Thermoplastic fiber winding pipe equipment and applications thereof

A thermoplastic fiber and pipe winding technology, applied in the field of thermoplastic fiber winding pipe equipment, can solve the problems of poor impact resistance and non-recyclability, and achieve the effects of short molding cycle, light weight and simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

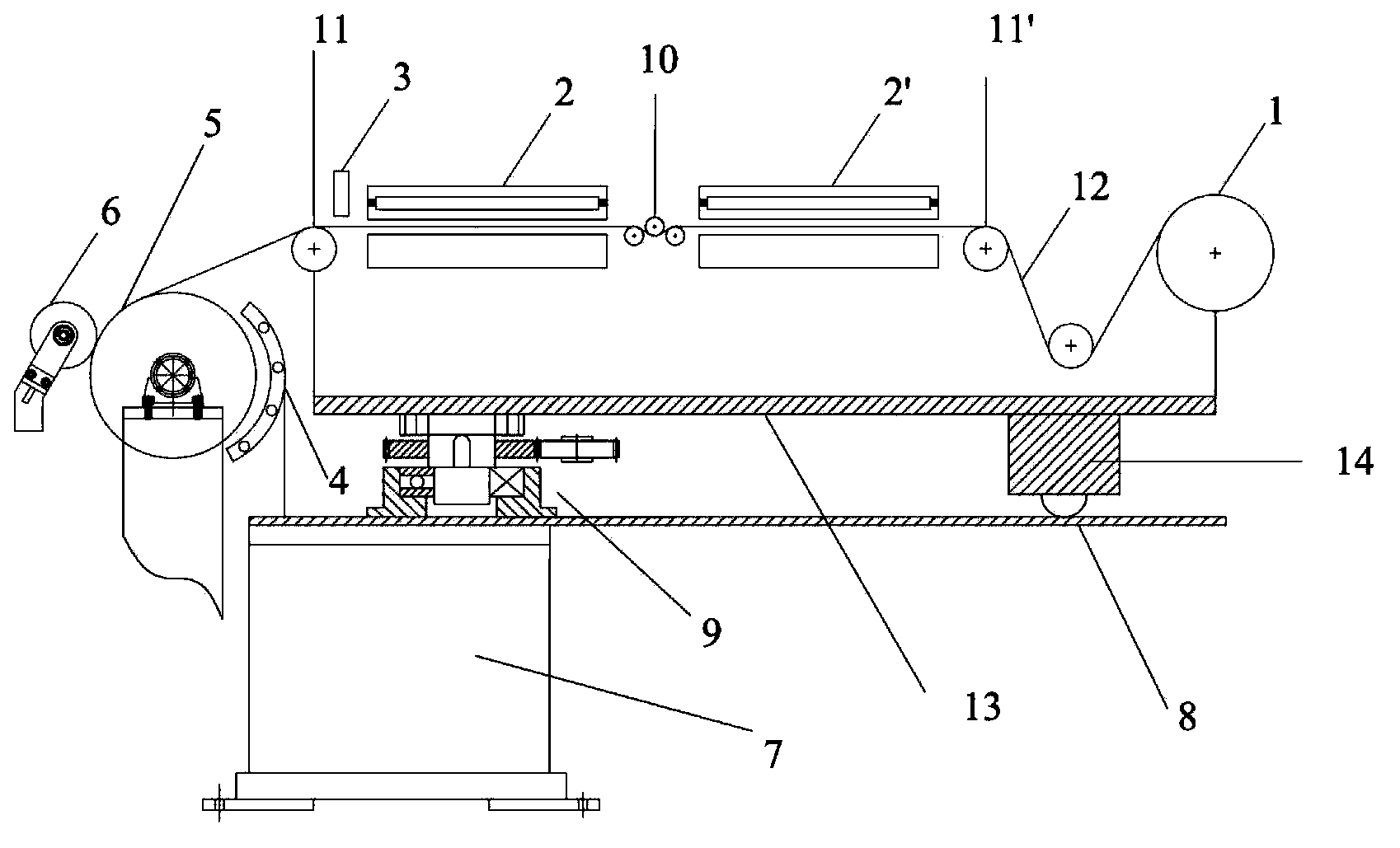

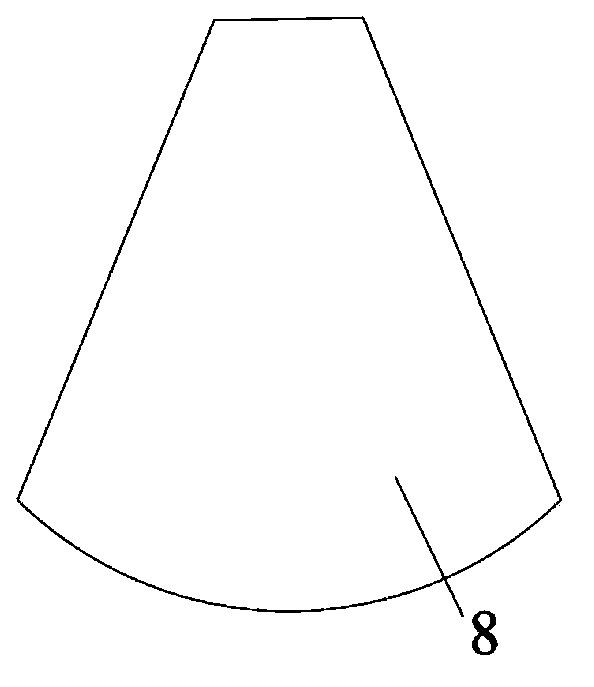

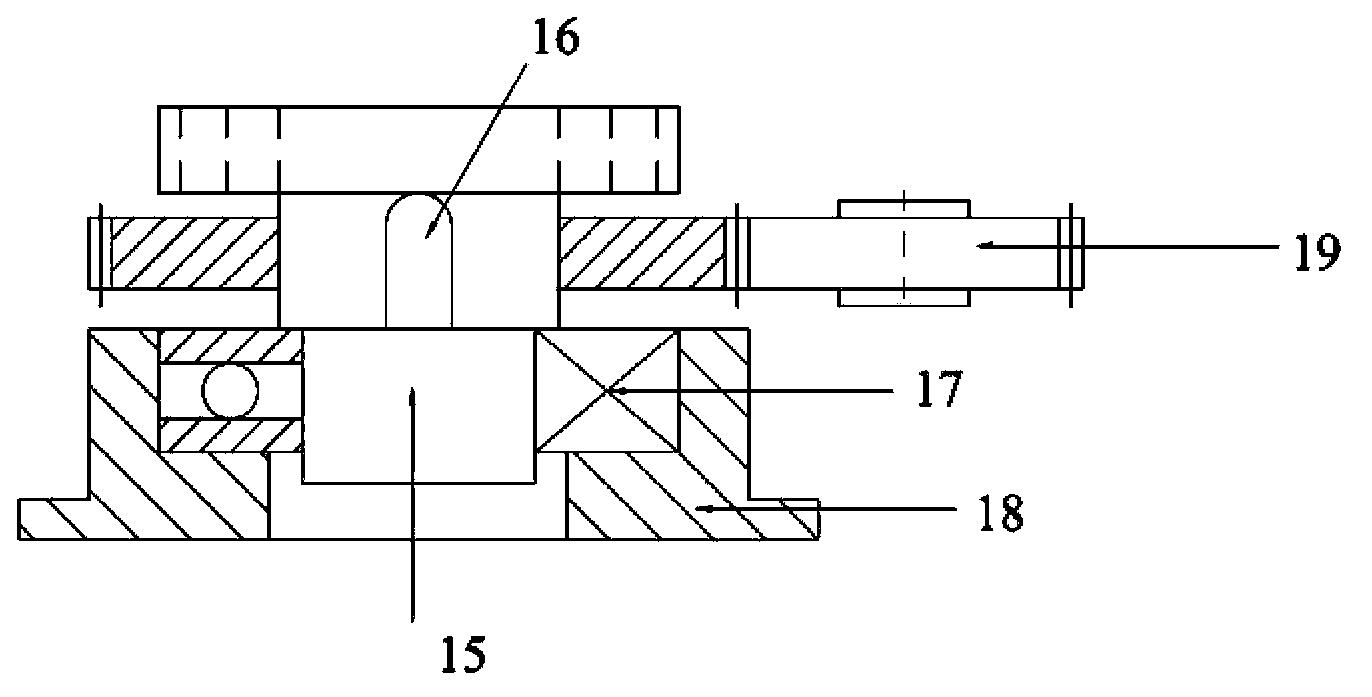

[0040] A thermoplastic fiber winding pipe equipment, comprising: an unwinding device 1, a first infrared heater preheating device 2, a second infrared heater preheating device 2', an infrared thermometer 3, a core mold infrared heater 4, a core Die 5, pneumatic pressure roller 6, frame 7, trolley 8, horizontal rotating shaft 9, tension meter 10, first guide roller 11, second guiding roller 11', bearing plate 13, supporting ball 14, of which the horizontal rotating shaft 9 It is made up of rotating shaft 15, key 16, thrust bearing 17, bearing seat 18, gear 19.

[0041] The frame 7 is the bearing part of the thermoplastic fiber winding pipe equipment, and is mainly used for installing the trolley 8, the mandrel 5, the unwinding device 1, the first infrared heater preheating device 2, and the second infrared heater preheating device 2' , mandrel infrared heater 4, infrared thermometer 3, tensiometer 10, pneumatic pressure roller 6, horizontal rotating shaft 9 and first guide roll...

Embodiment 2

[0046] A thermoplastic fiber winding pipe equipment, its use method is: use continuous carbon fiber reinforced nylon prepreg tape to wind the pipe, and before the winding starts, the core mold 5 is preheated by the core mold infrared heater 4, so that the surface