A light and heavy phase redistribution device for a liquid-liquid extraction packed tower

A packed tower and redistribution technology, applied in the direction of liquid solution solvent extraction, etc., can solve the problems of poor uniform distribution effect, high cost, lack of theoretical basis, etc., so as to improve product purity and yield, save space in the tower, and increase transmission capacity. qualitative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

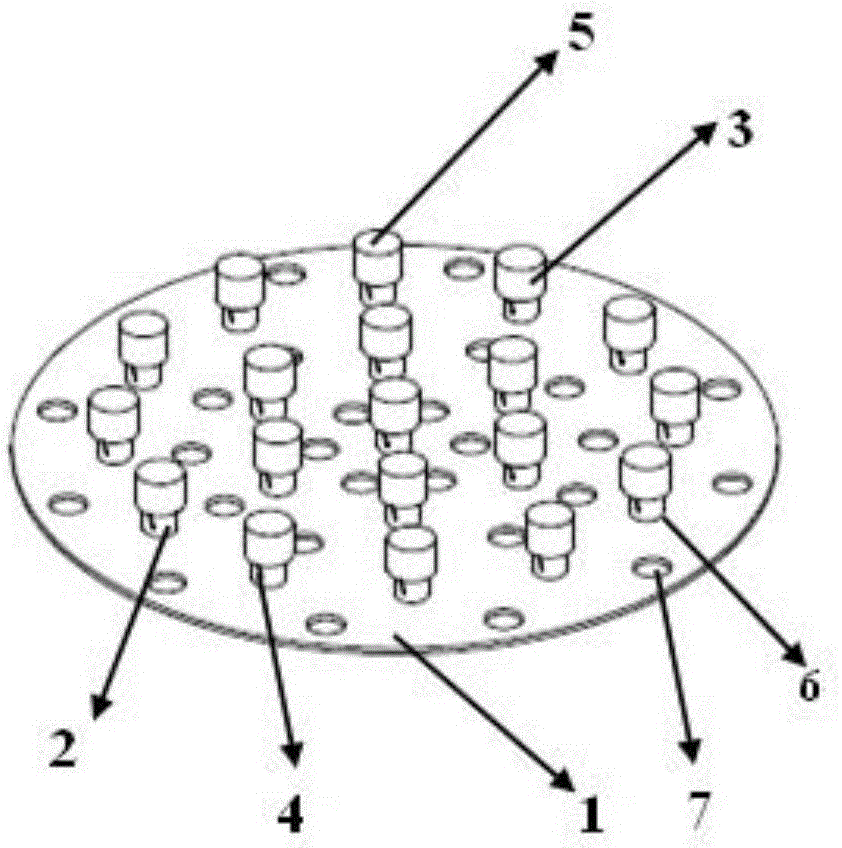

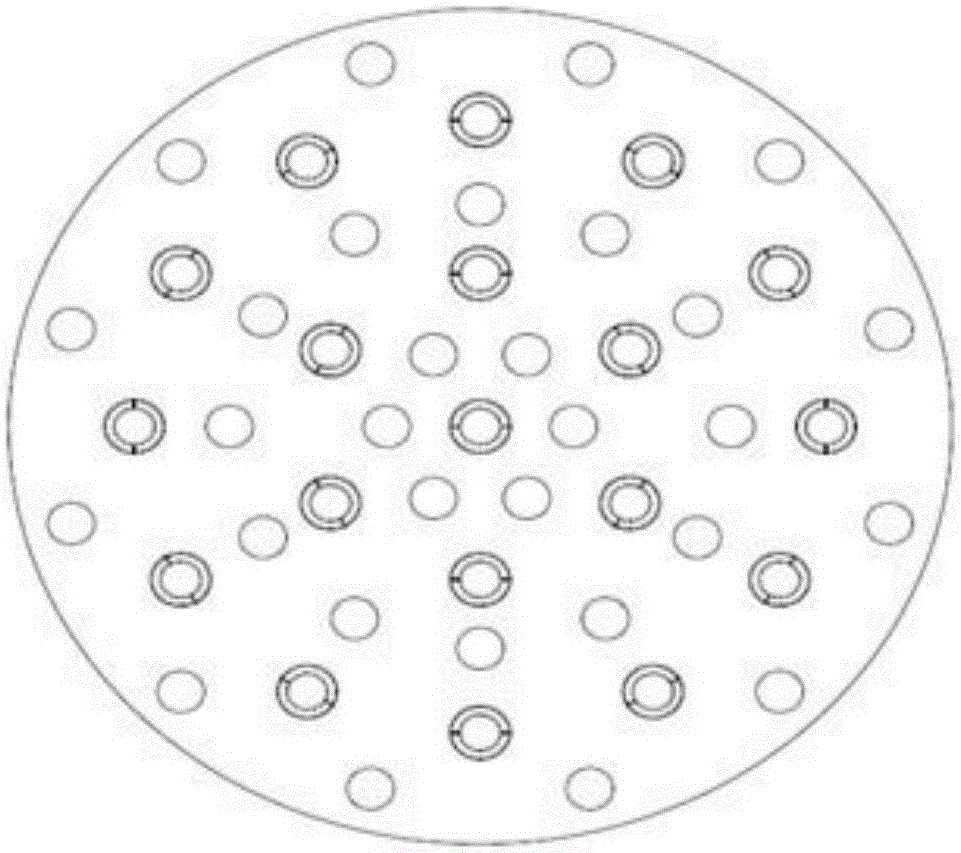

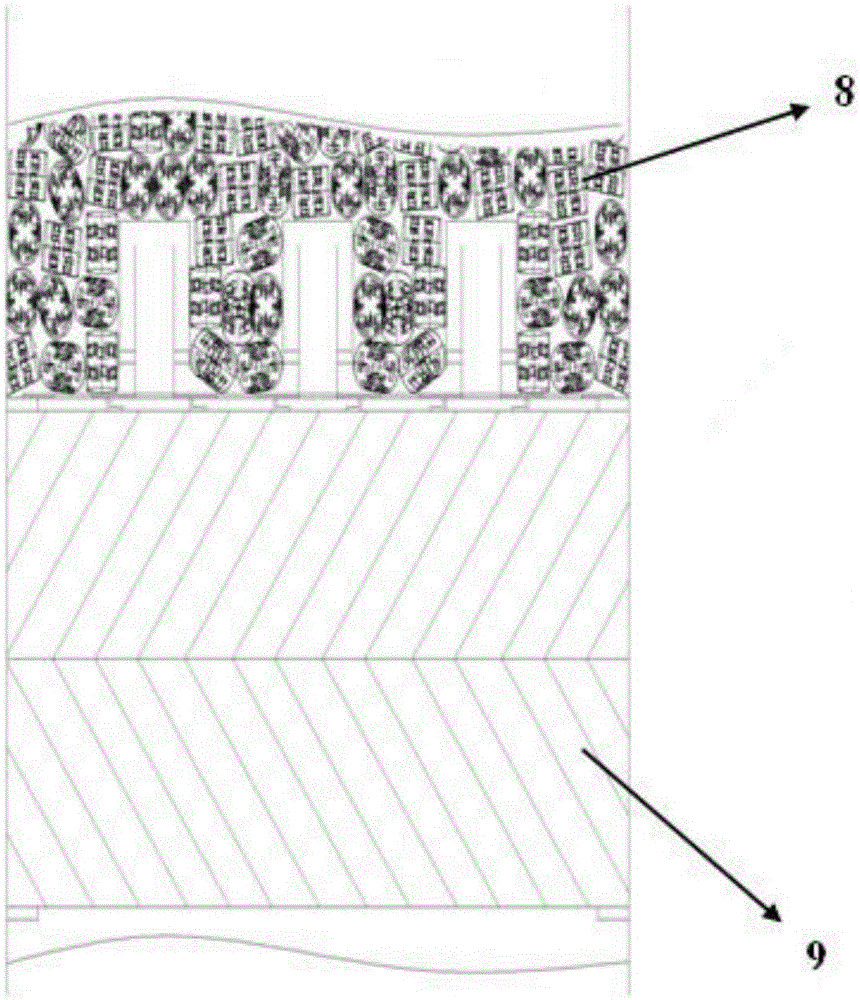

[0027] Such as figure 1 , 2 As shown, a light and heavy phase redistribution device of a liquid-liquid extraction packed tower includes a liquid distribution plate 1, a distribution pipe 2, a distribution pipe cap 3, a distribution pipe cap supporting rib 4, and a blind plate 5 at the upper end of the distribution pipe cap. The liquid distribution plate 1 is circular, and the upper part is evenly distributed with the distribution pipe installation holes 6 for the light phase and the heavy phase distribution holes 7 for the heavy phase, wherein, according to the specific equipment requirements, the distribution pipe installation holes 6 and the heavy phase distribution The unit drop point density per square meter of the hole 7 is appropriately selected within 10-200, and the aperture is appropriately selected within 30-200 mm. Preferably, the unit drop point density pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com