A tool nozzle and its manufacturing method

A nozzle and tool technology, which is applied to the tool nozzle mechanism and its manufacturing field, can solve the problems of inability to clean at a fixed point, prolonged production tact, and inability to fully guarantee the cleanliness of water channels.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

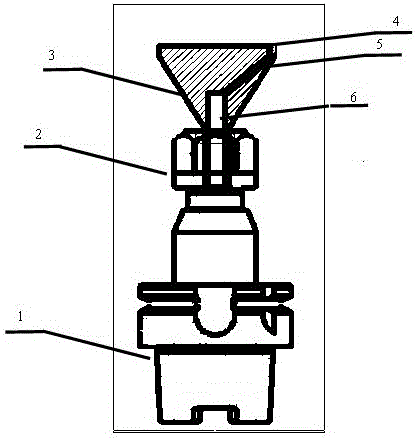

[0022] Below in conjunction with accompanying drawing, preferred embodiment of the present invention is described in further detail:

[0023] Such as figure 1 As shown, a new type of tool nozzle includes a main shaft and a nozzle main body 3, and a handle 1 embedded with the main shaft. A tool seat 2 is arranged between the main body of the spray head 3 and the tool handle 1. Interference fit with the bottom end of the nozzle body 3; the nozzle body 3 is provided with a water outlet hole 4 for cleaning, and a process hole 5 is also arranged below the water outlet hole 4, and the nozzle body 3 is provided with a The process hole 5 communicates with the central hole 6 .

[0024] The new tool nozzle is placed in the tool magazine in a similar way to the tool. When not in use, it is positioned on the tool head by the tool holder. It needs to be placed on the spindle by changing the tool in the NC program. The jaws at the front end of the spindle and The tail of the new tool nozz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com