Apparatus and method for collapsible loess combined with lime-soil compaction pile and CFG rigid pile

A technology of lime-soil compaction piles and collapsible loess, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of poor adaptability in local areas, and achieve simple structure, light structure, and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

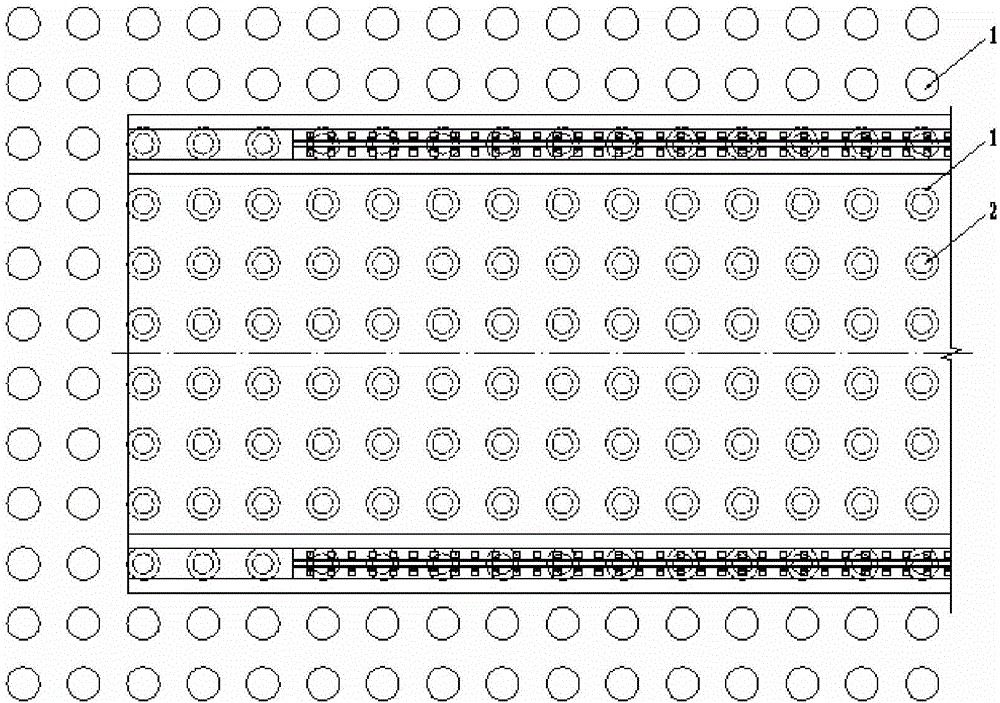

[0022] The device for joint processing of collapsible loess by lime-soil compaction pile and CFG rigid pile of the present invention, its preferred embodiment is:

[0023] It includes a plurality of lime-soil compaction piles arranged in the collapsible loess area to be treated, and a CFG rigid pile is arranged in the pile body of the lime-soil compaction pile, and the pile diameter of the lime-soil compaction pile is larger than the CFG rigid pile pile diameter.

[0024] The lime-soil compaction pile is made of lime-soil filler, and the CFG rigid pile is made of concrete.

[0025] The upper pile body of the CFG rigid pile is provided with a reinforcement mesh.

