polycarbonate resin composition

A technology of polycarbonate resin and styrene resin, applied in the field of polycarbonate resin compositions with improved chemical resistance and solvent resistance, to achieve improved chemical resistance and solvent resistance, excellent impact resistance , The effect of suppressing cracks (cracks)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Hereinafter, the present invention will be illustrated using examples, but it is not intended to limit the present invention. In addition, parts and % are based on weight unless otherwise indicated.

[0059] The compounding components used are as follows.

[0060] (1) Polycarbonate resin (A):

[0061] Polycarbonate resin synthesized from bisphenol A and phosgene (Calibre-200-20 manufactured by Sumika Styron Polycarbonate Co., Ltd., viscosity average molecular weight: 19,000, hereinafter referred to as "PC")

[0062] (2) Polybutylene terephthalate resin:

[0063] 600FP manufactured by Polyplastics Corporation (hereinafter referred to as "PBT")

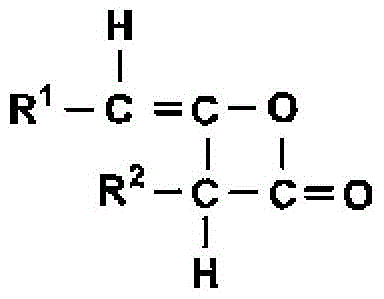

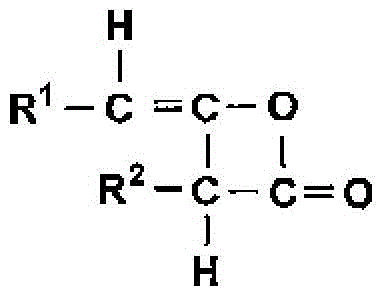

[0064] (3) Alkyl ketene dimer (B):

[0065] AKD1840 manufactured by Eternal Chemical Co., Ltd. (hereinafter referred to as "AKD")

[0066] (4) Rubber-reinforced styrenic resin (C):

[0067] Bulk polymerization ABS resin (Santac AT05 manufactured by Japan A&L Corporation, rubber content: 20%, hereinafter referred to as "ABS"...

PUM

| Property | Measurement | Unit |

|---|---|---|

| visible light transmittance | aaaaa | aaaaa |

| impact toughness | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com