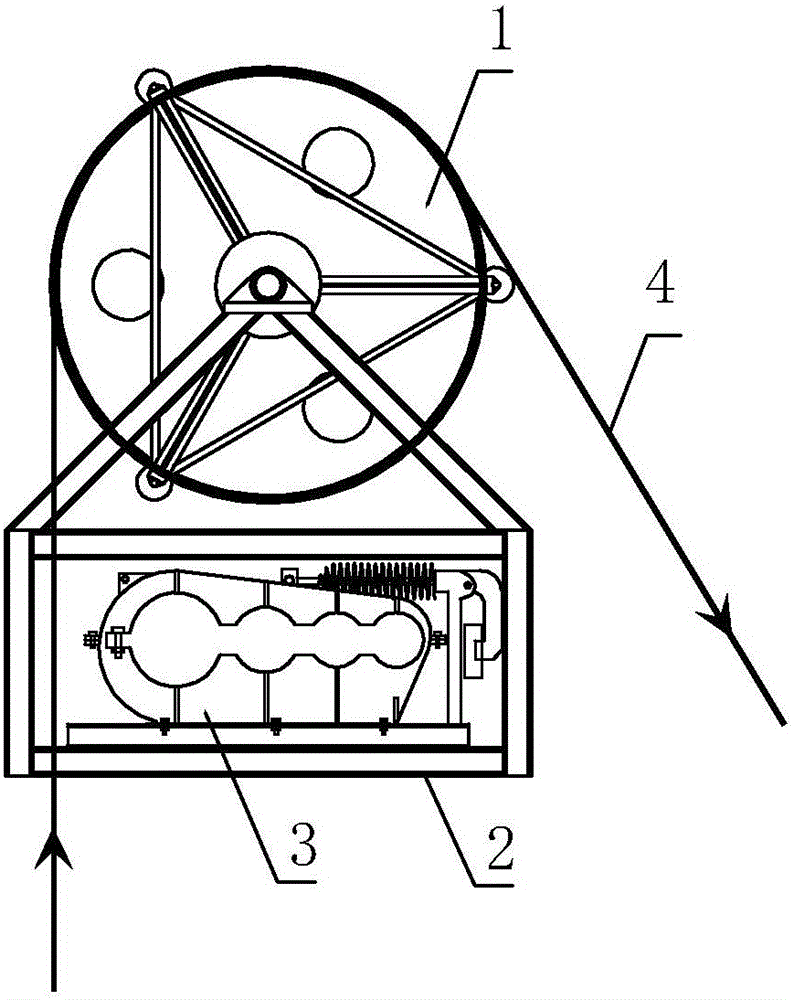

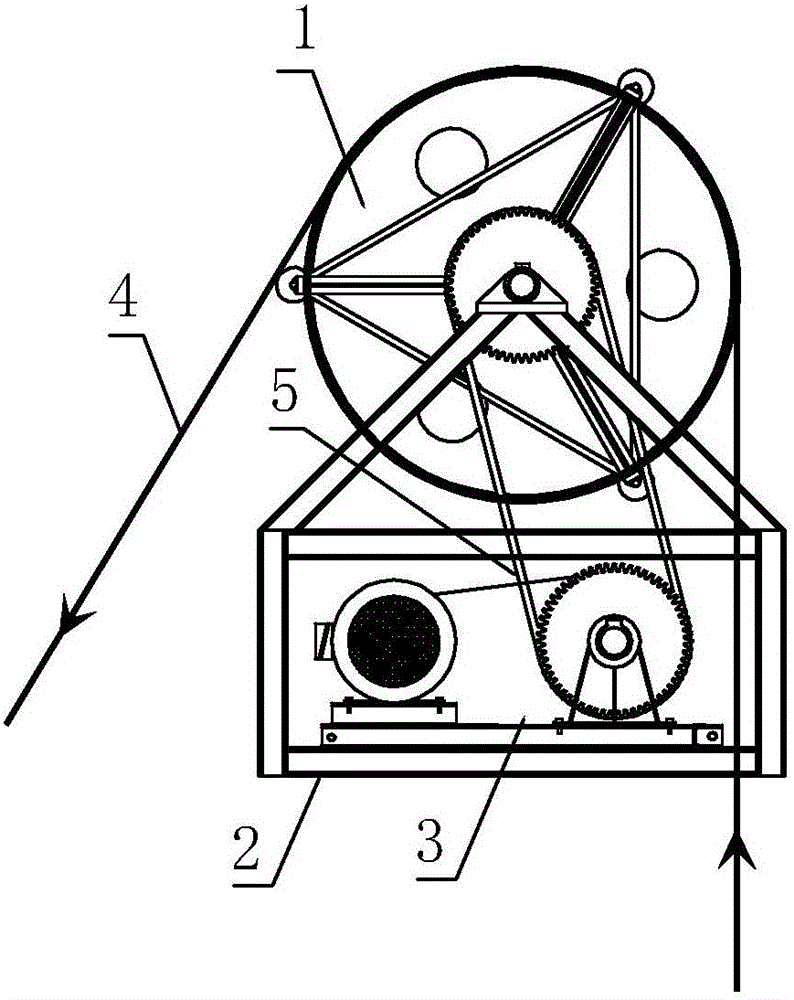

[0044] A steel strand stay cable threading device, such as Figure 1-1 to Figure 1-3 As shown, the steel strand stay cable threading device includes a winch system 1, a stand system 2, a driver 3 and a transmission chain 5;

[0045] Described winch system 1 comprises line distribution disc 11, cylinder 12, connection disc 13, tripod 14, winch gear disc 15 and rotating shaft 16 (see Figure 2-1 to Figure 2-3 ); the main body of the winch system 1 is a circular drum 12, and the rotating shaft 16 passes through the center of the circular drum to drive the drum to rotate. The tripod frame protruding from the top corner is welded on the connection plate 13 on the rotating shaft; the three top corners of the tripod are respectively equipped with a line distribution plate 11, and the line separation plate 11 is composed of six circular steel plates and a The central shaft is composed of; the winch gear plate 15 is installed outside the tripod 14 on one side of the drum and fixed on ...