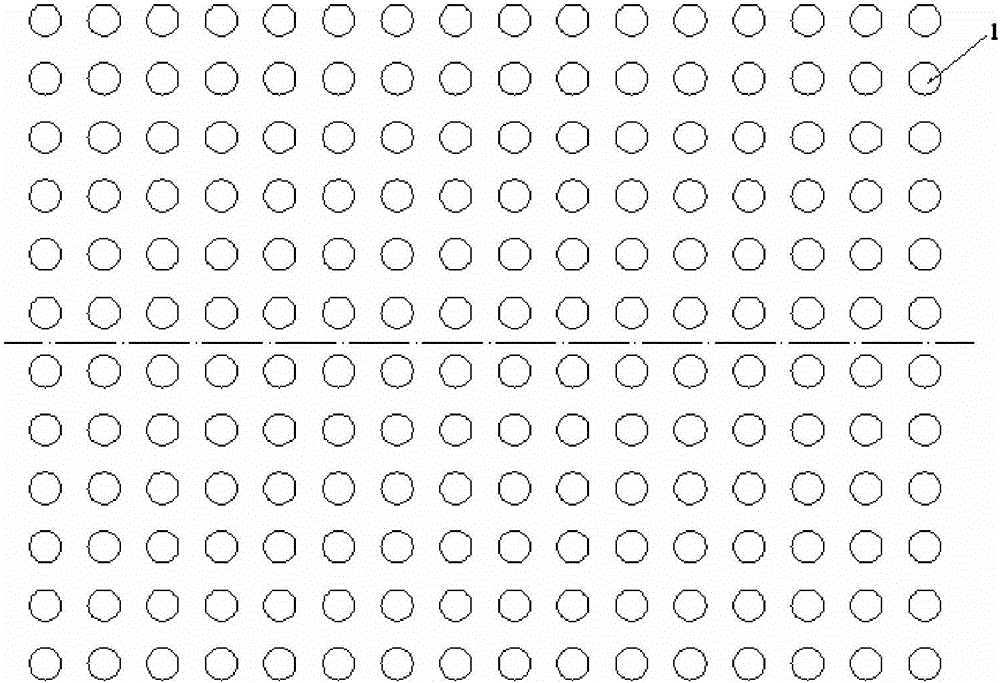

[0026] The pile spacing of the lime-soil compaction piles is greater than or equal to 3 times the pile diameter of the CFG rigid pile.

[0027] The pile bottom of the lime-soil compaction pile is the bottom of the collapsible loess, and the pile bottom of the CFG rigid pile is flush with the pile bottom of the descr...

specific Embodiment

[0039] Such as Figure 1 to Figure 6 Shown:

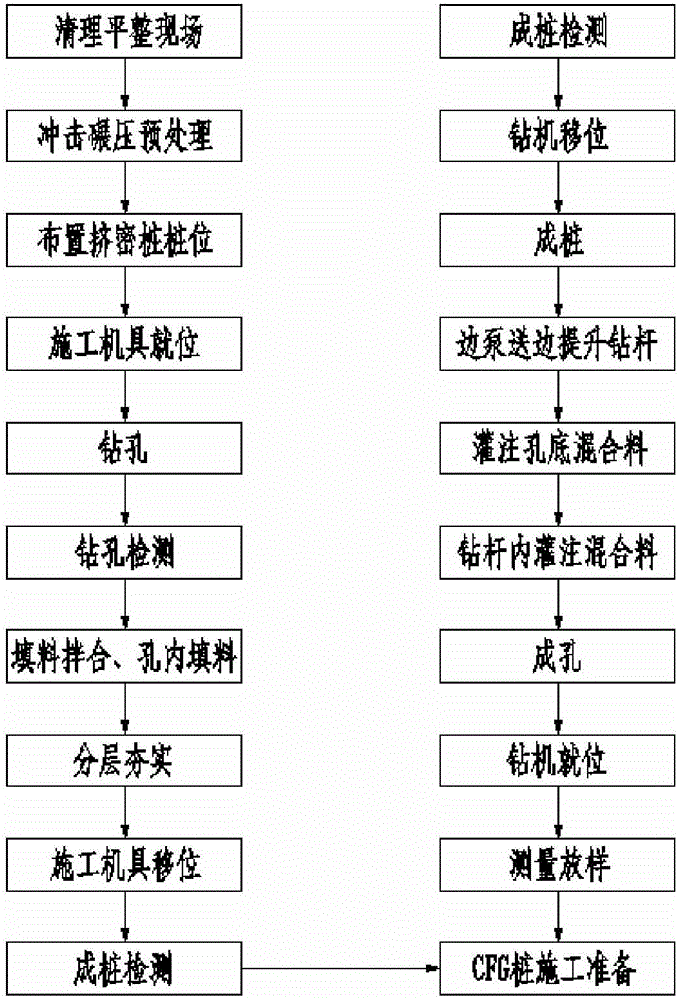

[0040] It includes the following steps: step 1, the foundation of the collapsible loess 1 area to be treated is cleaned and leveled and impact-rolled; The inner filler is punched and rammed in layers with a column hammer to form a compacted pile; step 3, a long auger drill is arranged on the compacted pile 2, and a hole is drilled in the compacted pile body to the design depth of the CFG rigid pile 3, and the mixture is poured into the pile after the hole is formed. CFG rigid pile 3.

[0041] Step 1 includes sub-steps such as cleaning and leveling, impact rolling pretreatment, etc.; Step 2 includes arranging compaction pile positions, placing compaction pile equipment in place, drilling, drilling inspection, filling making and filling in holes, and column hammer division. Sub-steps such as layer ramming, removal of construction equipment, pile detection of compacted piles, etc.; step 3 includes long auger drilling rig in place, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com