Preparation method of multifunctional bamboo engineering material used as light wood structure keel

A multi-functional, wood-structured technology, applied in wood processing equipment, building components, manufacturing tools, etc., can solve the problems of not being effectively used, difficulty in flattening bamboo, and low added value, and achieve density and air porosity. control, speed up the process of localization, and the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

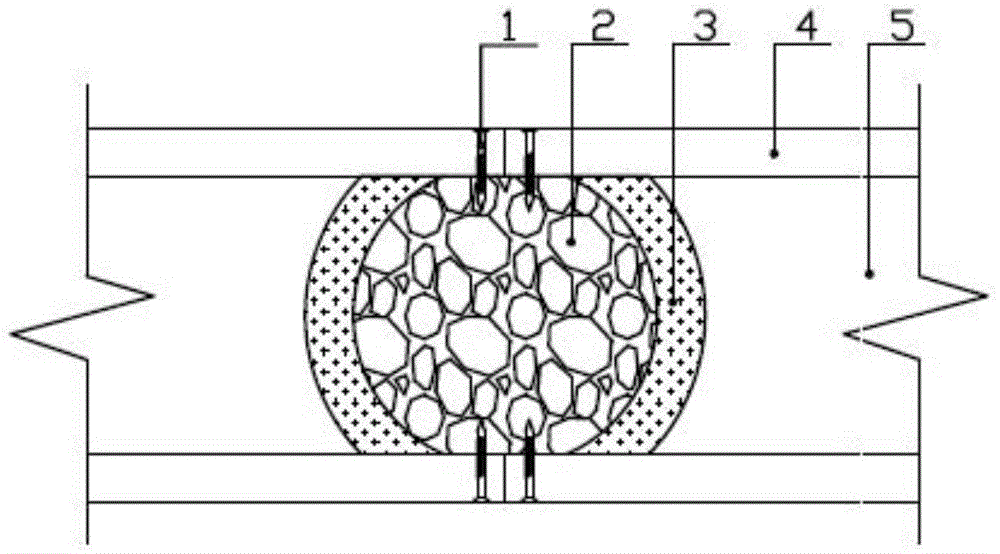

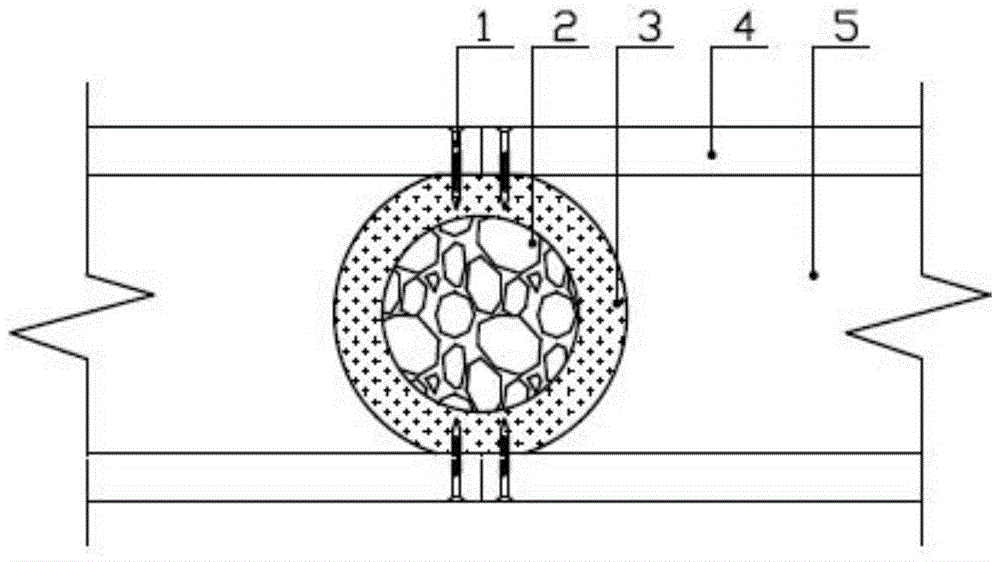

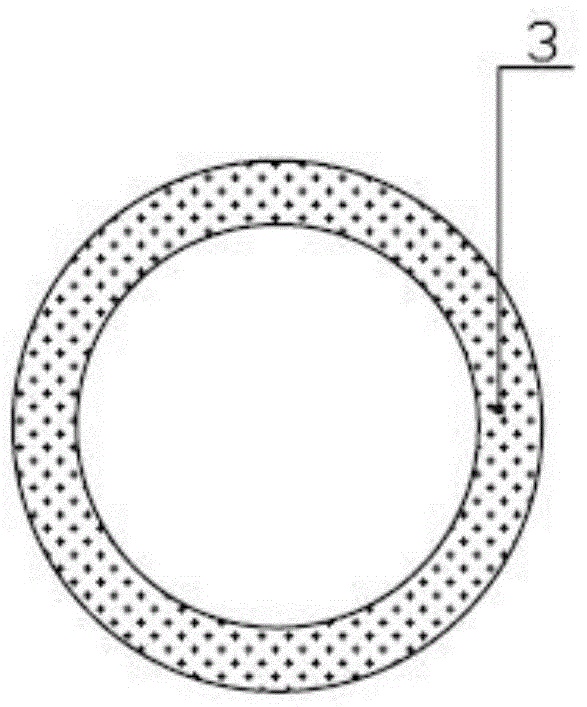

[0028] Such as Figure 1~4 As shown, a multifunctional bamboo engineering material used as a light wood structure keel includes raw bamboo and foaming material 2, and the foaming material 2 is placed inside the raw bamboo, and the raw bamboo is arranged on the wall material , between cladding panels 4 of roofing materials or flooring materials, and are connected by screws 1, the diameter of the original bamboo matches the size of the wall material, roofing material or flooring material, and the gap formed between the original bamboo and cladding panels 4 The heat-insulating and flame-retardant material 5 can be selectively filled. The thickness of the bamboo wall 3 of the original bamboo is in the range of 8 mm to 10 mm.

[0029] The preparation method of the above-mentioned multifunctional bamboo engineering material used as a light wood structure keel comprises the following steps:

[0030] (1) Raw material preparation: prepare raw bamboo that matches the size of the wall ...

Embodiment 2

[0037] The preparation method of the above-mentioned multifunctional bamboo engineering material used as a light wood structure keel comprises the following steps:

