Ultrasonic atomization plasma processing device

A plasma and processing device technology, which is applied in the field of ion plasma processing devices, can solve problems such as uneven processing, and achieve the effect of uniform processing and easy diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

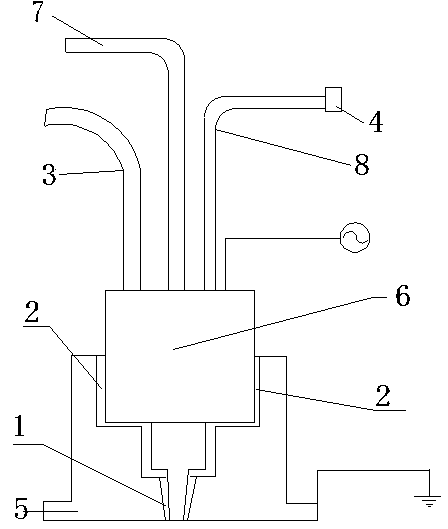

[0018] Such as figure 1 As shown, an ultrasonic atomization plasma processing device includes a power supply, an ultrasonic transducer 6, an ultrasonic nozzle 1 and an electrode seat 5. The ultrasonic transducer 6 is provided with a vent hole, and the vent hole is connected to the vent pipe 7. The ultrasonic transducer There is also a liquid injection hole in the energy device, the liquid injection hole is connected to the liquid pipe 8, the ultrasonic nozzle 1 is connected to the bottom of the electrode seat 5, and the ultrasonic transducer 6 and the ultrasonic nozzle 1 are connected to each other, and the ultrasonic transducer 6 is connected to the ultrasonic nozzle 1. The ultrasonic nozzle 1 is set on the electrode holder 5, the ultrasonic transducer 6 is connected to the positive pole of the high-frequency power supply, the frequency range of the high-frequency power supply is 10Khz-100Khz, the electrode holder 5 is grounded, the ultrasonic transducer 6 and the ultrasonic n...

Embodiment 2

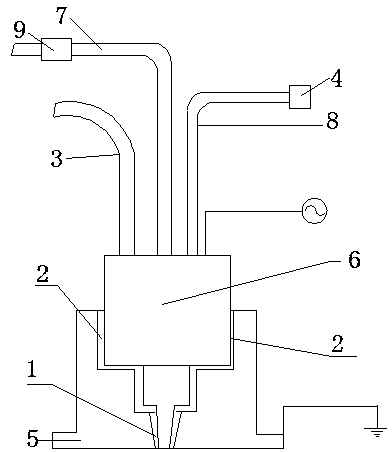

[0021] The rest are the same as in Embodiment 1, except that a flow regulating valve 9 is provided on the ventilation pipe to control the flow rate of the gas, and the flow regulating valve 9 can effectively adjust the flow rate of the gas entering. Avoid passing too much gas so that the gas discharge effect is weakened, or avoid passing too little gas so that too little plasma can not effectively treat the material to be processed.

[0022] The beneficial effects of the present invention are: the present invention uses the ultrasonic transducer as one electrode of the plasma, and the electrode seat as the other electrode, an electric field is generated between the electrode seat and the ultrasonic converter, and liquid and gas are injected into the ultrasonic transducer Plasma is generated by electric field discharge, and the incoming liquid is atomized by ultrasonic waves and sprayed out through ultrasonic nozzles. Ultrasonic transducers can convert electrical energy into vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com