Embodiment 2

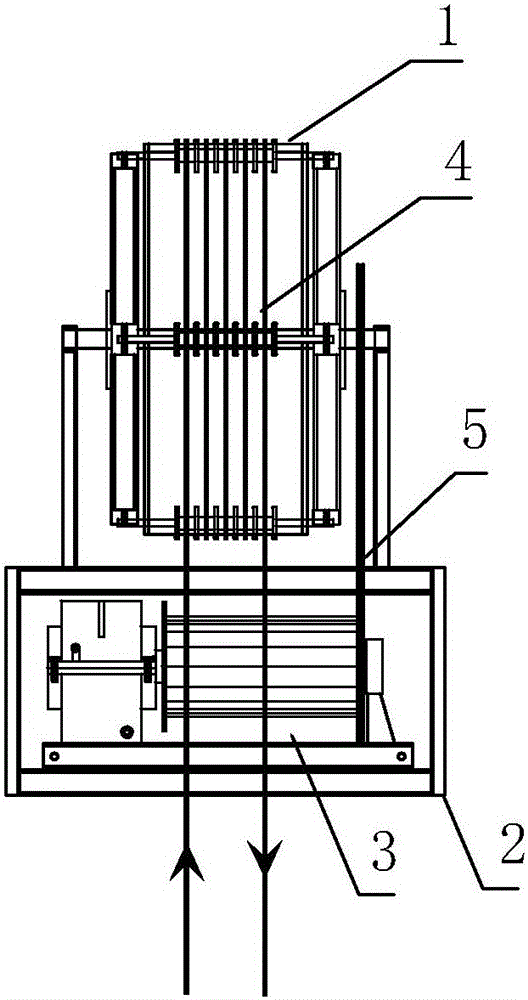

[0049] A cable-threading method for steel strand stay cables of a cable-stayed bridge, the method is to place the entire steel strand stay cables on the main girder end of the bridge, and pull the anchor end of the steel strand stay cables from the cable tray Draw out, utilize the steel strand stay cable threading device described in embodiment one to pull the steel strand stay cable to the main tower end; One side of the drum is introduced, and the steel strand stay cables are sequentially wound on the drum along the splitting disc, and are exported from the other side of the drum to penetrate into the HDPE round pipe, and the cables are threaded from the tower end to the beam end along the inner wall of the round pipe (see Figure 5 ).

[0050] Its specific steps are:

[0051] A. Installation equipment: Arrange the steel strand stay cable threading device on the cantilevered steel frame at the top of the tower;

[0052] B. Pull the steel strand stay cable to the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com