Rotary type electrostatic generating device

A power generation device and rotary technology, applied in the direction of friction generators, etc., can solve the problems of complex structure and unfavorable packaging, and achieve the effects of small size, low rotational resistance and high energy conversion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 Turntable electrostatic generator

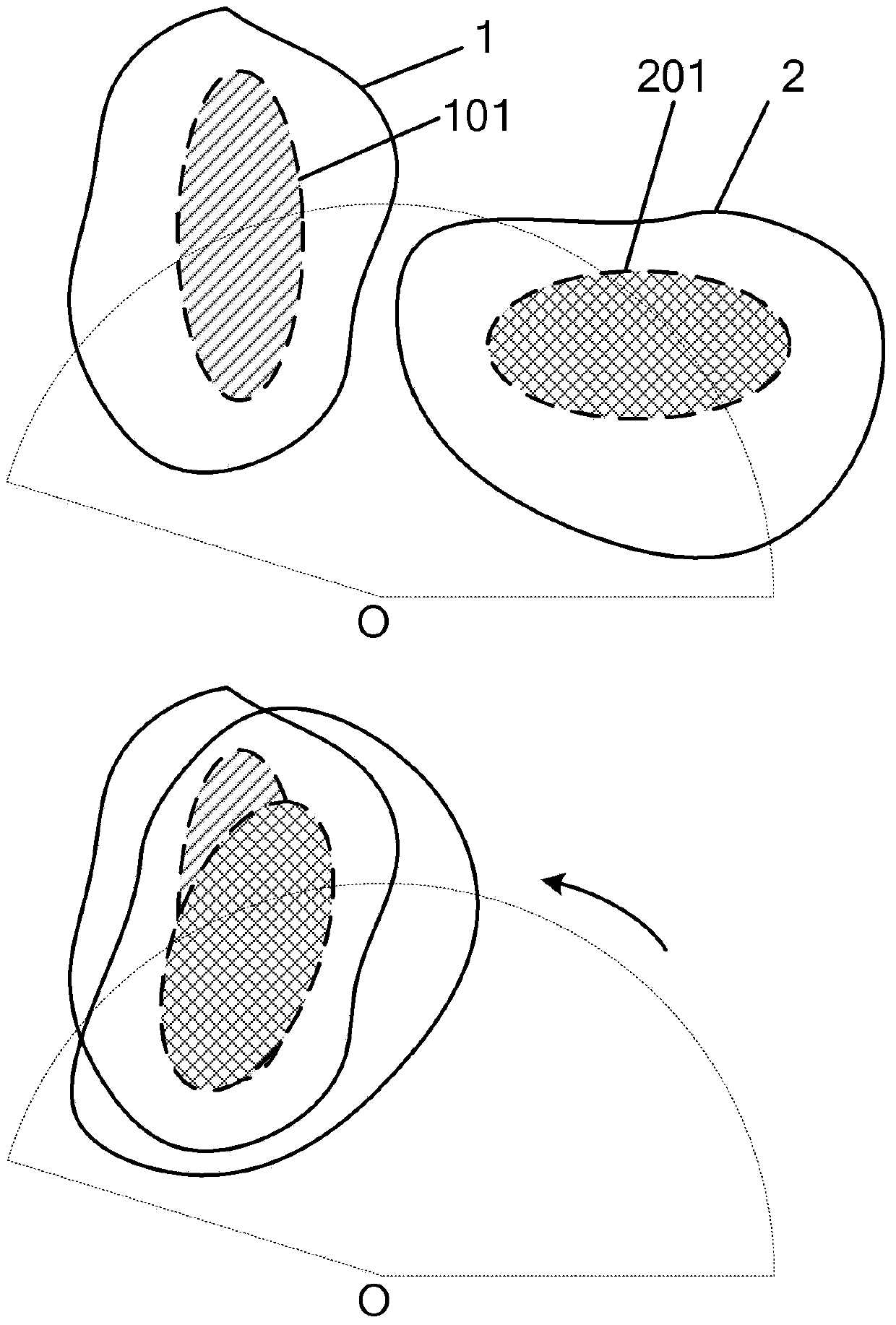

