Numerically controlled tool cutting edge measuring method based on laser scanning confocal technology

A technology of laser scanning and measurement method, applied in the field of measurement, can solve the problems of low precision and poor economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0055] Such as Figure 1-6 shown.

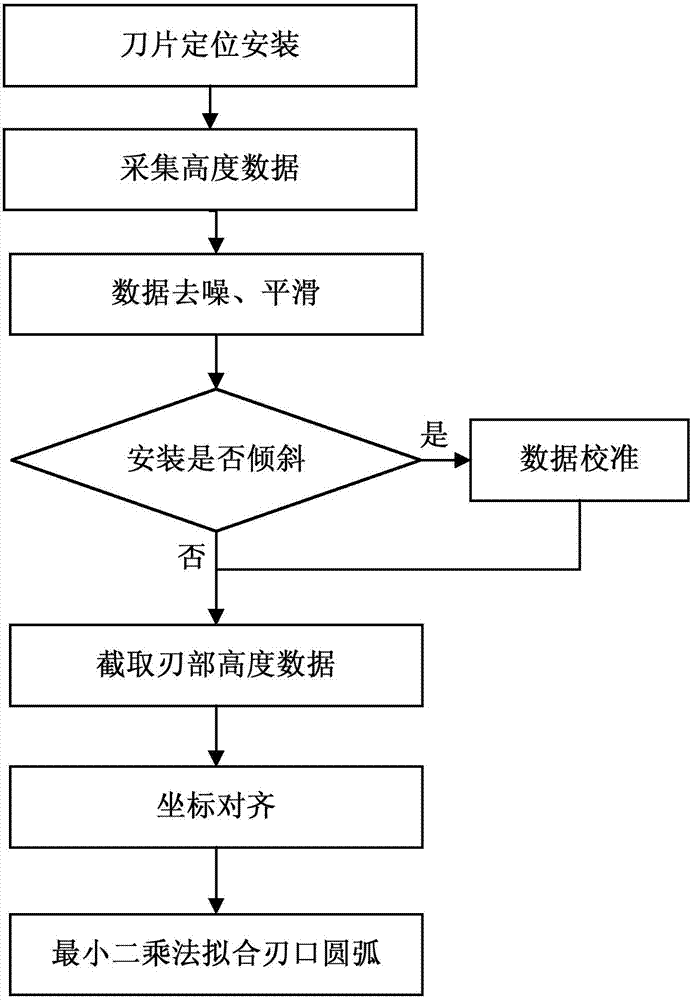

[0056] A CNC tool edge radius measurement method based on laser scanning confocal technology, which includes tool edge preprocessing, tool installation, tool edge data acquisition, and data postprocessing, such as image 3 shown. in:

[0057] (1) The pretreatment of the cutting edge refers to cleaning the cutting edge, removing the residual debris of the cutting edge after sharpening, and ensuring the measurement accuracy. During specific implementation, acetone reagent is added in the ultrasonic vibration cleaning machine, and the cutter is put into it for cleaning for 10 minutes.

