Method for preparing flat stone by using alternating tensile stress to expand and fracture rock cracks

A technology of crack propagation and tensile stress, applied in the direction of stone processing tools, stone processing equipment, manufacturing tools, etc., can solve the problems affecting the scope of application, and achieve the effect of low production cost, abundant resources, and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

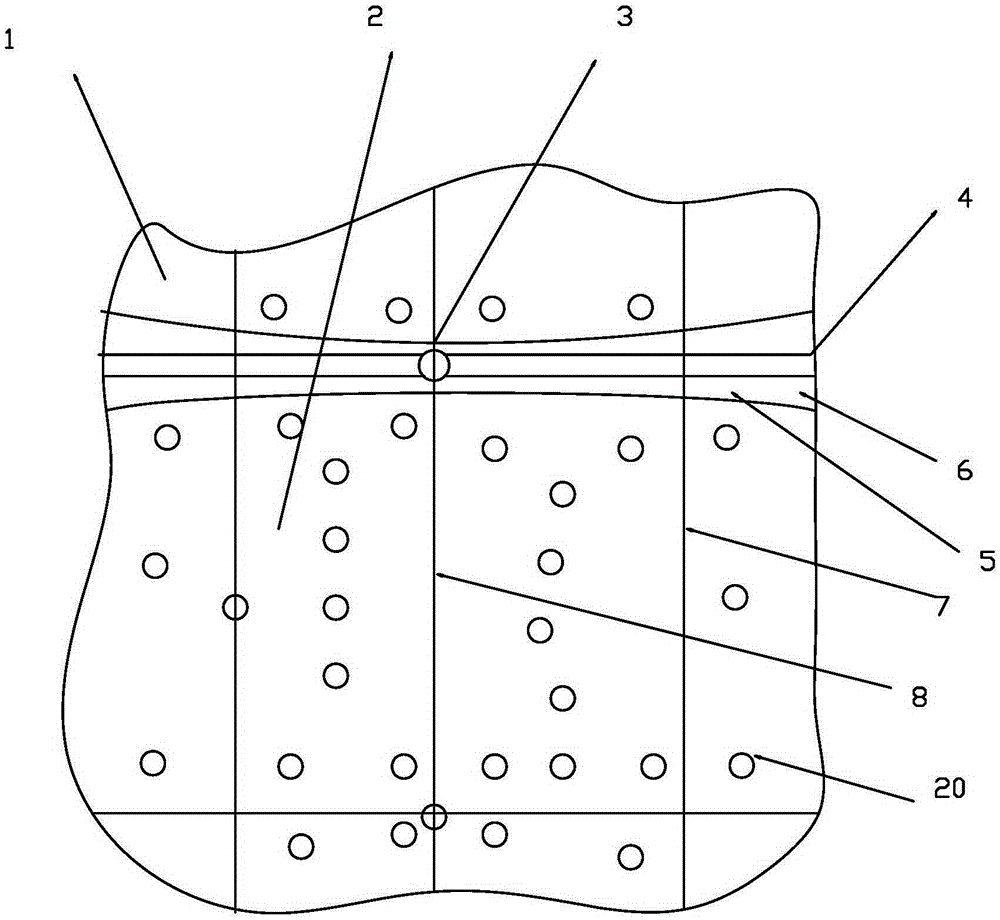

[0033] like figure 1 As shown, the rock mass 1 that is suitable for use as stone is selected. Generally, the top of the rock mass is relatively small, and the horizontal cross-sectional area of the rock mass is larger as it goes downward. Determine a work area at the top to form the first horizontal fracture surface, generally about 20×30 square meters. The rock above the first fracture surface is an irregular rock at the top of the rock mass. After removing the rock, the exposed fracture surface is A preliminary plane. The further down the mining, the larger the horizontal fracture surface. like figure 1 As shown, the horizontal fracture surface to reach 100×100 square meters is taken as an example. During processing, the working plane is first formed: the formed flat stone is divided and transported away to expose the working plane forming the next horizontal fracture surface.