[0038] (1) Raw material preparation: prepare raw bamboo that matches the size of the floor material, foam adhesive, and 100-mesh wood processing waste;

[0039] (2) Raw bamboo pre-processing: After removing the inner bamboo compartment of the raw bamboo, control its moisture content within the range of 15% to 20%;

[0040] (3) Foaming material preparation: Add wood processing waste to the foaming adhesive in a proportion of 70% by mass, mix evenly, place inside the original bamboo and perform foaming treatment;

[0041] (4) Preparation of bamboo engineering materials: size processing is carried out on raw bamboo filled with foaming materials, and engineering materials with equal width along its length direction are processed.

[0042] Determine and select the original bamboo with a suitable length range according...

Embodiment 3

[0045] The preparation method of the above-mentioned multifunctional bamboo engineering material used as a light wood structure keel comprises the following steps:

[0046](1) Raw material preparation: prepare raw bamboo that matches the size of the roofing material, foaming adhesive, and 70-mesh wood processing waste;

[0047] (2) Raw bamboo pre-processing: After removing the inner bamboo compartment of the raw bamboo, control its moisture content within the range of 12% to 16%;

[0048] (3) Foaming material preparation: Add wood processing waste to the foaming adhesive in a proportion of 50% by mass, mix evenly, place inside the original bamboo and perform foaming treatment;

[0049] (4) Preparation of bamboo engineering materials: The original bamboo filled with foam material is processed to size, and engineering materials with equal width along its length direction are processed.

[0050] According to the size of the roofing material, determine and select the original bam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com