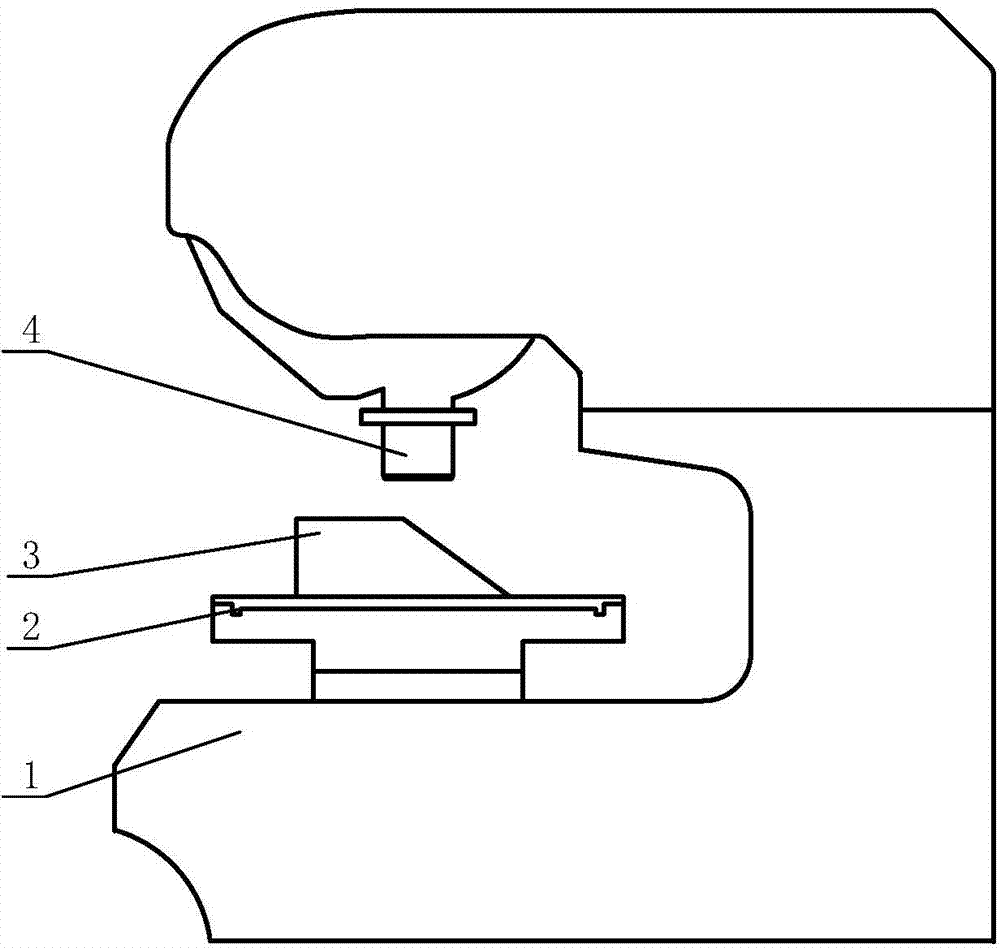

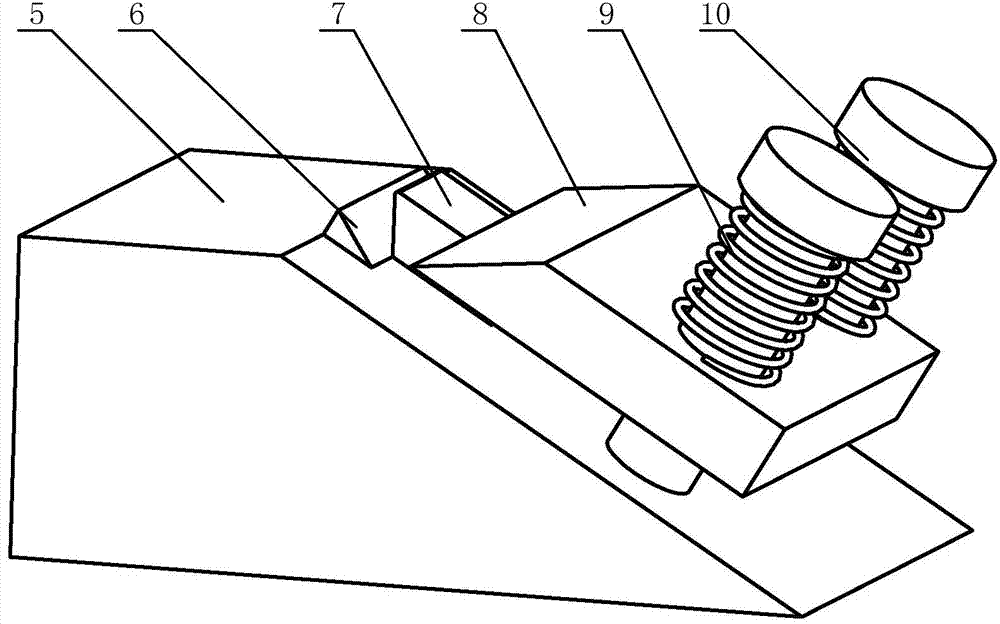

[0058] (2) The installation of the tool refers to selecting the gauge block with a suitable angle, and installing the tool correctly to the figure 2 On the jig shown, the jig is mounted on the figure 1 On the measuring device shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com