Maximum brightness enhancement module, thyristor dimming led drive circuit and system

A technology of LED driving and maximum brightness, applied in the direction of lamp circuit layout, light source, electric light source, etc., can solve the problems of loss of LED drive circuit efficiency, temperature rise, high power consumption, etc., to improve efficiency and system reliability, and improve the maximum The effect of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

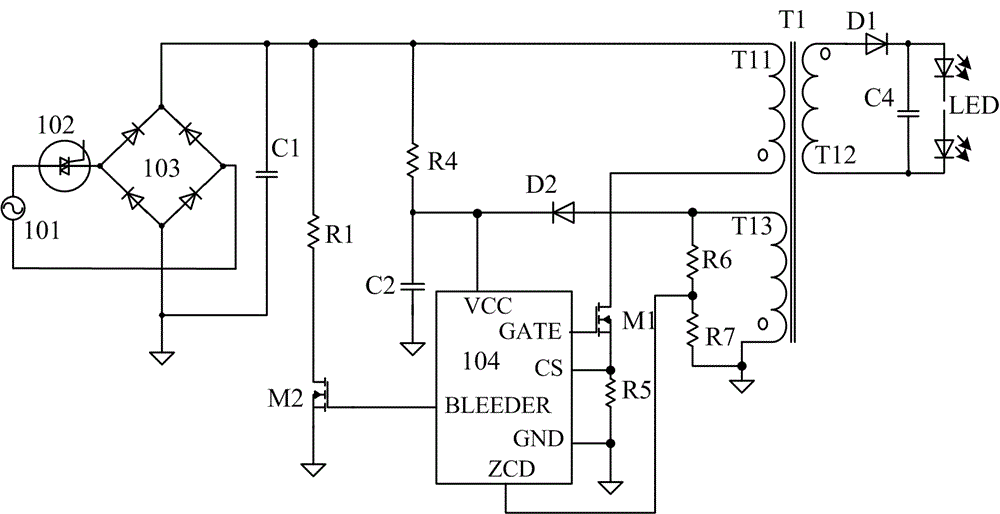

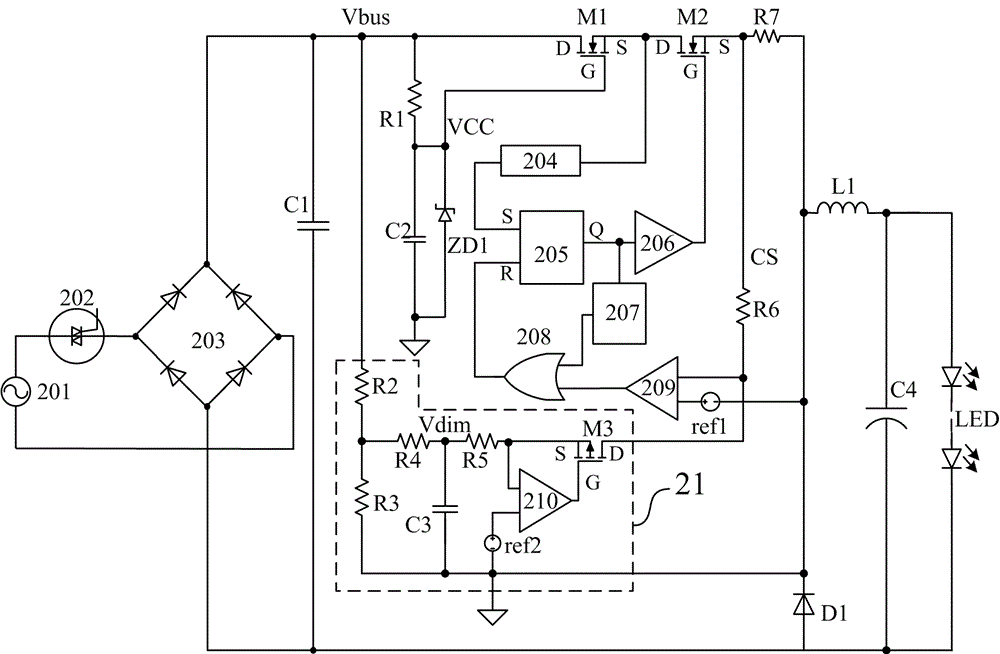

[0018] The implementation of the thyristor dimming LED drive circuit and system provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

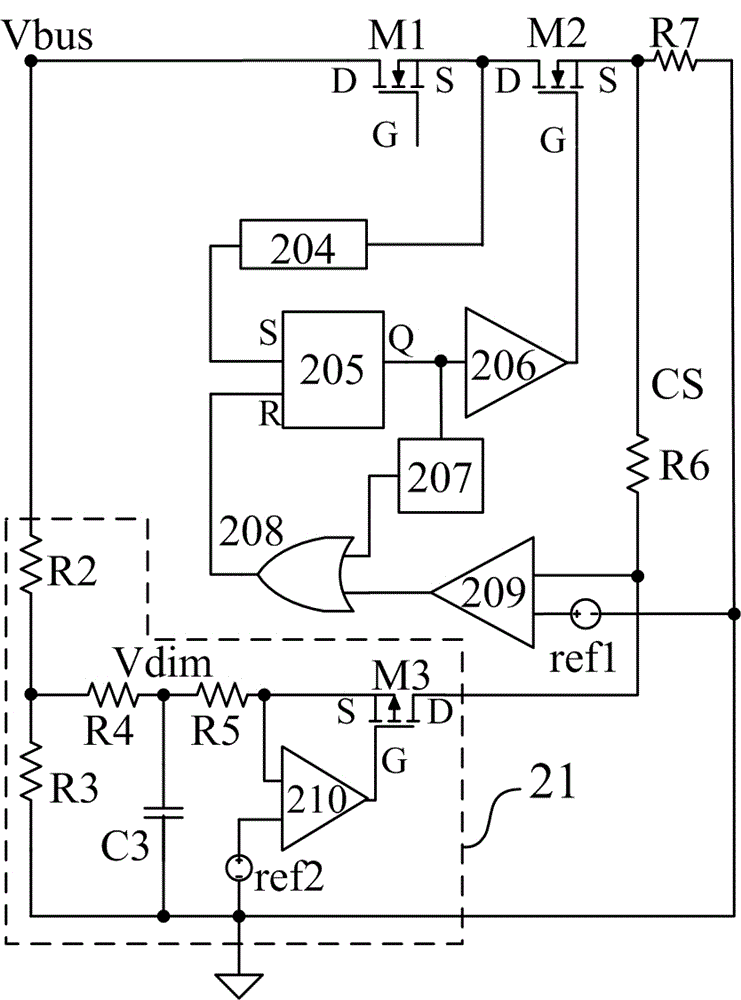

[0019] refer to figure 2 , a structural schematic diagram of the thyristor dimming LED drive circuit according to the present invention, the drive circuit includes: a second MOS transistor M2, a peak current comparator 209, a feedforward resistor R6, a reference voltage source ref1 and A maximum brightness enhancement module 21 .

[0020] The maximum brightness enhancement module 21 includes: an operational amplifier 210, a first MOS transistor M3, a reference voltage source ref2, a voltage division processing unit and a filter unit.

[0021] The voltage division processing unit receives and processes an external voltage signal Vbus with a positive amplitude. As a preferred embodiment, the voltage division processing unit includes an upper voltage divider resistor R2 and a lower v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com