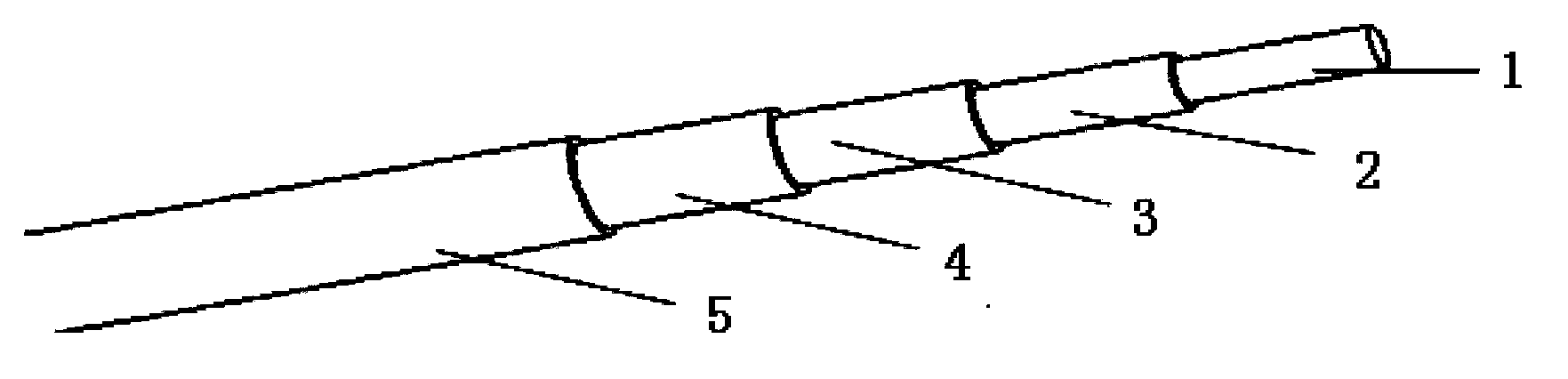

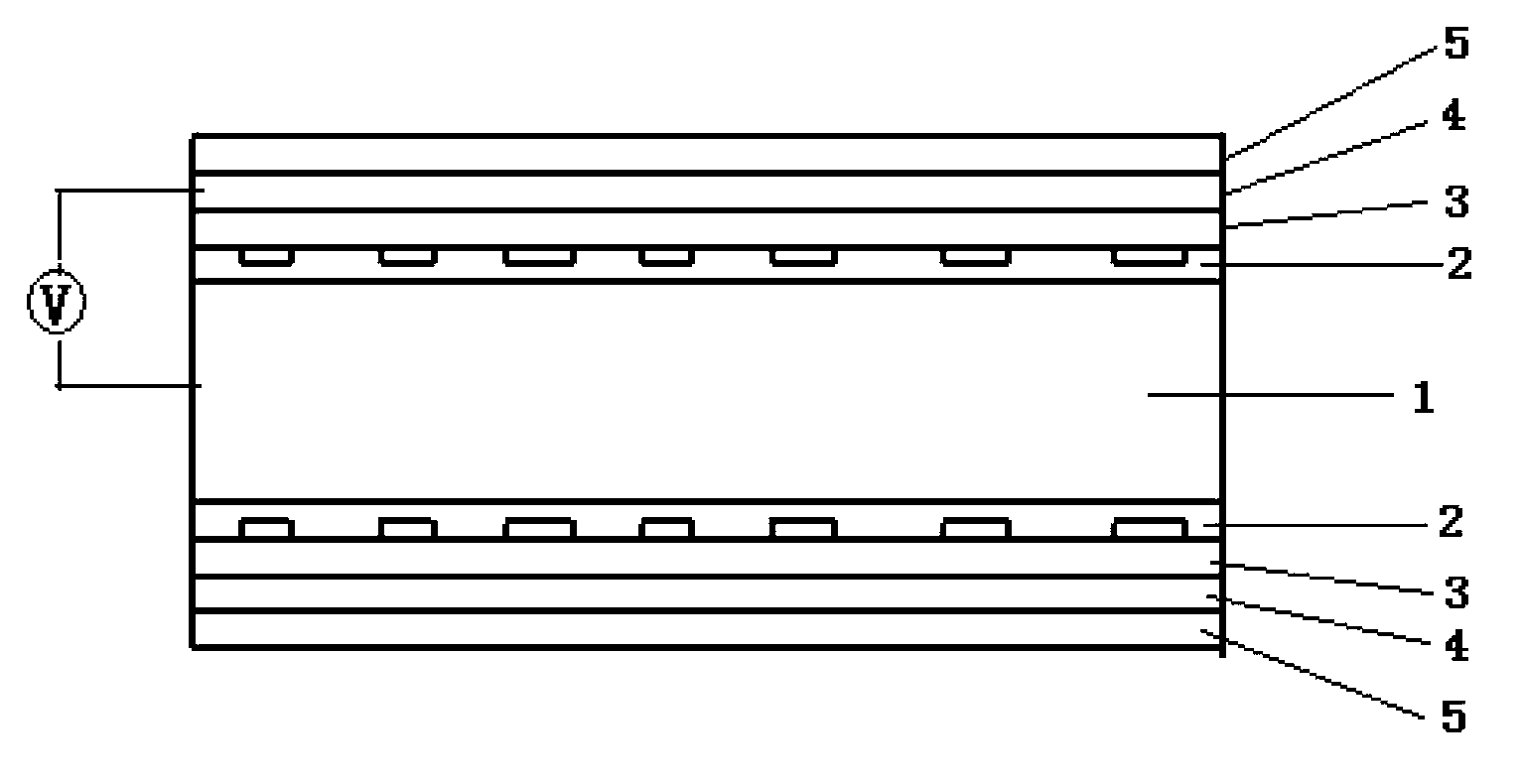

Electret piezoelectric cable and applications thereof

A technology of piezoelectric cables and electrets, which is applied to piezoelectric/electrostrictive/magnetostrictive devices, parts and circuits of piezoelectric devices or electrostrictive devices, and can solve problems such as weak signal strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1 is used as the preparation of the cable of traffic axis sensor

[0055] a. Preparation of thin film for piezoelectric electret layer:

[0056] Put 10g of PVDF into a 1000mL beaker, use a 100mL graduated cylinder to measure 80ml of dimethylformamide (DMF) into the beaker to dissolve PVDF (11.7wt%), then seal the beaker with plastic wrap and ultrasonically treat it for 30min. The PVDF is completely dissolved and ready for later use.

[0057] The above prepared PVDF solution is evenly and directly coated on the prepared PDMS soft template with cuboid protrusions by spin coating (the height of the raised cuboid of the template is 9 microns, and the bottom surface is a square with a side length of 9 microns, The interval between the protrusions is 0.5 μm), and the coating is controlled so that the thickness of the PVDF film after drying is 100 μm. After coating, it is placed in a vacuum dryer at 80° C. for 1 hour. After drying, the PDMS soft template was remov...

Embodiment 2

[0066] Embodiment 2 is used as the preparation of the cable of traffic axis sensor

[0067] a. Preparation of thin film for piezoelectric electret layer:

[0068] Put 10g of PVDF into a 1000mL beaker, use a 100mL graduated cylinder to measure 80ml of dimethylformamide (DMF) and add it to the beaker to dissolve PVDF (11.7wt%), then seal the beaker with plastic wrap and ultrasonically treat it for 30min. The PVDF is completely dissolved and ready for later use.