temperature of the core mold When it reaches 150°C, turn off the heater temporarily, and wrap a layer of PET film on the surface of the mandrel, and the mandrel heater will keep heating during the winding process. Then the tape is unwound by the unwinding device 1, and the prepreg tape is drawn to the winding starting end of the mandrel through the first guide roller 11 and the second guide roller 11' and fixed. Then turn on the mandrel heater again, the temperature guarantees that the prepreg tape wound on the mandrel can be completely melted, and open the first infrared heater preheating device 2 and the second infrared heater preheating device 2', and pass the infrared thermometer 3. Measure the surface temperature...

Embodiment 3

[0048] A thermoplastic fiber winding pipe equipment, its use method is: use continuous aramid fiber reinforced polyethylene terephthalate prepreg tape to wind the pipe, and before the winding starts, 4 pairs of mandrels are passed through the mandrel infrared heater 5 Preheat to make the surface temperature of the mandrel reach 140°C, then temporarily turn off the heater, and wrap a layer of PET film on the mandrel surface, and the mandrel heater keeps heating during the winding process. Then the tape is unwound by the unwinding device 1, and the prepreg tape is drawn to the winding starting end of the mandrel through the first guide roller 11 and the second guide roller 11' and fixed. Then turn on the mandrel heater again, the temperature guarantees that the prepreg tape wound on the mandrel can be completely melted, and open the first infrared heater preheating device 2 and the second infrared heater preheating device 2', and pass the infrared thermometer 3. Measure the surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com