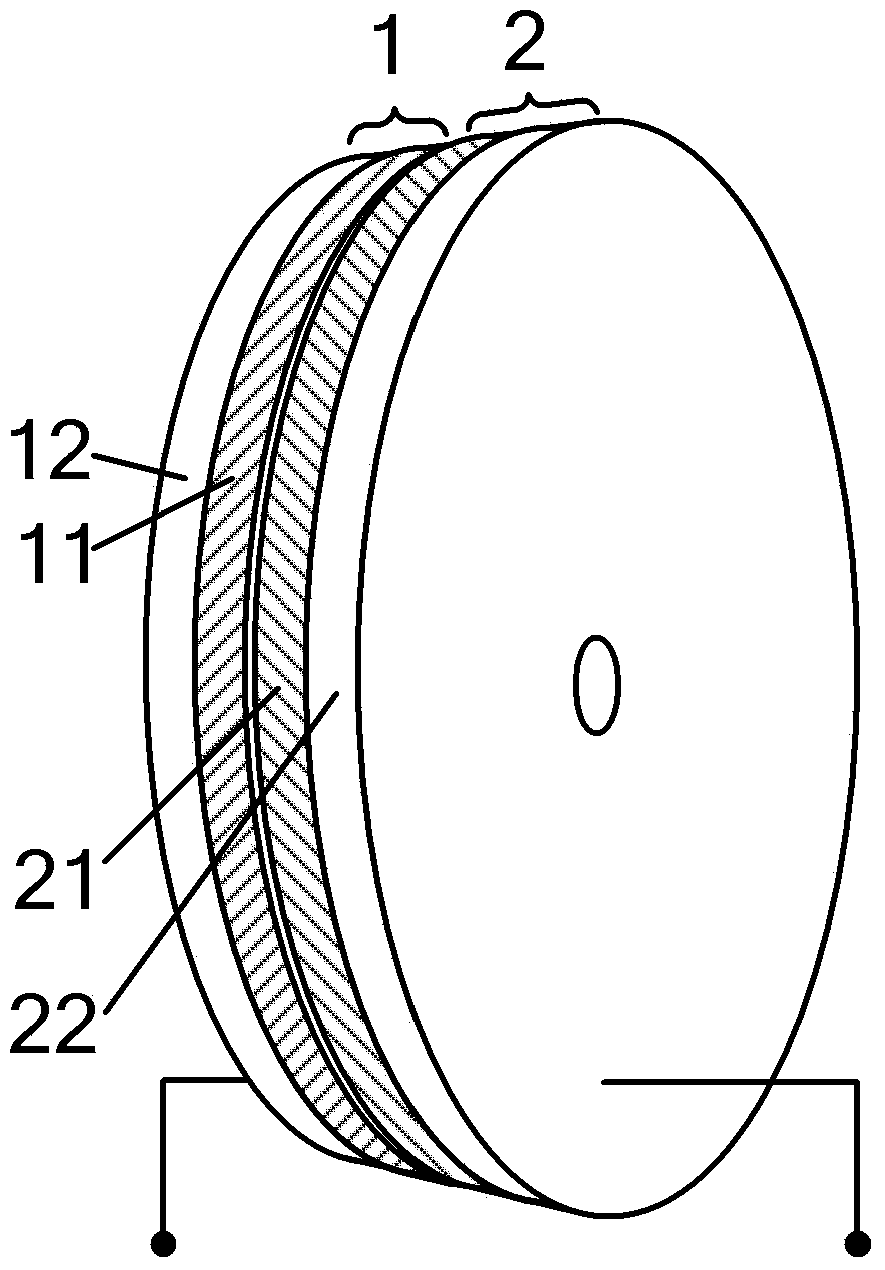

[0053] The first embodiment is a rotating disc type electrostatic generator, image 3 It shows its schematic structure diagram, such as image 3 As shown, it includes two turntables, that is, a first turntable 1 and a second turntable 2, both of which are in the shape of a pie and have the same outer diameter. Also, the two turntables coincide with each other in a center-aligned manner,

