Method and cleaning system for cleaning the process gas in soldering installations

一种工艺气体、清洁系统的技术,应用在分离方法、辅助装置、气体处理等方向,能够解决不足、钎焊装置高分子化合物沉积反复发生等问题,达到节约能源的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

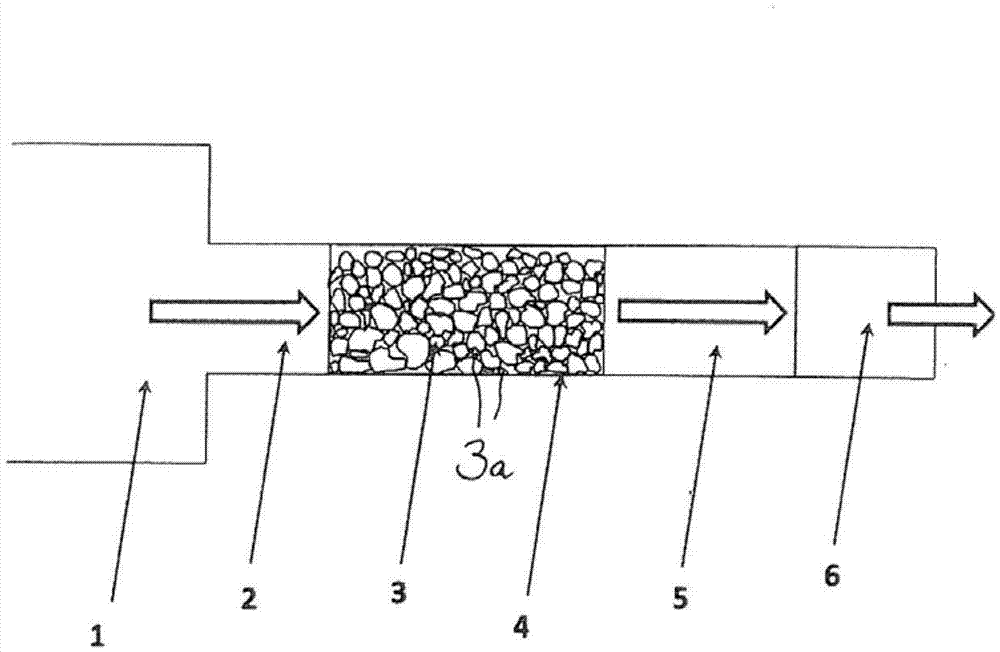

[0037] figure 1 A detail of a brazing installation 1 comprising a cleaning chamber 4 with a cleaning system according to the invention is shown. The clean room 4 contains filter material in the form of Al2O3 particulate matter 3 mixed with oxalic acid 3a.

[0038] To clean the process gas, the process gas is first introduced into a guide 2 , from where the process gas to be cleaned (see arrow) is guided into the cleaning chamber 4 . After leaving the clean room 4 , the process gas is sent via a discharge 5 to a heat exchanger 6 . The cleaned process gas is returned from the heat exchanger 6 to the brazing unit. In this example, the process gas increasingly contains abietic acids from rosin (ie flux). After leaving the clean room, the process gas is practically free of abietic acids. First, this is due to the fact that oxalic acid decomposes abietic acid (in particular, the methyl group of abietic acid is decomposed). The resulting products with low molecular weight do not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com