Novel two-section type seven-phase permanent magnet fault-tolerant motor

A permanent magnet fault-tolerant, motor technology, applied in the direction of electrical components, electromechanical devices, etc., can solve problems such as poor fault isolation capability, affecting system fault tolerance, system redundancy mutual interference, etc., to reduce torque ripple, improve fault tolerance, The effect of good physical isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

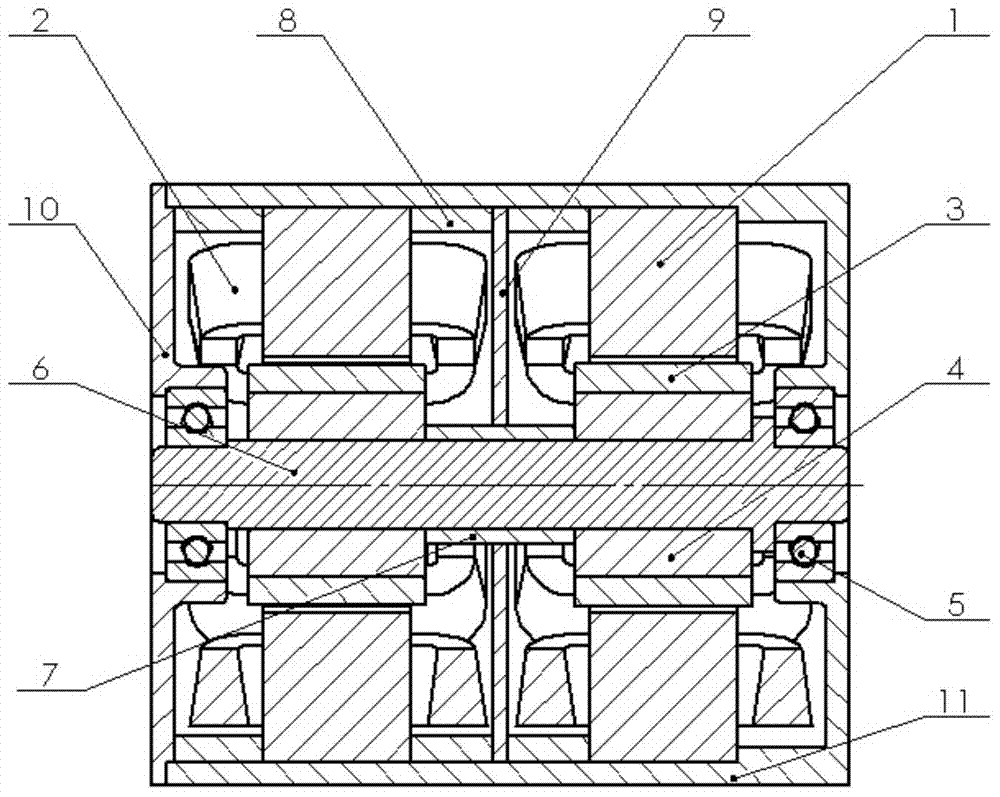

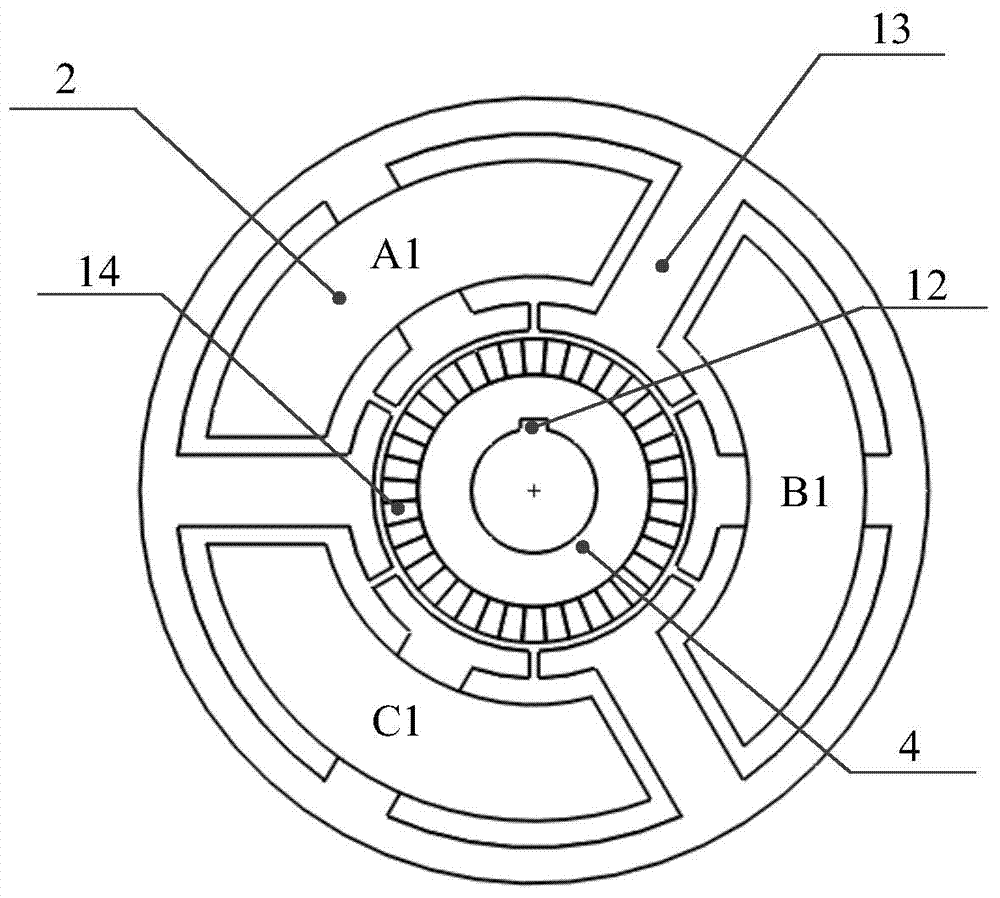

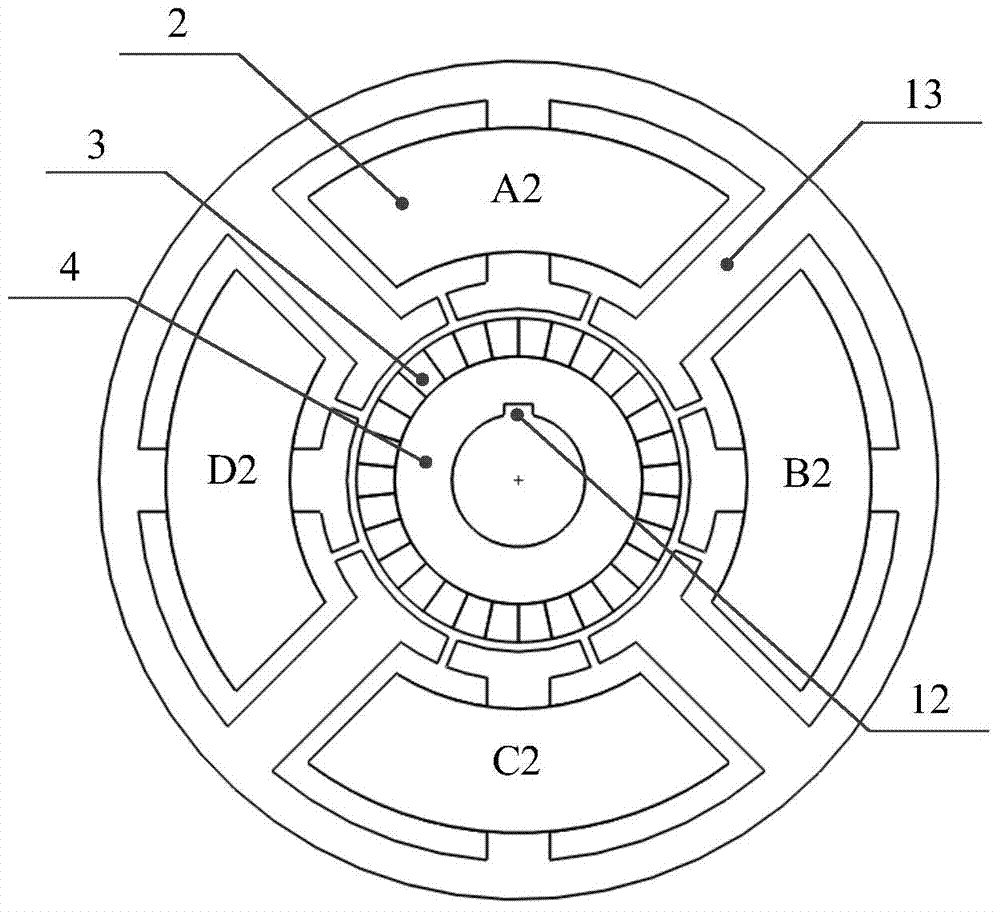

[0023] Such as figure 1 As shown, the new two-stage seven-phase permanent magnet fault-tolerant motor provided by the present invention adopts a coaxial two-stage structure, including: two coaxial series stator assemblies, two rotor assemblies, bearings 5, rotating shafts 6, bushings Cover 7, insulating sleeve 8, magnetic isolation plate 9, end cover 10 and casing 11. The stator assembly includes a stator core 1 and a stator winding 2 . The rotor assembly includes a Halbach structure permanent magnet 3 and a rotor core 4 .

[0024] The two stator assemblies and the two rotor assemblies are coaxially installed in the same housing, wherein the first stator assembly and the first rotor assembly form a three-phase permanent magnet fault-tolerant motor segment, and the second stator assembly and the second rotor assembly form a four-phase permane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com