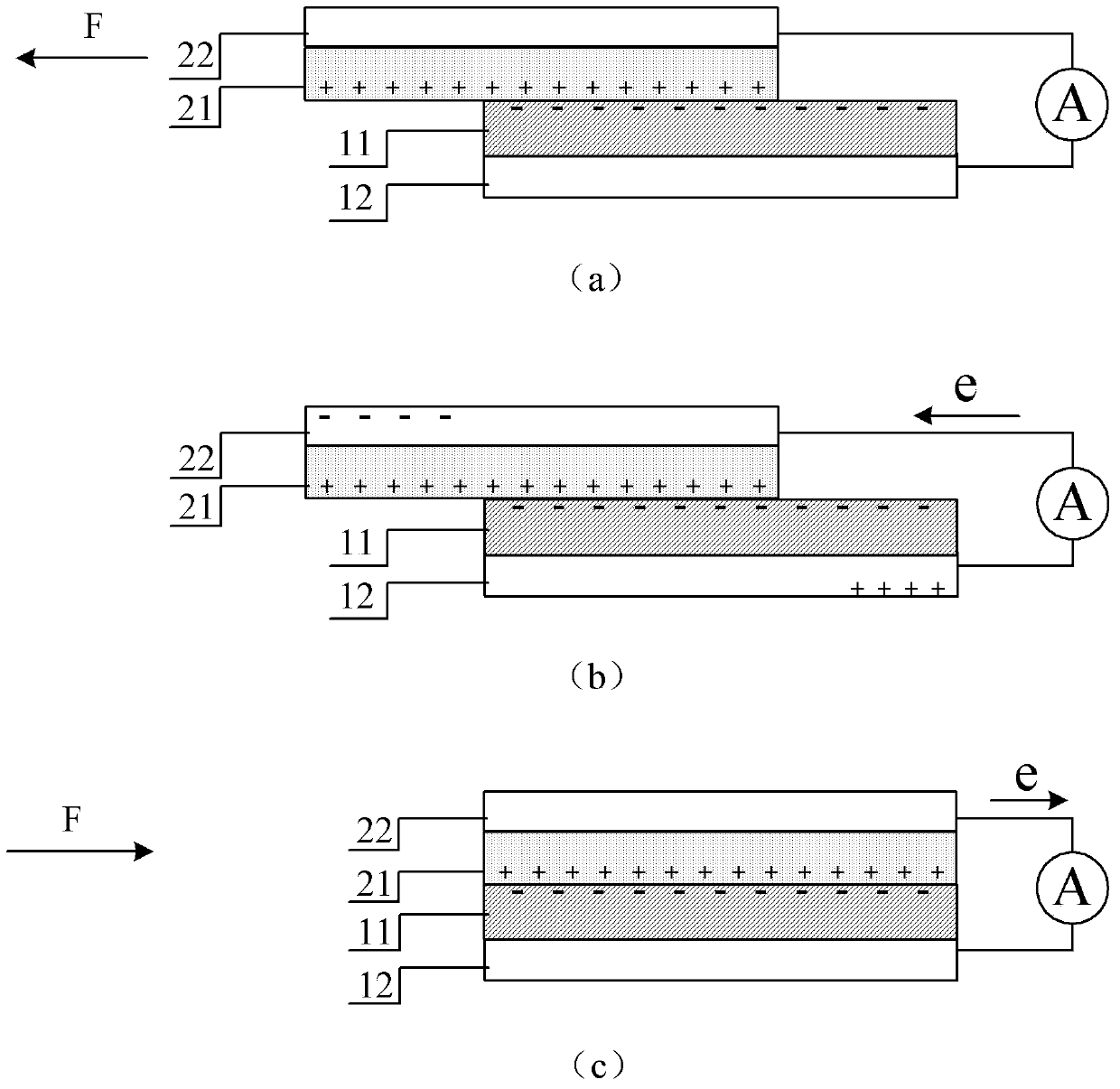

[0054] The first turntable 1 and the second turntable 2 can rotate relatively around their central axis (rotate simultaneously, or one is stationary and the other rotates), and relative sliding can occur on their contact surfaces during rotation. The contact surfaces of the two turntables both include friction layers, shown as a first friction layer 11 and a second friction layer 21 in the figure. The surfaces of the first friction layer 11 and the second friction layer 21 are respectively provided with friction material regions 101 a...

Embodiment 2

[0076] Embodiment two: wind energy generator

[0077] The second embodiment is a wind energy invention machine constructed by using the rotary disk type electrostatic generator, which can be used to collect wind energy and convert it into electrical energy. Figure 9 A schematic block diagram of the wind energy generator is shown. Such as Figure 9 As shown, the generator utilizes the image 3 The rotating disk type electrostatic generator of the first embodiment shown, and the generator includes a windmill 3, the windmill 3 is fixedly connected with a rotating shaft 4; and, the rotating disk 1 is fixed to a fixing device 5, and the rotating shaft 4 is fixedly connected to the center position of the turntable 2. Thus, when the windmill 3 rotates under the drive of the external wind, it can drive the turntable 2 to rotate relative to the turntable 1 through the rotation shaft, thereby generating an alternating induced potential between the turntable 1 and the turntable 2 to ge...

Embodiment 3

[0079] Embodiment 3: brake energy storage device

[0080] Embodiment 3 is an implementation manner in which the rotary disc type electrostatic generator is applied to a vehicle, such as a brake system of an automobile. During the braking process of the brake pads of existing automobiles, the mechanical energy transformed by the huge frictional force is mostly emitted in the form of heat energy, and has not been utilized. If the turntable electrostatic power generation device of the present invention can be loaded into the brake parts of the brake system, and the mechanical energy of the wheel rotation during the collection is collected, the energy efficiency of the car will be greatly improved, and it will be beneficial to the further development of the composite car and the clean energy car. has great significance.

[0081] Figure 11 A schematic structural diagram of the brake energy storage device of the third embodiment is shown. Such as Figure 11 As shown, the turnta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com