[0069] The above prepared PVDF solution is evenly and directly coated on the prepared PDMS soft template with cuboid protrusions by spin coating (the height of the raised cuboid of the template is 0.5 micron, and the bottom surface is a square with a side length of 1 micron, The interval between the protrusions is 15 microns), and the coating is controlled so that the thickness of the PVDF film after drying is 100 microns. After coating, it is placed in a vacuum dryer at 80° C. for 1 hour. After drying, the PDMS soft ...

Embodiment 3

[0078] Embodiment 3 is used as the preparation of the cable of traffic axis sensor

[0079] a. Preparation of thin film for piezoelectric electret layer:

[0080] Put 10g of PVDF into a 1000mL beaker, use a 100mL graduated cylinder to measure 80ml of dimethylformamide (DMF) into the beaker to dissolve PVDF (11.7wt%), then seal the beaker with plastic wrap and ultrasonically treat it for 30min. The PVDF is completely dissolved and ready for later use.

[0081] The above prepared PVDF solution is evenly and directly coated on the prepared PDMS soft template with cuboid protrusions by spin coating (the height of the raised cuboid of the template is 5 microns, and the bottom surface is a square with a side length of 5 microns, The interval between the protrusions is 50 microns), and the coating is controlled so that the thickness of the PVDF film after drying is 100 microns. After coating, it is placed in a vacuum dryer at 80° C. for 1 hour. After drying, the PDMS soft template wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com