Device and method for cutting with laser array

A laser array and laser cutting technology, applied in auxiliary devices, laser welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficult matching of different tape widths or sheet specifications, and achieve reduced cost, high reliability and durability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

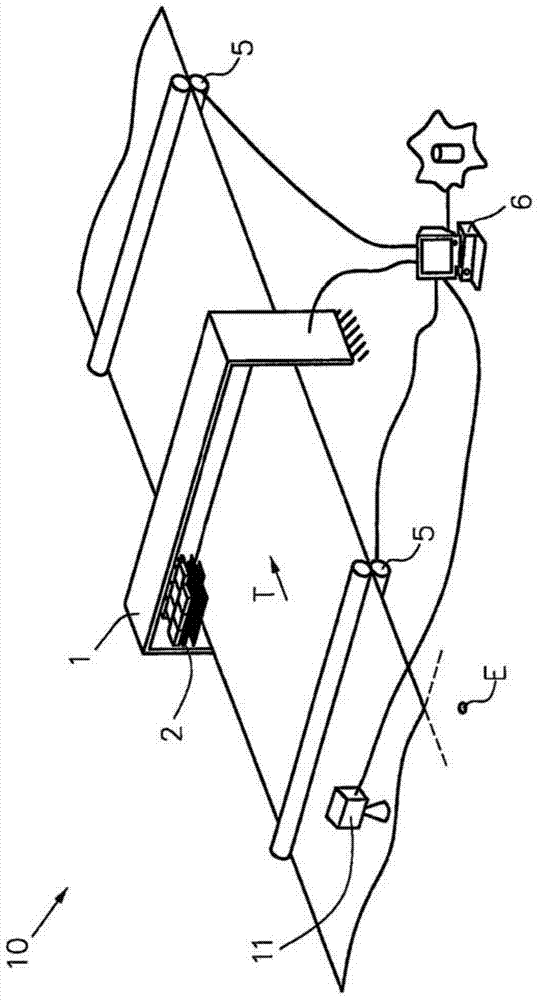

[0023] figure 1 A cutting device 10 is shown for processing strip-shaped substrates 100 . The cutting device 10 has a laser cutting device 1 , a conveying device 5 and a machine control device 6 . The strip-shaped substrate 100 is moved along the transport direction T alongside the laser cutting device 1 by the transport device 15 . In this case, the substrate 100 can be processed by the laser cutting device 1 in the transport plane E, for example by ablation, plunging, contouring or engraving. In this case, the processing is carried out by the laser array 2 of the laser cutting device 1 . The cutting data required for controlling the laser array 2 can be stored in the machine control 6 , can be entered into the machine control, or can be obtained from the machine control via corresponding workflow connections.

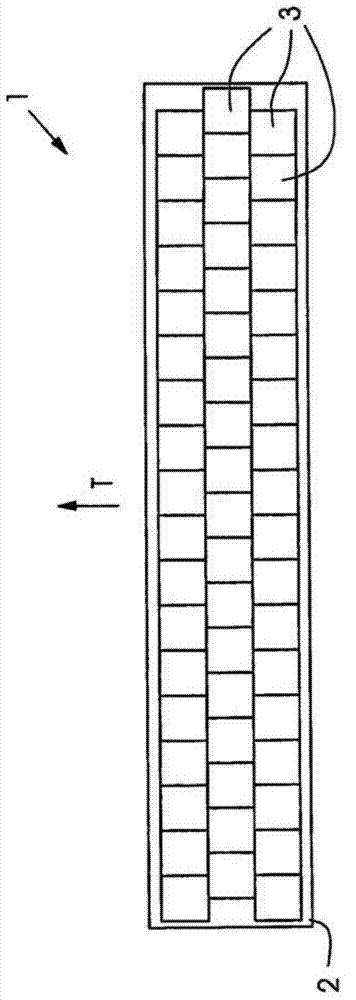

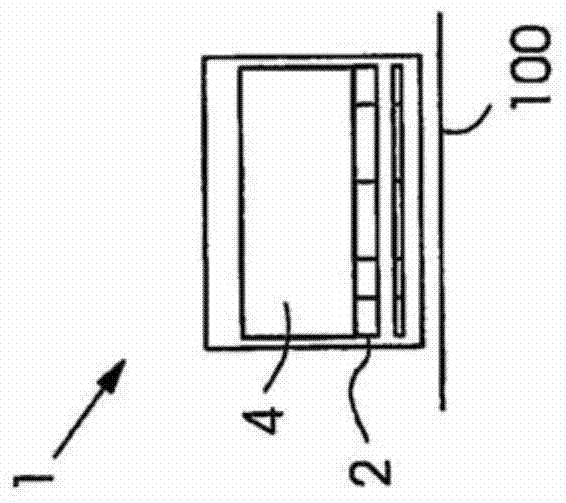

[0024] exist Figure 2a , 2b The structure of the laser cutting device 1 is further shown in and 2c. The laser array 2 is formed from a plurality of individual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com