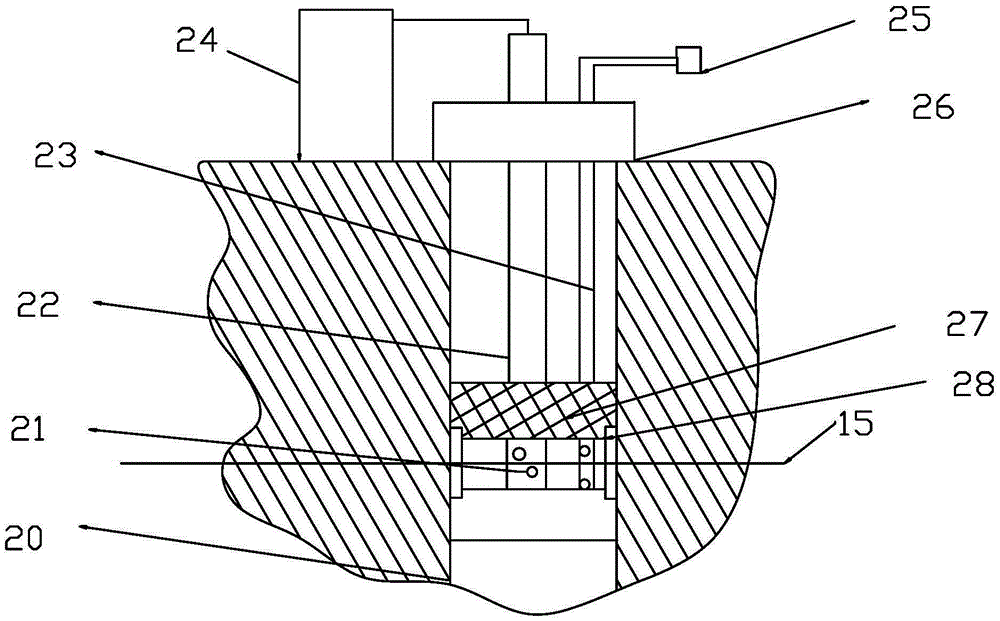

[0034] On the working plane, according to the hardness of the rock mass, an approximately r...

Embodiment 2

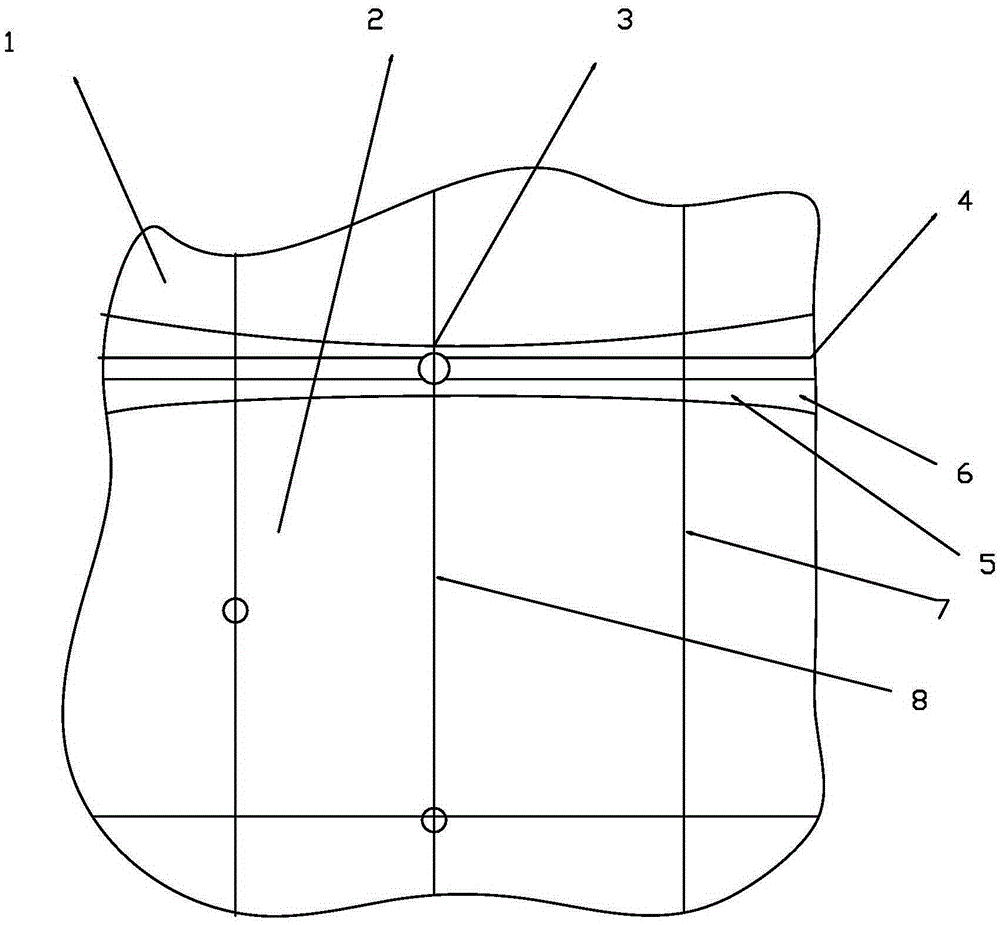

[0044] In this embodiment, vertical alternating tensile stress is used to initiate and propagate cracks. There are two points of difference between this embodiment and embodiment 1: the one is that this embodiment forms as image 3 In the shown crack groove, the alternate tensile stress hole and the alternate tensile stress generator used in Embodiment 1 are cancelled. Second, the embodiment forms image 3 After the crack groove shown, on the outer side of the outer ring crack groove at both ends of the crack groove, a motor vehicle equipped with a percussion hammer is arranged according to a distance of 4-7 meters. The end of the percussion hammer is made of wood, and the hammer weight is 50-300 kg. Make a vertical reciprocating motion, the number of impacts per minute is 20-50 times, impact the rock above the crack, and gradually push the impact point forward as the crack expands, so that the crack forms a fracture surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com