Aluminum alloy extrusion asymmetric porous mould

A porous mold, asymmetric technology, applied in the direction of metal extrusion mold, metal material coating process, solid diffusion coating, etc., can solve the problems of large difference in flow rate, high scrap rate, uneven wall thickness of profiles, etc. Achieve excellent hardness, increase hardness, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

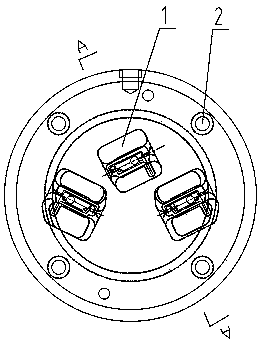

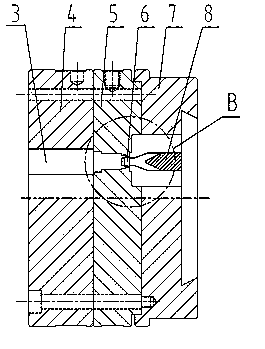

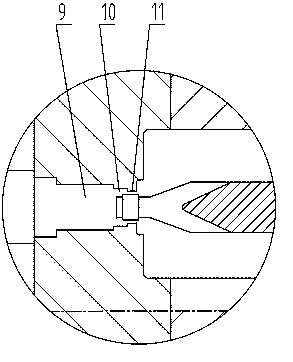

[0034] see as Figure 1-7 As shown, the present invention includes a shunt hole 1, a bolt 2, a discharge hole 3, a mold pad 4, a lower mold 5, a mold core 6, an upper mold 7, a shunt bridge 8, a secondary empty knife 9, a primary empty knife 10, Working belt 11, die hole 12, symmetrical die hole 12.1, asymmetrical die hole 12.2 and welding chamber 13, described upper die 7, lower die 5 and die pad 4 are assembled by bolts 2 in sequence, die pad 4 is set There is a discharge hole 3 corresponding to the die hole, and the upper die 7 is provided with a shunt bridge 8 and a shunt hole 1, and one end of the shunt bridge 8 is provided with a mold core 6 and extends into the lower mold 7, and the shunt hole 1 Distributed on both sides of the shunt bridge 8, the lower mold 5 is sequentially provided with a welding chamber 13, a die hole 12, a primary empty knife 10 and a secondary empty knife 9 from the feed end to the discharge end, and the welding chamber 13 is set at the lower par...

Embodiment 2

[0038] see as Figure 2-8 As shown, the present invention includes a shunt hole 1, a bolt 2, a discharge hole 3, a mold pad 4, a lower mold 5, a mold core 6, an upper mold 7, a shunt bridge 8, a secondary empty knife 9, a primary empty knife 10, Working belt 11, die hole 12, symmetrical die hole 12.1, asymmetrical die hole 12.2 and welding chamber 13, described upper die 7, lower die 5 and die pad 4 are assembled by bolts 2 in sequence, die pad 4 is set There is a discharge hole 3 corresponding to the die hole, and the upper die 7 is provided with a shunt bridge 8 and a shunt hole 1, and one end of the shunt bridge 8 is provided with a mold core 6 and extends into the lower mold 7, and the shunt hole 1 Distributed on both sides of the shunt bridge 8, the lower mold 5 is sequentially provided with a welding chamber 13, a die hole 12, a primary empty knife 10 and a secondary empty knife 9 from the feed end to the discharge end, and the welding chamber 13 is set at the lower par...

Embodiment 3

[0042] see as Figure 2-7 , 9, the present invention includes a shunt hole 1, a bolt 2, a discharge hole 3, a mold pad 4, a lower mold 5, a mold core 6, an upper mold 7, a shunt bridge 8, a secondary empty knife 9, and a first-level empty knife 10. Working belt 11, die hole 12, symmetrical die hole 12.1, asymmetrical die hole 12.2 and welding chamber 13. The upper die 7, lower die 5 and die pad 4 are assembled by bolts 2 in sequence. The die pad 4 is provided with a discharge hole 3 corresponding to the die hole, the upper die 7 is provided with a shunt bridge 8 and a shunt hole 1, and one end of the shunt bridge 8 is provided with a mold core 6 and extends into the lower die 7 Among them, the distribution holes 1 are distributed on both sides of the distribution bridge 8, and the lower mold 5 is sequentially provided with a welding chamber 13, a die hole 12, a first-level empty knife 10 and a second-level empty knife from the feed end to the discharge end. 9. The welding cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com