End soil mass reinforcement system and method

A soil reinforcement and tip technology, which is used in earth-moving drilling, sheet pile walls, mining equipment, etc., can solve the problems of difficult grouting pressure, high cost and great harm, and achieve good reinforcement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

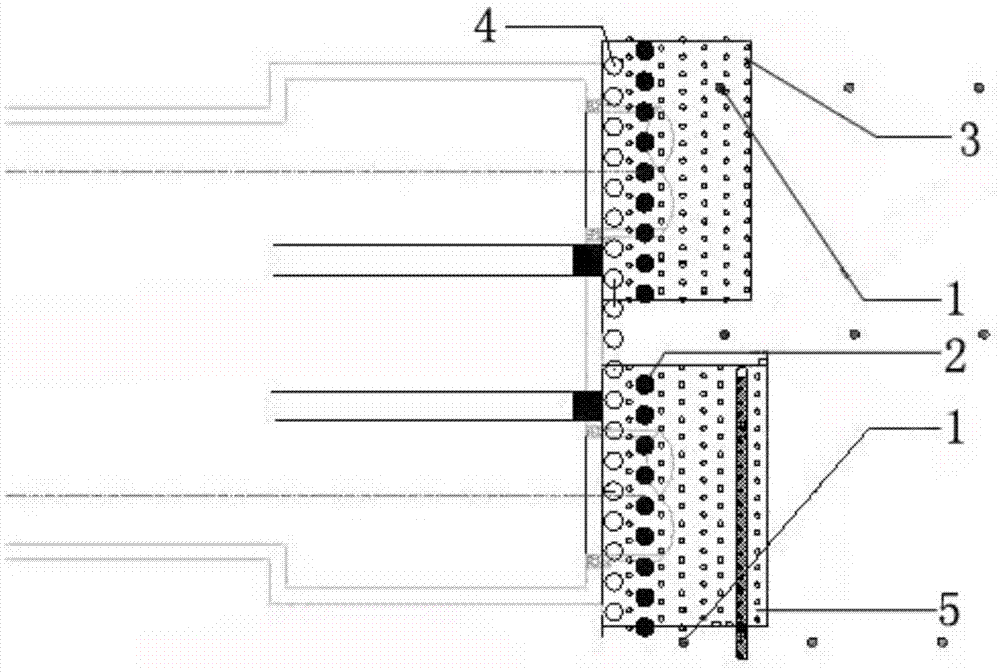

[0030] As shown in the figure, a soil reinforcement system at the end, a soil reinforcement system at the end, includes the shield starting, the receiving end grouting reinforcement area and the structural surrounding piles, and also includes the laying at the shield starting end Dewatering wells outside the grouting reinforcement zone.

[0031] The system also includes plain concrete piles arranged outside the edges of the structure enclosure piles at the entrance of the construction opening.

[0032] The inner diameter of the dewatering well is 300-400mm, the well depth is 25-31m, and the spacing is 6-8m.

[0033] The concrete piles are arranged 0.5 meters outside the edge of the structure enclosure piles, with a distance of 1000-1400mm.

[0034] A method for reinforcing soil at an end, comprising the steps of:

[0035] Grouting reinforcement, layout of dewatering wells, pumping of dewatering wells, reinforcement of plain concrete piles, inspection of soil reinforcement ef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com