Environment-friendly electromagnetic shielding coating for inner walls of buildings and preparation method thereof

An electromagnetic shielding coating and building technology, applied in conductive coatings, coatings and other directions, can solve problems such as harm, affecting the cardiovascular system, children suffering from leukemia, etc., to reduce environmental pollution and public hazards, save resources and energy, and electrical conductivity. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

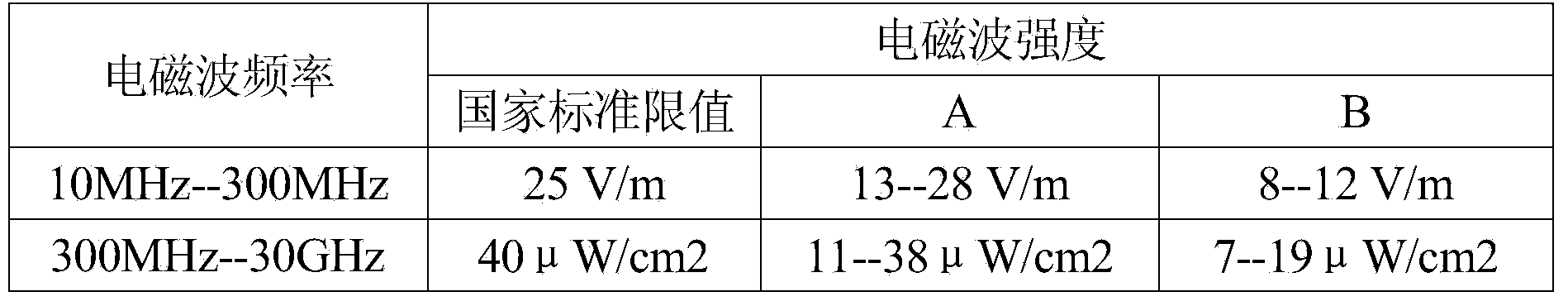

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Environmentally-friendly electromagnetic shielding paint for interior walls of buildings, which includes the following components by weight: It includes the following components by weight percentage: water-based acrylic resin 20%, conductive mica 60%, graphite 10%, carbon black 7 %, 2% hydroxyethyl cellulose, 1% silicone coupling agent.

[0035] Weigh the water-based acrylic resin, conductive mica, graphite, carbon black, hydroxyethyl cellulose, and silicone coupling agents respectively according to mass percentages; weigh the conductive mica, silicone coupling agent, and hydroxyl Add ethyl cellulose to the water-based acrylic resin and fully stir it with a blender for 20 minutes. In this step, the silicone coupling agent is used to treat the surface of the conductive mica powder; graphite and carbon black are added to the paint separately and fully stirred for 10 minutes; The pre-mixed paint is made 3 times with a three-roller rail machine. The three steel roll...

Embodiment 2

[0037] Environmentally-friendly electromagnetic shielding paint for interior walls of buildings, which includes the following components by weight: It includes the following components by mass percentage: 24% water-based acrylic resin, 50% conductive mica, 9% graphite, 12% carbon black, hydroxypropyl Base methyl cellulose 3%, titanate lipid coupling agent 2%.

[0038] Weigh the water-based acrylic resin, conductive mica, graphite, carbon black, hydroxypropyl methylcellulose, and titanate ester coupling agents respectively according to mass percentages; the weighed conductive mica and titanate ester coupling agents Add the coupling agent and hydroxypropyl methyl cellulose to the water-based acrylic resin, and stir it with a mixer for 20 minutes. In this step, the titanate ester coupling agent is used for surface treatment of the conductive mica powder; graphite and carbon black are added to the coating separately , Fully agitate for 10 minutes; use a three-roller rail machine to m...

Embodiment 3

[0040] Environmentally-friendly electromagnetic shielding coating for interior walls of buildings, which includes the following components by weight: It includes the following components by mass percentage: water-based acrylic resin 27%, conductive mica 52%, graphite 5%, carbon black 10%, methyl Cellulose 5%, silicone coupling agent 1%.

[0041] Weigh the water-based acrylic resin, conductive mica, graphite, carbon black, methyl cellulose, and silicone coupling agents respectively according to mass percentages; weigh the conductive mica and silicone coupling agent, methyl Add the cellulose to the water-based acrylic resin and fully stir it with a mixer for 20 minutes. In this step, the silicone coupling agent will surface the conductive mica powder; add graphite and carbon black to the paint separately, and fully stir for 10 minutes; The paint is made 3 times by a three-roller rail machine. The three steel rollers of the three-roller rail machine rotate at a high speed to generat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com