Feeding device for multi-station internal thread tapping equipment for sleeves

An internal thread, multi-station technology, applied in the field of workpiece material preparation device and machining workpiece material preparation device, can solve the problems of harsh working environment, high labor intensity and low production efficiency of operators, so as to reduce the probability of work-related accidents and reduce The effect of labor intensity and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

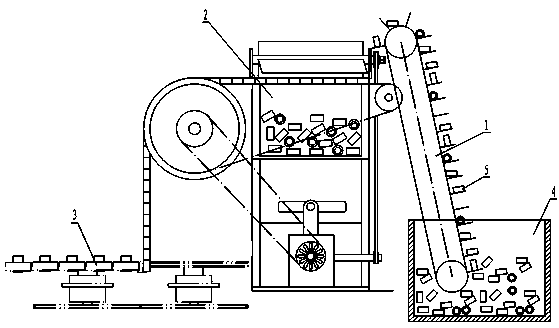

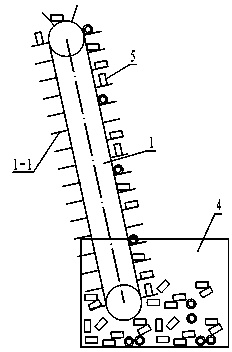

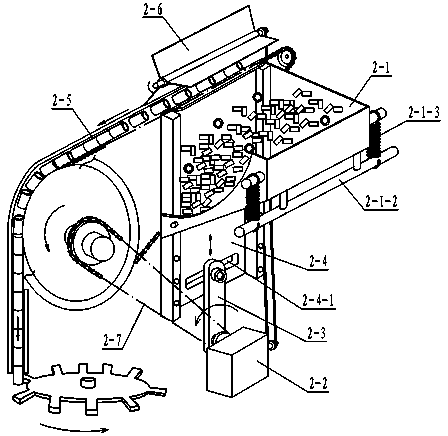

[0022] See Figure 1, figure 2 , the present invention is composed of a workpiece lifting and conveying mechanism 1 and a pallet-type material preparation mechanism 2. The workpiece lifting and conveying mechanism 1 is provided with a scale-type circulating conveyor belt 1-1, and the lower end of the scale-type circulating conveyor belt 1-1 is placed in the workpiece storage In the silo 4, the upper end is located above the hopper 2-1 of the pallet-type material preparation mechanism 2, and the pallet-type material preparation mechanism 2 also includes a reduction motor assembly 2-2, a crank 2-3, a pallet 2-4 and a storage channel 2 -5, the output shaft of the geared motor assembly 2-2 is assembled with the crank 2-3, the geared motor assembly 2-2 drives the crank 2-3 to rotate, and the crank 2-3 is assembled with the supporting plate 2-4, The crank drives the supporting plate 2-4 to move up and down, and the sleeve workpiece 5 in the hopper 2-1 is sent into the storage channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com